Aluminum circle for road sign refers to the aluminum circle used in the production of road signs. Because aluminum circles have strong corrosion resistance and weather resistance, aluminum circles are very suitable for the production of road signs.

Aluminum circle for road sign refers to the aluminum circle used in the production of road signs. Because aluminum circles have strong corrosion resistance and weather resistance, aluminum circles are very suitable for the production of road signs.

Aluminum circle for road sign

Road sign materials must meet specific requirements to ensure visibility, durability, and safety on the road. These requirements are typically defined by national and regional standards, such as the Manual on Uniform Traffic Control Devices (MUTCD) in the United States. The following are common material requirements for road signs:

Aluminum: Aluminum is the most commonly used material for road signs. It offers durability, corrosion resistance, and ease of fabrication. The aluminum used for road signs is often of high quality, such as 5052-H38 or 6061-T6 alloys.

Reflective Sheeting: Aluminum disc circle for traffic sign must use reflective sheeting to enhance visibility, especially at night or in adverse weather conditions. There are various types of reflective sheeting, including:

Size and Shape: Road signs come in various sizes and shapes, and these are often defined by regulatory standards. The size and shape should be appropriate for the type of message the sign conveys and the speed of traffic.

Font and Typeface: The font used for text on road signs should be highly legible. Standards often dictate the typeface and letter height to ensure readability.

Aluminum circle for road sign application

Graffiti Resistance: To maintain visibility and aesthetics, road signs should be resistant to graffiti and easy to clean.

Weather Resistance: Road signs are exposed to various weather conditions. The material and coatings used should be able to withstand sunlight, rain, snow, and temperature fluctuations without significant deterioration.

Mounting and Attachment: Road signs need to be securely mounted to signposts or structures. This may involve holes for fasteners, brackets, or other attachment mechanisms. These must meet specified standards for stability and security.

Durability and Lifespan: Road signs are expected to have a long lifespan, typically several years. The materials used should be durable to minimize the need for frequent replacement.

Retroreflectivity Standards: Many regions have standards specifying the minimum levels of retroreflectivity that road signs must maintain. Signs should be regularly inspected and replaced if they fall below these levels.

Regulatory Compliance: Road signs must adhere to local and national regulations regarding design, installation, and maintenance. These regulations are often outlined in documents like the MUTCD in the United States.

Aluminum circle for road sign production

Sustainability: Some regions may require consideration of environmental factors and the use of sustainable materials in road sign construction.

These requirements are in place to ensure the effectiveness of road signs in conveying important information to drivers, pedestrians, and other road users. Adhering to these standards helps maintain safety and order on the road. It’s essential to consult the relevant regulatory authorities and guidelines to ensure that road signs meet the specific requirements of the location where they will be installed.

Aluminum circles have various features that make them a versatile and useful material for a wide range of applications. These features are attributed to the properties of aluminum itself, and they make aluminum circles ideal for specific uses, including in the production of cookware, lighting fixtures, road signs, and more. Here are some key features of aluminum circles:

Lightweight: Aluminum is a lightweight material, which is one of its most significant advantages. This property makes aluminum circles easy to handle, transport, and install, making them suitable for applications where weight is a concern.

Corrosion Resistance: Aluminum naturally forms a protective oxide layer on its surface, which makes it highly resistant to corrosion. This corrosion resistance is especially important in outdoor or wet environments.

