Among the various aluminum alloys available, the 2014 aluminum plate has carved a niche for itself, particularly in applications demanding high strength, excellent machinability, and resistance to fatigue.

In the realm of industrial materials, aluminum stands out for its versatility, strength, and lightweight properties. Among the various aluminum alloys available, the 2014 aluminum plate has carved a niche for itself, particularly in applications demanding high strength, excellent machinability, and resistance to fatigue. This article delves into the specifics of the 2014 aluminum plate, exploring its composition, properties, applications, and why it’s a preferred choice in critical sectors like aerospace, automotive, and heavy machinery manufacturing.

2014 Aluminum Plate Sheet

The 2014 aluminum alloy’s chemical composition is detailed in the table below:

| Element | Percentage (%) |

| Aluminum (Al) | Base Metal |

| Copper (Cu) | 3.9 – 5.0 |

| Silicon (Si) | 0.5 – 1.2 |

| Iron (Fe) | ≤ 0.7 |

| Manganese (Mn) | 0.4 – 1.2 |

| Magnesium (Mg) | 0.2 – 0.8 |

| Chromium (Cr) | ≤ 0.1 |

| Zinc (Zn) | ≤ 0.25 |

| Titanium (Ti) | ≤ 0.15 |

The 2014 aluminum alloy can be heat-treated to achieve different temper conditions, each offering distinct mechanical properties:

Here is a comparison of the mechanical properties of 2014 aluminum plate under different temper conditions:

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) |

| T3 | 425-460 | 290-330 | 12-15 | 105-130 |

| T4 | 400-440 | 270-310 | 14-17 | 95-120 |

| T6 | 450-495 | 350-390 | 10-13 | 120-140 |

| T7 | 390-430 | 250-290 | 15-18 | 110-130 |

As a high-strength aluminum alloy, the 2014 aluminum sheet possesses the following noteworthy features:

Bulefilm 2014 Aluminum Sheet

Superior Strength and Fatigue Resistance

The high copper content in 2014 aluminum significantly boosts its strength, making it suitable for structural components that must withstand high stress. Its fatigue resistance is also noteworthy, which is crucial for applications where parts are subject to cyclic loading.

Excellent Machinability

One of the standout features of 2014 aluminum is its excellent machinability. This attribute allows for intricate designs and precise manufacturing, reducing tool wear and production costs, which is highly beneficial for custom parts and prototypes.

Aerospace

Automotive

Industrial Machinery

Applications of 2014 Aluminum Plate

| Alloy | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Fatigue Strength (MPa) |

| 2014 | 425-495 | 290-360 | 10-13 | 130 |

| 2024 | 425-470 | 290-350 | 12-17 | 130-140 |

| 7075 | 510-570 | 430-505 | 5-11 | 160 |

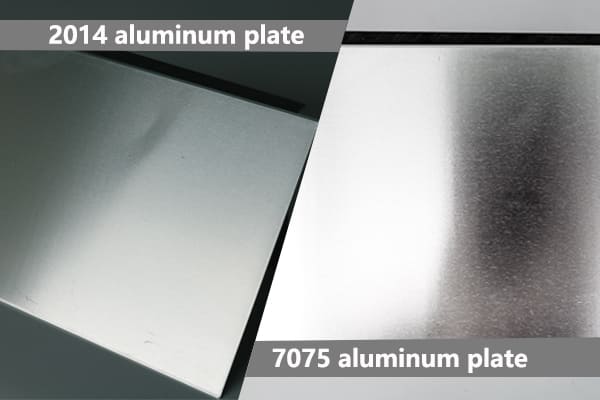

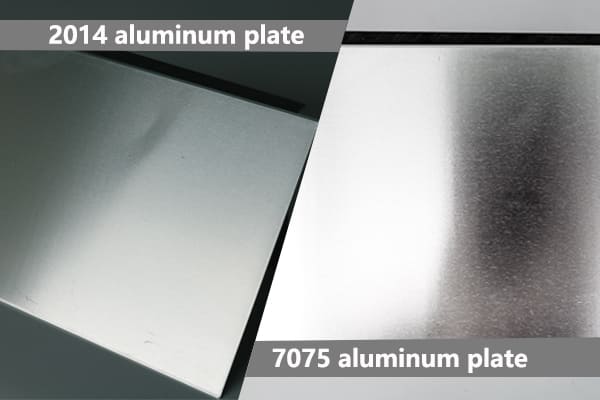

Advantages Over Other Alloys

Limitations

What are the advantages of 2014 aluminum plate compared to other aluminum alloys?

