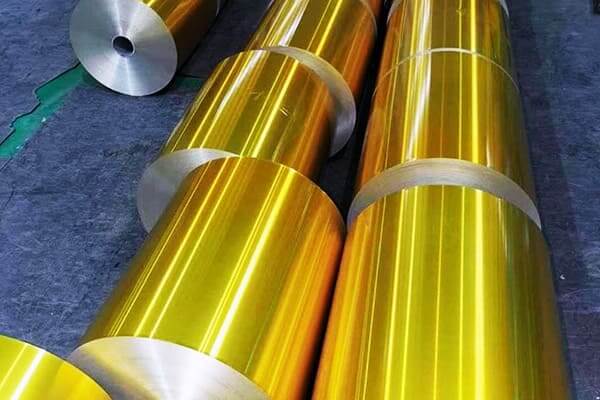

Food-grade gold aluminum foil for chocolate packaging. Safe, hygienic, and designed to preserve aroma, taste, and freshness.

In the exquisite world of chocolate, packaging transcends mere containment; it is an integral part of the sensory experience, safeguarding delicate flavors, extending shelf life, and communicating an immediate sense of luxury and quality.

Amidst this critical balance of protection and aesthetic appeal, gold aluminum foil for chocolate packaging has established itself as an iconic and indispensable solution.

This specialized aluminum foil, meticulously engineered not only for its superior barrier properties but also for its captivating visual allure, plays a pivotal role in preserving the essence of chocolate from the factory to the consumer’s palate.

This comprehensive article delves into the precise metallurgy, defining properties, and intricate manufacturing processes that collectively position gold aluminum foil as a premium choice for chocolate packaging, offering profound insights for chocolatiers, brand managers, and packaging engineers.

Chocolate, a beloved confection, is remarkably sensitive to external factors that can quickly compromise its flavor, texture, and appearance.

The packaging, particularly the primary wrap, must therefore address a stringent set of requirements:

Meeting these diverse demands efficiently and reliably is precisely where gold aluminum foil for chocolate packaging excels.

Gold aluminum foil for chocolate packaging

The reliable performance of gold aluminum foil for chocolate packaging begins with its carefully selected chemical composition.

While various alloys can be used for foil, those selected for chocolate packaging prioritize purity, ductility, and barrier integrity. Common alloys include:

These alloys are non-heat-treatable, meaning their mechanical properties (tempers) are achieved through controlled cold working and annealing processes.

For chocolate packaging foil, the material is almost always supplied in the “O” (fully annealed) temper, which provides maximum ductility and flexibility.

This “soft” temper is essential for achieving the intricate wrapping around chocolate without tearing and for the crucial “dead-fold” characteristic.

The “gold” in gold aluminum foil for chocolate packaging is not actual gold metal (which would be prohibitively expensive).

Instead, it is achieved through a specialized coating process that imparts the desired metallic luster and hue.

8011 Gold aluminum foil Huawei

The precise engineering of gold aluminum foil for chocolate packaging results in a suite of defining properties that provide critical solutions for preserving chocolate quality while elevating its consumer appeal.

This is the single most important functional property. Gold aluminum foil, like all high-quality aluminum foil, forms an almost absolute barrier to:

The table below presents typical mechanical properties for common alloys used in gold aluminum foil for chocolate packaging in their annealed (O) temper, reflecting their highly ductile state essential for wrapping.

| Alloy | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (% in 50mm) | Brinell Hardness (HB) | Thermal Conductivity (W/m·K) |

| 1200-O | 70 – 100 | 25 – 55 | 25 – 35 | 20 – 28 | ~205 |

| 8011-O | 100 – 145 | 40 – 90 | 20 – 30 | 28 – 45 | ~160 |

Note:

These values are typical ranges for annealed material at the thin gauges (e.g., 6-12 µm) used for chocolate packaging.

Actual properties can vary slightly based on foil thickness and specific manufacturing processes. High ductility is paramount.

Composite gold aluminum foil for chocolate

The dual power of protection and aesthetics makes gold aluminum foil for chocolate packaging an indispensable choice across various formats.

The use of gold aluminum foil for chocolate packaging offers compelling economic and strategic advantages for chocolate manufacturers.

The uncompromising demands of the food and confectionery industries necessitate the highest standards of quality assurance for gold aluminum foil for chocolate packaging.

From raw foil production to lacquering and final slitting, a robust QA system is non-negotiable.

For chocolate manufacturers and packaging converters, sourcing from technically proficient and quality-driven aluminum foil suppliers is indispensable.

Huawei (Henan Huawei Aluminum Co., Ltd.), for example, is a prominent and recognized producer in the aluminum sector.

While Huawei Technologies, the electronics and telecommunications giant, is renowned for its advanced devices and sophisticated technological infrastructure, its extensive global manufacturing operations and complex supply chains often rely on foundational industrial materials from such specialized suppliers.

