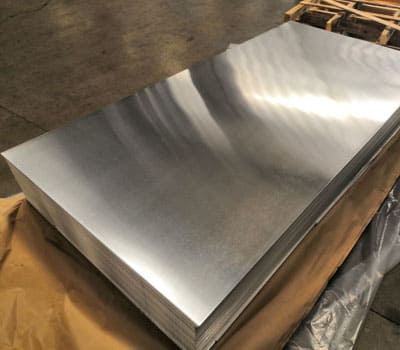

Thin aluminum sheet typically refers to a flat piece of aluminum material that has a thickness of less than 6mm (0.24 inches).

Thin aluminum sheet typically refers to a flat piece of aluminum material that has a thickness of less than 6mm (0.24 inches).

The exact thickness considered “thin” may vary depending on the specific context, but generally, thin aluminum sheet is thinner than standard aluminum plate, which can be several times thicker.

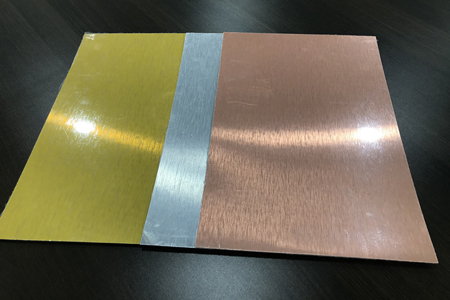

Thin aluminum sheet thickness measurement

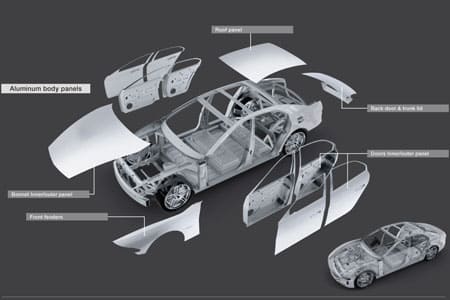

Thin aluminum sheets are commonly used in a variety of applications, including as a lightweight building material, for packaging, in the automotive industry, and for electrical and electronic components.

Aluminum sheet and aluminum plate are both flat, rectangular pieces of aluminum, but they differ in their thickness and intended use.

Aluminum sheet is typically thinner than aluminum plate, with thicknesses ranging from 0.2mm to 6mm. It is often used for lightweight applications where weight is a critical factor, such as in the construction of airplanes, cars, and electronic devices. Aluminum sheet is also commonly used in packaging and for signs and displays.

Aluminum plate, on the other hand, is thicker than aluminum sheet, with thicknesses typically ranging from 6mm to 250mm. Aluminum plate is used in a wide range of applications where strength and durability are important, such as in the construction of heavy machinery, marine equipment, and structural components for buildings and bridges.

In general, the main difference between aluminum sheet and aluminum plate is their thickness and intended use, with aluminum sheet being thinner and more suited for lightweight applications, while aluminum plate is thicker and better suited for heavy-duty applications.

The thickness of a thin aluminum sheet typically ranges from 0.2 mm (0.008 inches) to 6 mm (0.24 inches). However, the most common thicknesses of thin aluminum sheets are:

The specific thickness used in a particular application will depend on factors such as the intended use, required strength and durability, and cost.

| 7 gauge aluminum | 8 gauge aluminum | 9 gauge aluminum |

| 10 gauge aluminum | 11 gauge aluminum | 12 gauge aluminum |

| 14 gauge aluminum | 16 gauge aluminum | 18 gauge aluminum |

| 20 gauge aluminum | 22 gauge aluminum | 24 gauge aluminum |

| 26 gauge aluminum | 28 gauge aluminum | 30 gauge aluminum |

| Gauge | Inches | MM |

| 7 | .1443 | 3.665 |

| 8 | .1285 | 3.264 |

| 9 | .1144 | 2.906 |

| 10 | .1019 | 2.588 |

| 11 | .09074 | 2.305 |

| 12 | .08081 | 2.053 |

| 14 | .06408 | 1.628 |

| 16 | .05082 | 1.291 |

| 18 | .04030 | 1.024 |

| 20 | .03196 | .812 |

| 22 | .02535 | .644 |

| 24 | .02010 | .511 |

| 26 | .01594 | .405 |

| 28 | .01264 | .321 |

| 30 | .01003 | .255 |

Aluminum is classified into different series based on its alloying elements. Each series has different properties and characteristics that make it suitable for various applications. The following are the most common series of thin aluminium sheets:

