Aircraft grade aluminum sheet is a type of aluminum alloy that is specifically designed for use in aerospace applications. These sheets are made from high-strength aluminum alloys that are lightweight yet strong enough to withstand the stresses and strains of flight.

Aircraft grade aluminum sheet is a type of aluminum alloy that is specifically designed for use in aerospace applications. These sheets are made from high-strength aluminum alloys that are lightweight yet strong enough to withstand the stresses and strains of flight.

Aircraft Grade Aluminum Sheet

Aircraft grade aluminum sheets are used in the construction of various parts of an aircraft, including the fuselage, wings, and other structural components. They are also used in the production of aircraft skins and panels, where their strength and durability are essential for maintaining the structural integrity of the aircraft.

Aluminum alloys make up 75 to 80 % of modern aircraft and have been used for this purpose since the dawn of powered flight.

The reason is that aircraft require strong yet lightweight materials.

Because aluminum aerospace parts are about one third the weight of steel, which allows aircraft to carry more weight and be more fuel efficient than they could be if built with heavier material. In addition, the high corrosion resistance of aluminum is essential for aircraft safety.

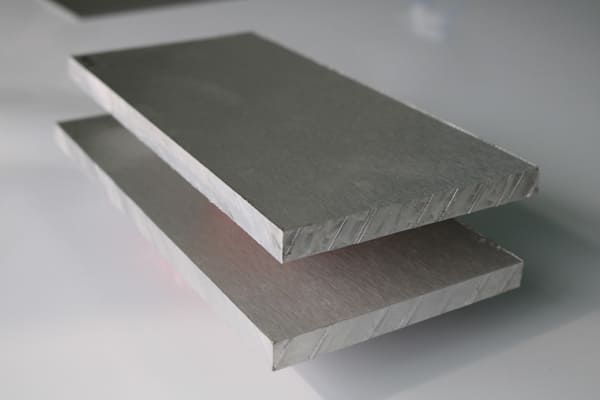

Aircraft grade aluminum sheet plate has excellent strength-to-weight ratio, corrosion resistance and other properties that make it suitable for aerospace applications. Some common aluminum alloys used for aircraft grade sheets and plates include:

The following is a detailed introduction to aircraft grade aluminum sheet plate.

| Alloy | Thickness | Temper | Application |

| 2024 | 0.3-260mm | T351, T3, T4 | Fuselage skins, skins for aircraft, thin-walled components, honeycomb sandwich panel etc. |

| 3003 | 0.3-260mm | O, H14, H16, H18, H22, H24, H26 | Cowls and baffle plating |

| 5052 | 0.3-300mm | O, H32, H112,H122,H116,H321,H323 | Fuel tanks |

| 6061 | 4-260mm | T651, T6 | Aircraft elevators |

| 6082 | 0.5-300mm | O, T4, T6, T651, T6511 | Aviation engines, leather panels, cabin interiors, seat structures, fuselage structures, wing structures, propellers, fuselage shells, suspension brackets, engine brackets |

| 7075 | 0.5-260mm | T6, T651, T7651, T7351 | Fuselage skins, aviation thin-walled parts, wing panels, aviation sandwich panels, aircraft wing siding, aircraft lip grille |

2024 aircraft grade aluminium belongs to high-strength aluminum, and has a certain degree of heat resistance, good forming properties in hot, annealed and newly quenched states. The heat treatment strengthening effect of 2024 aluminum sheet is significant, but the heat treatment process is strict.

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Zr | Ti | Al |

| 2024 | 0.50 | 0.50 | 3.8-4.9 | 0.30-0.90 | 1.20-1.80 | 0.10 | 0.25 | – | 0.15 | Remainder |

2024-T351 thick plates used for aircraft wing panels.

2024 Aircraft Grade Aluminum Sheet

Thin 2024 aluminum sheet for fuselage skins and other aviation uses.

2024 aviation aluminum sheet finds its applications in fuselage skins, skins for aircraft, thin-walled components, honeycomb sandwich panel etc.

The main alloying elements in 6061 aircraft grade aluminium alloy are magnesium and silicon, which have medium strength, good corrosion resistance, welding ability and good oxidation effect.

6061 alloy Aircraft Grade Aluminum Sheet

6061 t6 aircraft grade aluminum is widely used in various industrial structural parts that require certain strength and high antimicrobial corrosion. 6061 aluminum plate has no stress-resistance corrosion cracking tendency, good welding performance, good forming ability, and good process performance. It is used in aircraft elevators and other fields.

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Zr | Ti | Al |

| 6061 | 0.40-0.80 | 0.70 | 0.15-0.40 | 0.15 | 0.80-1.2 | 0.04-0.35 | 0.25 | – | 0.15 | Remainder |

| Mechanical Property | Value |

| Proof Stress | 240 Min MPa |

| Tensile Strength | 260 Min MPa |

| Hardness Brinell | 95 HB |

In the aerospace industry, 6082 aviation aluminum plates produced by A96082, BS L113, BSL115, BS HP30, BS HS30 etc standards have the characteristics of high strength, good processing performance, corrosion resistance and welding performance. Planting aviation equipment and aviation structures.

6082 aviation-grade aluminum plate has high strength, about 20% higher than ordinary industrial aluminum alloys, meeting the demand for high-strength materials in the aviation field.

