3004 aluminum coil is an aluminum-manganese alloy, which is the most widely used anti-rust aluminum. The strength of this alloy is not high. It is similar to 3003 alloys with about 1% magnesium added.

3004 aluminum coil is an aluminum-manganese alloy, which is the most widely used anti-rust aluminum. The strength of this alloy is not high. It is similar to 3003 alloys with about 1% magnesium added.

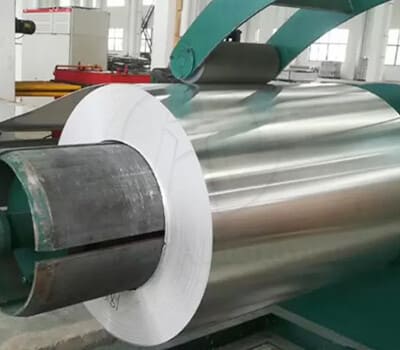

3004 aluminum coil near me

The strength of this alloy is not high (slightly higher than that of industrial pure aluminum) and cannot be strengthened by heat treatment, so a cold working method to improve its mechanical properties is used: it has high plasticity in the annealed state, good plasticity in semi-cold hardening, and plasticity in cold hardening. Low, good corrosion resistance, good weldability, good cutting performance.

It is usually rolled and extruded (used to make beverage cans), but not usually forged. As a wrought alloy, not for casting.

3004 Aluminium Coil China Supplier

3004 Aluminium Coil Inventory

| Al | Mg | Si | Fe | Cu | Zn | Mn | Remainder |

|---|---|---|---|---|---|---|---|

| 95.6 to 98.2% | 0.8 to 1.3% | 0.3% max | 0.7% max | 0.25% max | 0.25% max | 1.0 to 1.5% | 0.15% max |

From: wikipedia

Alternate designations include 3.0526 and A93004. 3004 aluminium and its various tempers are discussed in the following standards: [1]

| Temper | Specified Thickness(in) | Tensile Strength – KSI | Elongationin 2 inches % | |||

