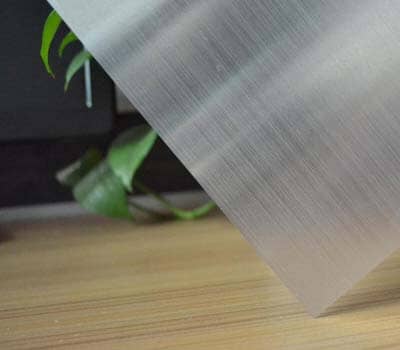

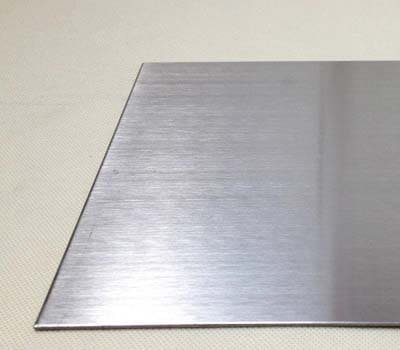

Brushed aluminum plate is a flat piece of aluminum material that has been treated with a brushing process to produce a uniform, unidirectional texture on its surface.

Brushed aluminum sheet is a flat piece of aluminum sheet that has been treated with a brushing process to produce a uniform, unidirectional texture on its surface. This texture is created by using a brush to pass over the surface of the aluminum, removing some of the material and leaving behind parallel lines or grooves. Brushed aluminum plates are commonly used for a variety of purposes, including architectural and industrial applications, due to its durability, low maintenance, and aesthetic appeal. The brushed finish can also provide additional benefits such as improved grip or reduced glare.

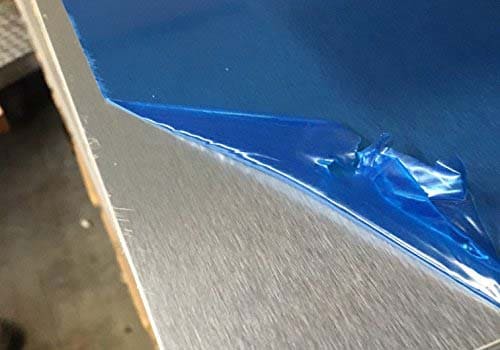

4×8 brushed aluminum sheet with blue film

Brushed aluminum sheets have several features that make them desirable for a wide range of applications:

Brushed aluminum plates have a wide range of uses due to their durability, low maintenance, and aesthetic appeal. Some of the most common uses for brushed aluminum plates include:

| Architectural applications | Brushed aluminum plates are often used in building and construction, as cladding for walls, roofs, and facades, as well as for curtain walls, column covers, and handrails. |  |

| Furniture | Brushed aluminum is used in the manufacture of furniture, such as chairs, tables, and cabinets, due to its lightweight, durability, and aesthetic appeal. |  |

| Kitchen appliances | Brushed aluminum is a popular choice for kitchen appliances, such as refrigerators, stoves, and dishwashers, due to its low maintenance, durability, and modern appearance. |  |

| Lighting fixtures | Brushed aluminum is used in the manufacture of lighting fixtures, such as pendant lights, wall sconces, and table lamps, due to its reflectivity and reduced glare. |  |

| Electronics | Brushed aluminum is used in the manufacture of electronic devices, such as laptops, smartphones, and tablet computers, due to its lightweight, durability, and thermal conductivity. |  |

| Automotive | Brushed aluminum is used in the automotive industry for body panels, wheels, and engine components, due to its strength, durability, and resistance to corrosion. |  |

| Signage | Brushed aluminum is used for signage, as it can be easily cut, bent, and shaped into a variety of shapes and sizes, and it provides a modern, clean appearance. |  |

Brushed aluminum sheets are produced through a process called brushing, which involves passing a brush over the surface of the aluminum to create a uniform, unidirectional texture. The following is a general outline of the steps involved in producing a brushed aluminum sheet:

Notes: the exact steps involved in producing a brushed aluminum sheet may vary depending on the specific process used, the equipment available, and the desired outcome. Additionally, some brushed aluminum sheets may be anodized or painted to provide additional protection and color.

Brushed aluminum has a distinct, uniform appearance that is characterized by parallel lines or grooves on its surface. The direction of the lines or grooves is typically unidirectional, running in a single direction across the entire surface of the aluminum. The lines or grooves give the aluminum a matte or satin finish that is smooth to the touch, but not as shiny as polished aluminum. The depth and spacing of the lines or grooves can vary depending on the specific brushing process used, and the overall look of the brushed aluminum can range from a subtle texture to a more pronounced, rough surface. The appearance of brushed aluminum can also be affected by factors such as lighting, angle, and the surrounding environment, which can cause it to appear lighter or darker, or to reflect more or less light.