These sheets contain 99% or more aluminum and have excellent corrosion resistance, high thermal and electrical conductivity. These sheets are commonly used for chemical and food processing equipment, reflectors, and decorative parts.

These sheets are aluminum-manganese alloys that have good strength and corrosion resistance. They are commonly used in the construction of boat hulls, kitchen equipment, and chemical tanks.

These sheets are aluminum-magnesium alloys that have high strength and excellent corrosion resistance. They are commonly used in the construction of marine and transportation equipment, as well as in the aerospace industry.

These sheets are aluminum-magnesium-silicon alloys that have good formability, weldability, and corrosion resistance. They are commonly used in the construction of structural components, such as railings, bridges, and buildings.

7xxx: These sheets are aluminum-zinc-magnesium alloys that have high strength and excellent fatigue resistance. They are commonly used in the construction of aircraft and aerospace components.

These sheets are aluminum-lithium alloys that have the highest strength-to-weight ratio of all aluminum alloys. They are commonly used in the aerospace industry, where weight reduction is critical.

The specific series used in a particular application will depend on factors such as required strength, corrosion resistance, formability, and cost.

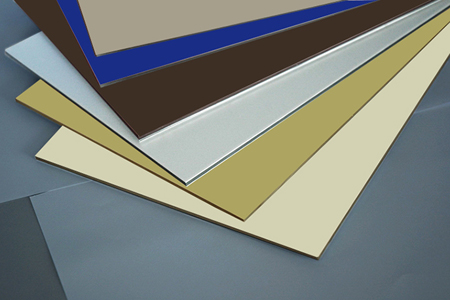

Thin aluminum sheets can undergo various surface treatment processes to improve their properties and appearance. Some of the most common surface treatment processes for thin aluminium sheets include:

|

Anodizing: This process involves immersing the aluminum sheet in an electrolytic solution and applying an electrical current. This creates a layer of oxide on the surface of the sheet, which improves its corrosion resistance and provides a decorative finish. |

|

Power coating: This process involves treating the surface of the aluminum sheet with a chemical solution to create a thin, protective layer. This layer improves the corrosion resistance and paint adhesion of the sheet. |

|

Painting: Thin aluminum sheets can be painted to provide a decorative finish and to protect the surface from corrosion and weathering. The sheet can be pre-treated with a conversion coating or primer before painting. |

|

Brushing: This process involves brushing the surface of the aluminum sheet with a wire brush to create a textured finish. This provides a decorative finish and can also hide scratches and other surface imperfections. |

|

Polishing: This process involves polishing the surface of the aluminum sheet with a polishing compound to create a high-gloss finish. This is often used in decorative applications. |

|

Laminating: Thin aluminum sheets can be laminated with a protective film to provide additional protection from corrosion and damage. |

The weight of a thin aluminum sheet can be calculated using the following formula:

Weight (in pounds) = Thickness (in inches) x Width (in inches) x Length (in inches) x Density (in lbs/in³)

The density of aluminum is typically 0.098 pounds per cubic inch.

For example, let’s say we have a thin aluminum sheet that is 0.125 inches(1/8 inchs) thick, 48 inches wide, and 96 inches long. The weight of this sheet can be calculated as:

Weight = 0.125 inches x 48 inches x 96 inches x 0.098 lbs/in³

Weight = 6 pounds

Therefore, the weight of this thin aluminium sheet is 6 pounds. Keep in mind that this is an estimate and the actual weight may vary slightly based on the specific alloy and manufacturing process used for the sheet.