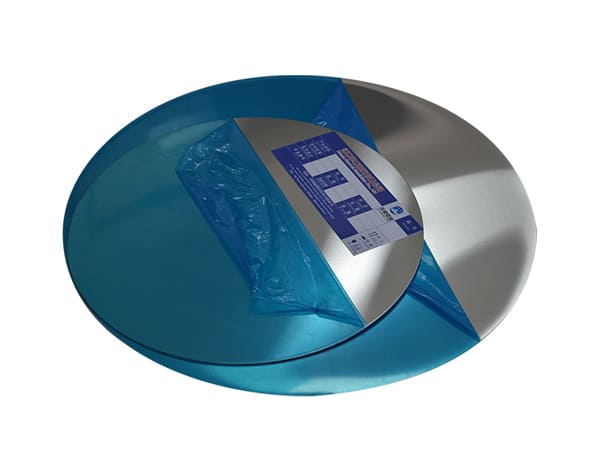

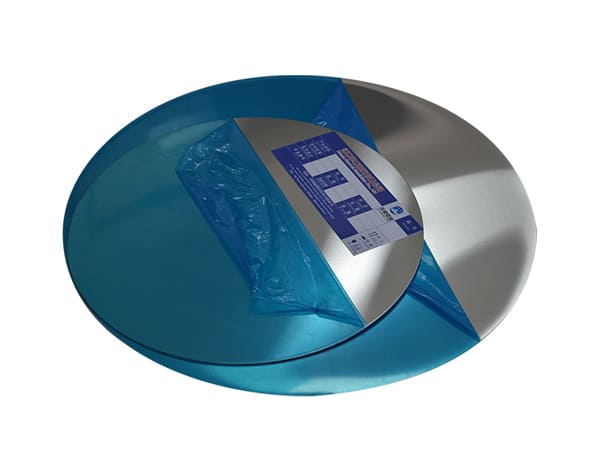

Aluminum circle packaged

Thermal Conductivity: Aluminum is an excellent conductor of heat. This feature makes it ideal for applications such as cookware and heat sinks, where efficient heat transfer is essential.

Electrical Conductivity: Aluminum is also a good conductor of electricity, making it valuable for electrical applications like wiring and conductors.

Malleability: Aluminum is a highly malleable material, which means it can be easily shaped, formed, and stamped into various designs. This makes it suitable for manufacturing a wide range of products with intricate shapes.

Ductility: Aluminum is a ductile material, allowing it to be stretched or drawn into thin wires or sheets. This property is valuable in the production of aluminum foil and similar products.

Recyclability: Aluminum is highly recyclable, and recycling it requires significantly less energy than producing new aluminum. This feature makes aluminum an environmentally friendly material and contributes to sustainability efforts.

Strength: While aluminum is not as strong as some other metals like steel, it still offers sufficient strength for many applications. Different aluminum alloys can be chosen for specific strength requirements.

Non-Toxic: Aluminum is non-toxic and food-safe, making it suitable for use in cookware and food processing applications.

Aesthetics: Aluminum has a clean, modern appearance that can be easily customized through various finishes, coatings, and colors.

Low Maintenance: Aluminum is relatively low-maintenance, as it doesn’t require painting or surface treatment to prevent corrosion. It retains its appearance over time, reducing the need for ongoing maintenance.

Versatility: Aluminum circles can be used in a wide range of industries and applications, including aerospace, construction, automotive, electronics, and more.

Color coated aluminum circle

Reflectivity: Some aluminum alloys are highly reflective and are used in applications such as road signs and lighting fixtures to enhance visibility.

Chemical Resistance: Aluminum is resistant to many common chemicals, which is beneficial in industrial and chemical processing applications.

Sound Dampening: Aluminum can help dampen vibrations and reduce noise in certain applications.

These features, along with the ability to customize aluminum circles through various alloys and treatments, make them an attractive choice for many manufacturers and designers seeking lightweight, durable, and versatile materials for their products and projects.

| Alloy | A1100, A1050, A1070, A1060, A3003, A5052, A5083, A6061, etc. |

| Temper | O, H12, H14, H16, H18, T3, T6, T651, etc. |

| Thickness | 0.4mm to 20mm |

| Diameter | 20mm to 1500mm |

| Technology | CC and DC quality |

Based on the above demand characteristics of road sign materials and the characteristics of aluminum circles, it can be concluded that aluminum wafers are the best material for making road signs. If necessary, special surface treatments can be performed, such as polishing, color coating, spraying, polishing, etc. .