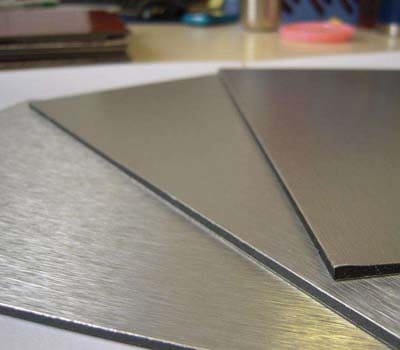

Brushed aluminum sheets that are 4 feet by 8 feet are commonly available from metal suppliers and manufacturers. These sheets are typically made from 3003 or 5052 Aluminum Sheet, which are known for their strength, durability, and resistance to corrosion. Brushed aluminum sheets in this size are often used for a variety of applications, such as architectural cladding, wall panels, and furniture. They can be easily cut, bent, and shaped into a variety of shapes and sizes to suit the needs of a specific project. The brushed finish provides a unique, modern appearance and can also help to reduce glare and improve grip in certain applications. If you are looking for brushed aluminum sheets in 4×8, it is best to check with local metal suppliers or online retailers to see what options are available in your area.

Brushed aluminum and brushed nickel are two different materials that are often used in various applications due to their unique properties and finishes. The main difference between the two is the type of metal they are made of:

brushed aluminum vs brushed nickel

In terms of appearance, brushed aluminum and brushed nickel have a similar, matte finish with uniform, unidirectional lines or grooves on their surface. However, brushed nickel is typically a brighter, shinier metal compared to brushed aluminum, which is a more muted, matte metal. Additionally, brushed nickel is more expensive than brushed aluminum due to the higher cost of nickel compared to aluminum. When choosing between brushed aluminum and brushed nickel, it is important to consider factors such as cost, durability, and appearance, as well as the specific requirements of your project.

Yes, brushed aluminum can be painted. Brushed aluminum has a porous surface, which allows paint to adhere to it. However, it is important to properly prepare the surface of the aluminum before painting to ensure that the paint adheres well and lasts for a long time. The following steps can be followed to paint brushed aluminum:

colored brushed aluminum plate

It is important to follow the instructions on the paint, primer, and other products that you use, as well as any safety precautions and guidelines, to ensure that your painting project goes smoothly and produces a long-lasting, beautiful finish.

Aluminum foil containers made of aluminum foil can be processed into various shapes, common alloys are 8011, 3003, 3004, 5052 aluminum foil.

1050 Aluminum Coil belongs to the commercially pure wrought 1000 series of alloys with a purity of 99.5% aluminum. This alloy is usually used for cold rolling or extrusion. It has the characteristics of high plasticity, corrosion resistance, electrical conductivity, and thermal conductivity.

We use the pure aluminum ingots to manufacture 5mm aluminum sheets. They come in various widths and tempers. They are not only suitable for marine grade, but also for automobile manufacturing, pressure vessels, including water tanks, oil tanks, and the maximum width we can produce is 3000mm.

4x8 aluminum sheet is a common size of aluminum sheet, also known as standard size aluminum sheet, referred to as standard sheet.

3003 curtain wall aluminum sheet is the outer wall of a building. It is a lightweight wall of large high-rise buildings and has a certain decorative effect.

3003 aluminum sheet is an alloy with very good corrosion resistance and moderate strength, the reason this metal is widely used is because it is affordable and strong.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

Dear Sir, Please offer your best FOB Prices specs are as under ALUMINIUM STRIP (AL=99.50% MIN) SIZE:450 X32 X6 MM. DIN EN 570 EN-AW 1050 A, QUANTITY=3400KG

Hello, Would you be so kind to offer item as follows: Coil 0,6х1250 (1000)mm EN AW-3105 5tons

Hello, Can you offer me Aluminium plates? Actally I need: 110mm x 1700mm x 1700mm 5083 H111 - 21 pcs Next year planed is 177 pcs

Świetny artykuł. Byłem zachwycony, że wyszukałem ten artykuł. Wielu osobom wydaje się, że mają rzetelną wiedzę na ten temat, ale często tak nie jest. Stąd też moje miłe zaskoczenie. Jestem pod wrażeniem. Zdecydowanie będę rekomendował to miejsce i częściej wpadał, aby zobaczyć nowe rzeczy.

requirement of aluminium strip