The choice of thin aluminum sheet thickness depends on the specific application and the requirements for the sheet. Here are some factors to consider when choosing a thin aluminum sheet of different thickness:

Strength: The required strength of the aluminum sheet will determine the thickness needed. Thicker sheets generally have greater strength and are suitable for applications that require higher load-bearing capacity.

Flexibility: Thinner aluminum sheets are more flexible and easier to bend and shape than thicker sheets. Thinner sheets are suitable for applications where flexibility and formability are important.

Weight: Thinner aluminum sheets are lighter in weight than thicker sheets, making them suitable for applications where weight is a concern.

Corrosion resistance: The thickness of the aluminum sheet can affect its corrosion resistance. Thicker sheets are generally more resistant to corrosion and are suitable for applications in harsh environments.

Cost: The cost of the aluminum sheet is often related to its thickness. Thicker sheets are typically more expensive than thinner sheets.

Manufacturing process: The manufacturing process used to produce the aluminum sheet may also affect the available thicknesses. Some manufacturing processes are better suited for producing thinner sheets, while others are better for thicker sheets.

In summary, the choice of thin aluminum sheet thickness will depend on the specific requirements of the application, including strength, flexibility, weight, corrosion resistance, cost, and manufacturing process.

Thin aluminum sheets have a wide range of applications due to their excellent properties such as lightweight, corrosion resistance, formability, and conductivity. Some of the core applications of thin aluminium sheets are:

| Packaging: Thin aluminum sheets are commonly used in the food and beverage packaging industry due to their ability to protect the product from moisture, light, and oxygen. They are commonly used for making foil containers, trays, and wraps. |  |

| Electronics: Thin aluminum sheets are widely used in the electronics industry due to their excellent electrical conductivity and thermal properties. They are commonly used for making heat sinks, circuit boards, and casings for electronic devices. |  |

| Construction: Thin aluminum sheets are used in the construction industry for various applications such as roofing, cladding, and decorative panels. They are popular due to their lightweight, durability, and corrosion resistance. |  |

| Automotive: Thin aluminum sheets are used in the automotive industry for making body panels, engine components, and heat shields. They are preferred over steel due to their lightweight and corrosion resistance. |  |

| Aerospace: Thin aluminum sheets are widely used in the aerospace industry due to their lightweight, strength, and resistance to extreme temperatures. They are commonly used for making aircraft wings, fuselage, and structural components. |  |

| Art and decoration: Thin aluminum sheets are also used for decorative purposes such as wall art, sculptures, and jewelry due to their ability to be easily shaped and colored. |  |

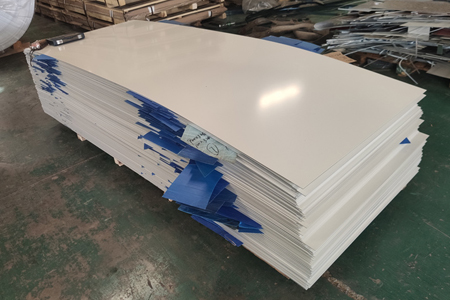

Thin aluminum sheets are typically packaged in a way that protects them from damage during transportation and storage. The packaging used for thin aluminium sheets depends on the size, shape, and quantity of the sheets. Here are some common packaging methods for thin aluminum sheets:

Pallets: Thin aluminum sheets are often stacked on pallets for easy handling and transportation. The sheets are usually secured to the pallet using straps or shrink wrap.

Cardboard boxes: Thin aluminum sheets are sometimes packaged in cardboard boxes for protection during transportation and storage. The sheets are often separated by a layer of protective material such as paper or foam to prevent them from rubbing against each other and getting scratched.

Rolls: Thin aluminum sheets can also be rolled up and packaged in a roll for easy handling and transportation. The rolls are usually wrapped in protective material such as paper or plastic to prevent them from getting scratched or damaged.

Crates: Thin aluminum sheets are sometimes packaged in wooden crates for extra protection during transportation. The crates are often lined with protective material such as foam or cardboard to prevent the sheets from rubbing against each other.