In comparison to common alloys such as 1050 and 6061, the paramount strength of 2014 aluminum plate lies in its exceptional tensile strength and superior mechanical properties, particularly well-suited for applications requiring high strength and durability.

How is the weldability of 2014 aluminum sheet?

The weldability of 2014 aluminum sheet is notable, albeit requiring special attention during welding due to its higher copper content, ensuring quality weld joints and monitoring the subsequent changes in strength post heat treatment.

How can the surface quality of 2014 aluminum plate be guaranteed?

The surface of 2014 aluminum plate can be enhanced through treatments such as anodizing, spraying, coatings, etc., thereby improving its corrosion resistance and aesthetic appeal.

What is the pricing of 2014 aluminum sheet?

Given its high strength and elevated copper content, the price of 2014 aluminum sheet typically surpasses that of conventional aluminum alloys. However, in advanced sectors like aerospace and aviation, its exceptional performance warrants a commendable cost-effectiveness.

The 2014 aluminum plate offers a unique combination of strength, machinability, and fatigue resistance, making it an invaluable material in industries where performance under stress is paramount. Its ability to be heat-treated to further enhance its properties adds to its appeal for critical applications. While it requires careful handling regarding corrosion, with the right treatments and applications, 2014 aluminum continues to be a material of choice for engineers and designers worldwide, pushing the boundaries of what’s possible in modern manufacturing and aerospace technology.

Huawei Aluminum is a high-quality 8079 aluminum foil manufacturer. It has multiple advantages in the production of 8079 aluminum foil. Its aluminum foil products are deeply loved by customers at home and abroad.

3004 aluminum coil is an aluminum-manganese alloy, which is the most widely used anti-rust aluminum. The strength of this alloy is not high. It is similar to 3003 alloys with about 1% magnesium added.

High-adhesion, corrosion-resistant 8011 gold hydrophilic aluminum foil for sealing, lamination, and HVAC applications.

6061 aluminum sheet is an al-si-mg alloy that has been strengthened by precipitation hardening. 6061 aluminum has a high strength-to-weight ratio, above-average corrosion resistance, good machinability, and is well suited for welding.

5454-O aluminium circle represents 5454 aluminum alloy O temper aluminum circle, belongs to 5000 series aluminum alloy.

5454 aluminum circles have all the properties of 5454 aluminum alloy and are often used in can sealing, non-stick pot bottoms, traffic signs, lampshades, etc.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

2000x3000mm aluminum sheet Price and transport

Our required qty: Aluminium Sheet in coil (620mm X 1.20mm) Qty: 200 MT. Can you give me the number of contact urgently. Thanks Matiur Rahman Director of Technical Sales dept.

Bonjour ; Nous sommes une compagnie de spectacle de rue " compagnie carabosse " nous travaillons avec la flamme . nous sommes à la recherche de tôle reflecteur en aluminium pour pouvoir crée un nouvelle objet à base d'un fil métal enflammé liquide éthanol d' une hauteur environ 1 m . Quels produits avez vous à nous proposez ? Cordialement Fabrice

Hello, I am interested in 3*1500*3500 mm 5754 H111 Checkered Aluminium Plate - Diamond Shape Powermaster Ltd. Moscow, Volokolamskoe shosse 1, str. 1, of. 19, Moscow, 125080

Buenos días, Me interesaría saber el costo de Paneles de nido de abeja de aluminio para usar como refuerzo interior de bandejas, estantes , mesadas que realizamos en acero inoxidable AISI 304. De espesor del panel de 10 y 20 mm, con la piel superior e inferior de aluminio espesor 0.8 mm liso o cepillado o solo el núcleo del nido de abeja de aluminio; con tamaño de celda de 10 o 15 mm ( o estándar ) . tamaño de las planchas de 1500 x 3000 mm o la lo que recomiende para el uso que le quiero dar. Desde ya muchas gracias