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

| 6082 | 0.7-1.3 | 0.50 | 0.10 | 0.40-1.00 | 0.06-1.20 | 0.25 | 0.20 | 0.10 | Remainder |

| Material | Thickness (mm) | Tensile strength (N/mm2) min | Yield strength (N/mm2) min | Elongation on 50mm % (min) |

| Alloy 6082 T6 Sheet and Plate | 0.2-3.0 | 295 | 255 | 8 |

| 3.0-6.0 | 240 | |||

| 6.0-25.00 | 240 |

7075 aircraft aluminum sheet is a kind of zinc-magnesium aluminum alloy, which is the most common aluminum alloy with the best strength. 7075 t6 aircraft aluminum sheet is one of the strongest commercial alloys, with good mechanical properties and anode reaction.

Aircraft Grade (7075 alloy) Aluminum Sheet

Other tempers of 7075 aircraft aluminum include T651, T7651 and T7351. But it cannot be welded, and its corrosion resistance is relatively poor. In terms of hardness, 7075 aircraft aluminum is the top grade among 7 series aluminum alloys, suitable for making aircraft structures and high-strength accessories.

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Zr | Ti | Al |

| 7075 | 0.40 | 0.50 | 1.2-2.0 | 0.30 | 2.1-2.9 | 0.18-0.28 | 5.1-6.1 | – | 0.20 | Remainder |

Because of copper, it is difficult but not impossible to weld.

| Alloy-Temper | Thickness (mm) | Tensile strength | Yield Strength | Breaking Elongation | Standard |

| 7075-T651 | 6-260 | 570-590Mpa | 495-515Mpa | 10-13.5 | GB/T3880 |

| 7075-T7651 | 6-102 | 550-560Mpa | 480-490Mpa | 10.5-12.5 | AMS4045K |

| 7075-T7351 | 6-102 | 500-520Mpa | 420-435Mpa | 10-12.5 | AMS4078 |

The three most used are 6061, 7075 and 2024 clad.

6061 is alloyed with magnesium and silicon, is easy to machine and can be easily welded. 7075 has zinc as its main alloy and has high strength, but cannot be effectively welded. 2024 is by far the most popular choice for skins – it’s alloyed with copper and is sandwiched between layers of pure aluminum to prevent corrosion. It also should not be welded.

Aircraft Grade Aluminum Sheet packaged

The aluminum plate is paperclip or laminated to ensure that the surface of the aluminum plate is intact and free of scratches;

Plastic film ( HDPE, PVC, PE or PET etc ) protection or hard kraft paper wrapping is used to prevent moisture and rain to ensure that the aluminum plate is clean and free of dirt during transportation (each package has a moisture-proof desiccant to ensure the quality of our products in East China and South China, where there is more rain);

Packaging and shipping

Installed with wooden brackets and reinforced with steel straps to avoid collision during transportation and to ensure the geometry of the aluminum plate remains unchanged;

For export products, we use wooden boxes and pallets with fumigation mark for packaging;

We can also pack according to other packaging requirements of customers;

040 Aluminum Sheet is a type of aluminum sheet that has a thickness of 0.04 inches, which is equivalent to 1.016 millimeters. It is a thin and lightweight material

3003 h14 aluminum coil refers to h14 tempered 3003 aluminum coil.And H14 tempering usually means getting 1/2 the strength with the hardness.

Electronic aluminum foil is a kind of aluminum foil processed by a series of rolling, cleaning and cutting processes of high-purity aluminum ingots. It is a key raw material for the production of aluminum electrolytic capacitors.

Thin aluminum sheet typically refers to a flat piece of aluminum material that has a thickness of less than 6mm (0.24 inches).

In general, aluminum sheet that is thicker than 6mm (0.25 inches) is considered to be thick.

5454 aluminum circles have all the properties of 5454 aluminum alloy and are often used in can sealing, non-stick pot bottoms, traffic signs, lampshades, etc.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

Hello, I am interested in 3*1500*3500 mm 5754 H111 Checkered Aluminium Plate - Diamond Shape Powermaster Ltd. Moscow, Volokolamskoe shosse 1, str. 1, of. 19, Moscow, 125080

Buenos días, Me interesaría saber el costo de Paneles de nido de abeja de aluminio para usar como refuerzo interior de bandejas, estantes , mesadas que realizamos en acero inoxidable AISI 304. De espesor del panel de 10 y 20 mm, con la piel superior e inferior de aluminio espesor 0.8 mm liso o cepillado o solo el núcleo del nido de abeja de aluminio; con tamaño de celda de 10 o 15 mm ( o estándar ) . tamaño de las planchas de 1500 x 3000 mm o la lo que recomiende para el uso que le quiero dar. Desde ya muchas gracias

Proszę o ofertę na blachę aluminiową grubość 20 mm, w gatunku 1060. 8000 kg

Dear Sirs, I'm looking for a provider of aluminum 7075-T651 in 1.0 or 1.5 mm thickness. We need about 180 plates of 200 mm x 200 mm. Are you able to provide a quote and delivery time for this? Thank you so much in advance. Kind regards, Francisco Silva

Hello, I hope this message meets you well. I have perused your website and I want a detailed price quote for your product; upon your response to this message I will forward more details concerning this order/project to you. I look forward to doing business with you. Warm thanks. Best regards, Ahmet Emir Purchase Manager SER MEKATRONIK SANAYI VE TICARET LTD.STI. Turkgucu O.S.B. Mahallesi 216.Sokak NO:5/1 Corlu / Tekirdag / Turkey Email: [email protected]