Thin aluminum sheet thickness measurement

In addition to these packaging methods, thin aluminum sheets are often labeled with important information such as the alloy type, temper, and thickness to help identify them and ensure they are used correctly. It is important to handle and store thin aluminum sheets carefully to prevent damage and ensure their quality is maintained.

The price of thin aluminum sheets depends on several factors, including the thickness, alloy, and market demand. Here are some of the key factors that affect the price of thin aluminium sheets:

Thickness: Thinner sheets are generally less expensive than thicker sheets because they require less material and less processing time.

Alloy: Different aluminum alloys have different prices based on their availability, processing costs, and market demand. For example, high-performance alloys such as 7075 or 2024 are more expensive than standard alloys like 6061.

Market demand: The price of thin aluminum sheets can fluctuate based on supply and demand in the market. If demand is high and supply is low, the price will typically increase.

Quantity: The price of thin aluminum sheets is often lower when purchased in bulk or large quantities.

Processing: Additional processing, such as surface treatment or fabrication, can increase the cost of thin aluminum sheets.

To calculate the price of thin aluminum sheets, you will need to consider these factors and obtain a quote from a supplier or manufacturer. The price is typically quoted per unit of weight, such as per pound or per kilogram. It is important to compare prices from multiple suppliers to ensure you are getting a fair price and to factor in any additional costs, such as shipping or handling fees.

Huawei Aluminum supplies a large number of 0.2-6mm thin aluminum sheets, excellent quality, low price, and excellent service. Choosing Huawei will be your most correct choice

Our embossed aluminum foil products are exported to more than 60 countries and regions in the European Union, the Middle East, Southeast Asia, and South America, and enjoy a good reputation in the international market with the best service and high-quality products.

1100 Aluminum Coil is the alloy with the highest commercial purity of all aluminum grades, with an aluminum content (mass fraction) of 99.00%. Its strength is relatively low, and it has excellent ductility, formability, weldability, and corrosion resistance.

4x8 aluminum sheet is a common size of aluminum sheet, also known as standard size aluminum sheet, referred to as standard sheet.

3003 curtain wall aluminum sheet is the outer wall of a building. It is a lightweight wall of large high-rise buildings and has a certain decorative effect.

Cold rolled aluminum strip is a thin strip made of aluminum alloy that is processed by cold rolling. It is widely used in aerospace, automobile manufacturing, building materials and other fields.

6082 aluminum sheet can be heat treated, strengthened and has good formability, weldability and machinability, also known as structural alloy.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

Proszę o ofertę na blachę aluminiową grubość 20 mm, w gatunku 1060. 8000 kg

Dear Sirs, I'm looking for a provider of aluminum 7075-T651 in 1.0 or 1.5 mm thickness. We need about 180 plates of 200 mm x 200 mm. Are you able to provide a quote and delivery time for this? Thank you so much in advance. Kind regards, Francisco Silva

Hello, I hope this message meets you well. I have perused your website and I want a detailed price quote for your product; upon your response to this message I will forward more details concerning this order/project to you. I look forward to doing business with you. Warm thanks. Best regards, Ahmet Emir Purchase Manager SER MEKATRONIK SANAYI VE TICARET LTD.STI. Turkgucu O.S.B. Mahallesi 216.Sokak NO:5/1 Corlu / Tekirdag / Turkey Email: [email protected]

I need a quotation for 3000 series aluminum sheets/coils (3104 H19) for tuna can production, food-grade finish, delivery to Mazatlán, Mexico.

I am planning a business trip to China and I am very interested in your aluminium 8011 products for food container production. I would like to visit your factory during my stay in china: See your production lines (foil rolling, annealing, slitting, packing). Discuss specifications (8011-O temper, thickness 0.05–0.08 mm, jumbo roll). Review your quality certificates and export experience. Could you please let me know: Your available dates for a visit The location of your factory If you can provide an invitation letter for my business visa (M visa). Thank you for your kind support. Looking forward to your reply. Best regard: LOUNIS MUSTAPHA company name:TOP BARQUETTE SELECT [email protected] what's up:213 770 91 69 43