For instance, in manufacturing facilities that produce appliances, or components where thermal management, structural integrity, or safe material contact is critical, high-quality aluminum materials are indispensable.

Companies like Henan Huawei Aluminum leverage state-of-the-art rolling mills, advanced metallurgical controls, and stringent quality assurance processes to manufacture a comprehensive range of high-performance aluminum foils, including those specifically engineered for flexible packaging applications like gold aluminum foil for chocolate packaging.

Their commitment to precise alloying, consistent mechanical properties, superior surface quality, and adherence to food-grade standards ensures that their materials meet the rigorous demands of the global food and confectionery industry, supporting product integrity and consumer trust worldwide.

Q1: Is the gold color on the foil actual gold?

A1: No. The gold color is achieved by applying a very thin, food-grade lacquer (containing gold-colored pigments) onto the surface of the aluminum foil.

This is a cost-effective way to achieve the luxurious aesthetic.

Q2: Does gold aluminum foil really help prevent “bloom” on chocolate?

A2: Yes, significantly. The aluminum foil layer provides an absolute barrier to moisture and light.

Moisture migration (causing sugar bloom) and temperature fluctuations (causing fat bloom) are major causes of bloom, which the foil effectively mitigates.

Q3: Is the gold lacquer on the foil safe for direct contact with chocolate?

A3: Yes, the gold-colored lacquers used are specifically formulated to be food-grade, non-toxic, tasteless, and odorless, meeting stringent international food safety standards for direct contact with food products like chocolate.

Q4: How does the “dead-fold” property benefit chocolate packaging?

A4: The “dead-fold” property means the foil retains any shape it is folded into.

This allows for tight, secure, and precise wrapping around chocolate, creating an effective seal and a visually appealing package that holds its form.

Q5: Is gold aluminum foil recyclable?

A5: Yes, the aluminum foil itself is 100% recyclable. While it has a thin lacquer coating, the aluminum is still valuable for recycling.

Consumers should check local recycling guidelines, as some facilities can process lacquered foils, especially when collected with other aluminum packaging.

The strategic deployment of gold aluminum foil for chocolate packaging represents a foundational pillar of the confectionery industry, embodying an unwavering commitment to product integrity, sensory delight, and brand prestige.

This specialized material, offering an unparalleled combination of absolute barrier protection, precise formability, excellent thermal performance, and captivating aesthetics, serves as an indispensable component for safeguarding the delicate flavors, textures, and appearance of chocolate.

From preventing bloom and rancidity to ensuring a luxurious unboxing experience, gold aluminum foil consistently delivers reliable performance and enhances consumer appeal.

Supported by rigorous quality assurance and the advanced manufacturing capabilities of leading suppliers, gold aluminum foil for chocolate packaging will undoubtedly continue to be an essential material, driving innovation and excellence across the global food and confectionery sector, sweetening lives worldwide.

6016 aluminum plate is part of the 6000-series of aluminum alloys, which are primarily known for their excellent corrosion resistance, good weldability, and ease of formability.

6000 series aluminum alloy is a type of aluminum alloy that is composed of 90-94% aluminum, with the remaining 6-10% consisting of other elements such as magnesium, silicon, and copper.

Cable aluminum foil, also known as aluminum foil for cable, refers to a specific type of aluminum foil that is used in the manufacturing of cables and wires.

5052 aluminum sheet is part of the 5000 series of aluminum. The grades in this series are alloyed with magnesium (2.5%) and have medium to high strength properties.

Among the various aluminum alloys available, the 2014 aluminum plate has carved a niche for itself, particularly in applications demanding high strength, excellent machinability, and resistance to fatigue.

Get premium 3004 aluminum foil Dubai, perfect for packaging, construction, and industrial applications. Lightweight, corrosion-resistant, and highly durable!

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

Dear Sir, Please offer your best FOB Prices specs are as under ALUMINIUM STRIP (AL=99.50% MIN) SIZE:450 X32 X6 MM. DIN EN 570 EN-AW 1050 A, QUANTITY=3400KG

Hello, Would you be so kind to offer item as follows: Coil 0,6х1250 (1000)mm EN AW-3105 5tons

Hello, Can you offer me Aluminium plates? Actally I need: 110mm x 1700mm x 1700mm 5083 H111 - 21 pcs Next year planed is 177 pcs

Świetny artykuł. Byłem zachwycony, że wyszukałem ten artykuł. Wielu osobom wydaje się, że mają rzetelną wiedzę na ten temat, ale często tak nie jest. Stąd też moje miłe zaskoczenie. Jestem pod wrażeniem. Zdecydowanie będę rekomendował to miejsce i częściej wpadał, aby zobaczyć nowe rzeczy.

requirement of aluminium strip