As a company with 22 years of experience in the production and sales of aluminum circles, Huawei is able to provide high-quality

Mirror aluminum circle

Color coated aluminum circle

Punched aluminum circle

The alloy, thickness, and size of aluminum circles can for road sign be customized according to customer needs.

Aluminum circle for road sign can not only be used to make road signs but also has many other uses, such as:

Aluminum circle other applications

Cooking utensils

Pizza plate

Pot

Lampshade

Road sign

Garnish

Electronic product

3000 series aluminum alloy is an AL-MG alloy whose main components are aluminum, manganese and a small amount of other elements. It has excellent properties such as good corrosion resistance, processability and weldability.

Aluminum alloy 8011 aluminum foil is widely used in aluminum-plastic composite board base tape and food packaging. As a professional aluminum foil 8011 manufacturer in China, Huawei Aluminum has a large 8011 aluminum foil production base and has accumulated more than 20 years of rich aluminum foil production experience and skilled processing technology.

0.75 aluminum sheet refers to an aluminum sheet with a thickness of 0.75 inches, also known as 0.75" aluminum sheet;

Aircraft Grade Aluminum Sheet Plate is an alloy that has undergone special treatment such as high-temperature oxidation, and can withstand thousands of degrees of high temperature or strong impact.

The 6063 aluminum sheet is a 6000-series aluminum alloy with magnesium and silicon as the main alloying elements. The strength of the 6063 alloy is lower than that of the 6061 alloy, and it has good extrudability, corrosion resistance, and good surface treatment performance.

6061 aluminum coil" is an aluminum alloy that is commonly used for applications such as automotive and aerospace components, as well as for construction and industrial products. This article will explore the Properties,Benefits and Applications of 6061 aluminum coil, from its raw material form to the finished product.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

Dear Sirs, I'm looking for a provider of aluminum 7075-T651 in 1.0 or 1.5 mm thickness. We need about 180 plates of 200 mm x 200 mm. Are you able to provide a quote and delivery time for this? Thank you so much in advance. Kind regards, Francisco Silva

Hello, I hope this message meets you well. I have perused your website and I want a detailed price quote for your product; upon your response to this message I will forward more details concerning this order/project to you. I look forward to doing business with you. Warm thanks. Best regards, Ahmet Emir Purchase Manager SER MEKATRONIK SANAYI VE TICARET LTD.STI. Turkgucu O.S.B. Mahallesi 216.Sokak NO:5/1 Corlu / Tekirdag / Turkey Email: [email protected]

I need a quotation for 3000 series aluminum sheets/coils (3104 H19) for tuna can production, food-grade finish, delivery to Mazatlán, Mexico.

I am planning a business trip to China and I am very interested in your aluminium 8011 products for food container production. I would like to visit your factory during my stay in china: See your production lines (foil rolling, annealing, slitting, packing). Discuss specifications (8011-O temper, thickness 0.05–0.08 mm, jumbo roll). Review your quality certificates and export experience. Could you please let me know: Your available dates for a visit The location of your factory If you can provide an invitation letter for my business visa (M visa). Thank you for your kind support. Looking forward to your reply. Best regard: LOUNIS MUSTAPHA company name:TOP BARQUETTE SELECT [email protected] what's up:213 770 91 69 43

Merhaba ; Burak ÜNAL ben. Antalya ' da Ambalaj ve Temizlik ürünleri tedarik eden bir firmanın yetkilisiyim. Ayrıca P.E Streç aktarım işi yapmaktayım. Makinalarımızı 9 ve 10 micron alüminyum folyo aktarımına uyacak şekilde revize edeceğiz. Sizden istediğim, 9 veya 10 micron olacak şekilde 35 cm ve 45 cm jumbo folyolar için fiyat, termin ve şu bilgileri istiyorum ; 35 cm jumbo folyonun ortalama ağırlığı. 45 cm jumbo folyonun ortalama ağırlığı. Deneme olacağı için bu 2 ölçüde minimum sipariş tonajımız ne kadar olması gereklidir. İyi çalışmalar.