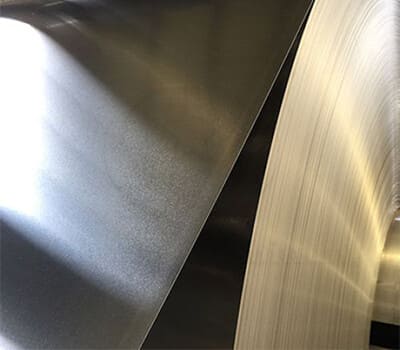

1050 Aluminum Coil belongs to the commercially pure wrought 1000 series of alloys with a purity of 99.5% aluminum. This alloy is usually used for cold rolling or extrusion. It has the characteristics of high plasticity, corrosion resistance, electrical conductivity, and thermal conductivity.

Note: Customized services such as alloy, tempering, thickness, width, packaging, etc. are available.

1050 Aluminum Coil belongs to the commercially pure wrought 1000 series of alloys with a purity of 99.5% aluminum. This alloy is usually used for cold rolling or extrusion. It has the characteristics of high plasticity, corrosion resistance, electrical conductivity, and thermal conductivity.

In addition, the 1050 aluminum alloy coil is also a non-heat-treated alloy, with low strength, cannot be strengthened by heat treatment, and has weak machinability. But it can accept contact welding and gas welding, and it is easy to withstand various pressure processing, stretching, and bending. The manufacturing process is relatively simple and the price is relatively cheap.

1050 Aluminum Coil

Alloy 1050 is a very comprehensive product for chemical and electrical applications. Huawei Aluminium Corporation has ample 1050 aluminium coil stock with reasonable prices, fast delivery, and the best service.

Common Sizes: 4×8, 8x4ft, 2000mm x 1000mm, 3000×1500, 2400×1200, 1000×2000, 2500×1250, 4×10, 5×10, 48×96 inches, 60×120 inches

Common thickness: 1mm, 2mm, 3mm, 4mm, 5mm, 6mm, 8mm, 10mm

| Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Others Each |

Total | Total Aluminum Min |

| ≤0.25 | ≤0.40 | ≤0.05 | ≤0.05 | ≤0.05 | – | – | ≤0.05 | ≤0.03 | ≤0.03 | – | 99.50 |

| Alloy | Temper | Specified thickness | Tensile strength(MPa) | Tensile strength(MPa) | Yield strength(MPa) | ||

| 1050 | H111 | >0.20 – 0.50 | >65 – 95 | >65 – 95 | 20 | 20 | ≧20 |

| >0.50 – 1.50 | 22 | ≧22 | |||||

| >1.50 – 3.00 | 26 | ≧26 | |||||

| >3.00 – 6.00 | 29 | ≧29 | |||||

| H12 | >0.20 – 0.50 | >85 – 125 | 90 – 135 | 65 | 2 | ≧2 | |

| >0.50 – 1.50 | 4 | ≧4 | |||||

| >1.50 – 3.00 | 5 | ≧5 | |||||

| >3.00 – 6.00 | 7 | ≧7 | |||||

| H22 | >0.20 – 0.50 | >85 – 125 | >85 – 125 | 55 | 4 | ≧4 | |

| >0.50 – 1.50 | 5 | ≧5 | |||||

| >1.50 – 3.00 | 6 | ≧6 | |||||

| >3.00 – 6.00 | 11 | ≧11 | |||||

| H14 | >0.20 – 0.50 | >105 – 145 | 110 – 155 | 85 | 2 | ≧2 | |

| >0.50 – 1.50 | 2 | ≧2 | |||||

| >1.50 – 3.00 | 110 – 145 | 4 | ≧4 | ||||

| >3.00 – 6.00 | 5 | ≧5 | |||||

| H24 | >0.20 – 0.50 | >105 – 145 | 115 – 155 | 75 | 3 | ≧3 | |

| >0.50 – 1.50 | 4 | ≧4 | |||||

| >1.50 – 3.00 | >105 – 145 | 110 – 145 | 75 | 5 | ≧5 | ||

| >3.00 – 6.00 | 8 | ≧8 | |||||

| H16 | >0.20 – 0.50 | >120 – 160 | 100 | 1 | ≧1 | ||

| >0.50 – 1.50 | 2 | ≧2 | |||||

| >1.50 – 4.00 | 3 | ≧3 | |||||

| H26 | >0.20 – 0.50 | >120 – 160 | 120 – 170 | 90 | 2 | ≧2 | |

| >0.50 – 1.50 | 3 | ≧3 | |||||

| >1.50 – 4.00 | 120 – 160 | 4 | ≧4 | ||||

| H18 | >0.20 – 0.50 | 135 | >135 | 120 | 1 | ≧1 | |

| >0.50 – 1.50 | 140 | >140 | 2 | ≧2 | |||

| >1.50 – 3.00 | 2 | ≧2 |

Generally, 1050 aluminium coils are often used in some working conditions that require high corrosion resistance and formability, but low strength. Among them, 1050 aluminum alloy is an industrial aluminum material, which is typically used to manufacture containers in the chemical industry.

| aluminium alloy 1050 coils | aluminium coil suppliers | 1050 aluminum coil price |

| aluminum coil sizes | aluminium coil uses | aluminium coil price in india |

| aluminium coil supplier in delhi | aluminium alloy 1050 coils stockholders | aluminium 1050 coils manufacturers |

| al alloy 1050 coil | aluminum coil price per kg | aluminum coil stock |

Aluminum circle for cookware bottoms are normally called "aluminum disc" or "aluminum disk." these are circular portions of aluminum which might be used because the base or backside of various forms of cookware, which includes pots, pans, and strain cookers.

8021 aluminium foil is a common alloy in 8000 series aluminum alloys. Common aluminum foils in 8000 series aluminum alloys include 8011 Aluminum Foil and 8079.

Upgrade your roof with high-quality aluminum roofing sheets. Experience long-lasting protection and enhance your home's aesthetics with our stylish and durable roofing solution

5086 aluminum sheet is a high-strength, corrosion-resistant al-mg alloy, widely used in aerospace, transportation, architectural decoration and other fields.

1050 aluminum sheet is a kind of non-heat-treated aluminum plate, which has good plasticity, corrosion resistance, electrical conductivity and thermal conductivity after cold working;

Diamond aluminum sheet is a type of aluminum sheet that features a raised diamond pattern on one side, which provides excellent slip resistance and traction in wet and slippery conditions.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

Dear Sir, Please offer your best FOB Prices specs are as under ALUMINIUM STRIP (AL=99.50% MIN) SIZE:450 X32 X6 MM. DIN EN 570 EN-AW 1050 A, QUANTITY=3400KG

Hello, Would you be so kind to offer item as follows: Coil 0,6х1250 (1000)mm EN AW-3105 5tons

Hello, Can you offer me Aluminium plates? Actally I need: 110mm x 1700mm x 1700mm 5083 H111 - 21 pcs Next year planed is 177 pcs

Świetny artykuł. Byłem zachwycony, że wyszukałem ten artykuł. Wielu osobom wydaje się, że mają rzetelną wiedzę na ten temat, ale często tak nie jest. Stąd też moje miłe zaskoczenie. Jestem pod wrażeniem. Zdecydowanie będę rekomendował to miejsce i częściej wpadał, aby zobaczyć nowe rzeczy.

requirement of aluminium strip