| Ultimate | Yield | |||||

| Min | Max | Min | Max | |||

| H12 | 0.008 – 0.020 | 27.6 | 34.8 | – | – | 2 |

| 0.020 – 0.059 | 3 | |||||

| 0.059 – 0.118 | 4 | |||||

| 0.118 – 0.236 | 5 | |||||

| 0.236 – 0.394 | – | |||||

| H14 | 0.008 – 0.020 | 31.9 | 38.4 | – | – | 1 |

| 0.020 – 0.059 | 2 | |||||

| 0.059 – 0.118 | 2 | |||||

| 0.118 – 0.250 | 3 | |||||

| H16 | 0.008 – 0.020 | 34.8 | 41.3 | – | – | 1 |

| 0.020 – 0.059 | 1 | |||||

| 0.059 – 0.118 | 2 | |||||

| 0.118 – 0.250 | 2 | |||||

| H18 | 0.008 – 0.020 | 37.7 | – | – | – | 1 |

| 0.020 – 0.059 | 1 | |||||

| 0.059 – 0.118 | – | |||||

| 0.118 – 0.250 | – | |||||

| H19 | 0.008 – 0.020 | 39.2 | – | – | – | 1 |

| 0.020 – 0.059 | 1 | |||||

| 0.059 – 0.118 | – | |||||

| 0.118 – 0.250 | – | |||||

| H22/32 | 0.008 – 0.020 | 27.6 | 34.8 | – | – | 4 |

| 0.020 – 0.059 | 5 | |||||

| 0.059 – 0.118 | 6 | |||||

| 0.118 – 0.250 | 7 | |||||

| 0.236 – 0.394 | – | |||||

| H24/34 | 0.008 – 0.020 | 31.9 | 38.4 | – | – | 3 |

| 0.020 – 0.059 | 4 | |||||

| 0.059 – 0.118 | 4 | |||||

| 0.118 – 0.250 | – | |||||

| H26/36 | 0.008 – 0.020 | 34.8 | 41.3 | – | – | 3 |

| 0.020 – 0.059 | 3 | |||||

| 0.059 – 0.118 | 3 | |||||

| 0.118 – 0.250 | – | |||||

| H28/38 | 0.008 – 0.020 | 37.7 | – | 2 | ||

| 0.020 – 0.059 | 3 | |||||

| 0.059 – 0.118 | – | |||||

| 0.118 – 0.250 | – | |||||

| O/H111 | 0.008 – 0.020 | 22.5 | 29 | – | 13 | |

| 0.020 – 0.059 | 14 | |||||

| 0.059 – 0.118 | 15 | |||||

| 0.118 – 0.250 | 16 | |||||

Advantages of 3004 Aluminum Coil

Excellent punching ability and good oxidation, its surface can be anodized to improve hardness and wear resistance, at the same time it also gives a bright and colorful surface. And it has been improved on the basis of 3003 aluminum. Harder than 3003.

3004 aluminum coils are mainly used in chemical products and storage devices, building materials, cable pipes, sewers, various lamps, beverage cans, wave plates, color aluminum plates, lamp holders, etc.

Huawei Aluminum is a large-scale 5052 aluminum foil raw material manufacturer, with 30 years of experience in aluminum foil production and sales.

The 1000 Series Rolled Mirror Aluminum Plate is a high-purity aluminum product with an exceptional surface finish that provides a mirror-like appearance.

Brushed aluminum plate is a flat piece of aluminum material that has been treated with a brushing process to produce a uniform, unidirectional texture on its surface.

1050 aluminum sheet is a kind of non-heat-treated aluminum plate, which has good plasticity, corrosion resistance, electrical conductivity and thermal conductivity after cold working;

Compared with other alloy foils of series 1, such as 1060 and 1070 aluminum foils, the content of (Fe+Si) in 1100 aluminum foil is higher than both, and the content of Fe is the key factor to improve the strength and toughness

1070 Aluminum Foil stands at the intersection of performance, cost‑efficiency, and sustainability. Its unmatched purity and formability drive its dominance in packaging, electronics, and industrial applications.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

Dear Sirs, I'm looking for a provider of aluminum 7075-T651 in 1.0 or 1.5 mm thickness. We need about 180 plates of 200 mm x 200 mm. Are you able to provide a quote and delivery time for this? Thank you so much in advance. Kind regards, Francisco Silva

Hello, I hope this message meets you well. I have perused your website and I want a detailed price quote for your product; upon your response to this message I will forward more details concerning this order/project to you. I look forward to doing business with you. Warm thanks. Best regards, Ahmet Emir Purchase Manager SER MEKATRONIK SANAYI VE TICARET LTD.STI. Turkgucu O.S.B. Mahallesi 216.Sokak NO:5/1 Corlu / Tekirdag / Turkey Email: [email protected]

I need a quotation for 3000 series aluminum sheets/coils (3104 H19) for tuna can production, food-grade finish, delivery to Mazatlán, Mexico.

I am planning a business trip to China and I am very interested in your aluminium 8011 products for food container production. I would like to visit your factory during my stay in china: See your production lines (foil rolling, annealing, slitting, packing). Discuss specifications (8011-O temper, thickness 0.05–0.08 mm, jumbo roll). Review your quality certificates and export experience. Could you please let me know: Your available dates for a visit The location of your factory If you can provide an invitation letter for my business visa (M visa). Thank you for your kind support. Looking forward to your reply. Best regard: LOUNIS MUSTAPHA company name:TOP BARQUETTE SELECT [email protected] what's up:213 770 91 69 43

Merhaba ; Burak ÜNAL ben. Antalya ' da Ambalaj ve Temizlik ürünleri tedarik eden bir firmanın yetkilisiyim. Ayrıca P.E Streç aktarım işi yapmaktayım. Makinalarımızı 9 ve 10 micron alüminyum folyo aktarımına uyacak şekilde revize edeceğiz. Sizden istediğim, 9 veya 10 micron olacak şekilde 35 cm ve 45 cm jumbo folyolar için fiyat, termin ve şu bilgileri istiyorum ; 35 cm jumbo folyonun ortalama ağırlığı. 45 cm jumbo folyonun ortalama ağırlığı. Deneme olacağı için bu 2 ölçüde minimum sipariş tonajımız ne kadar olması gereklidir. İyi çalışmalar.