Upgrade your roof with high-quality aluminum roofing sheets. Experience long-lasting protection and enhance your home's aesthetics with our stylish and durable roofing solution

Aluminum roofing sheets have emerged as a popular roofing material due to their exceptional properties and benefits. This versatile and durable material is lightweight, corrosion-resistant, and requires minimal maintenance. In this guide, we will explore the key advantages of aluminum roofing sheets, the different types available, factors to consider when choosing them, installation and maintenance tips, and cost considerations.

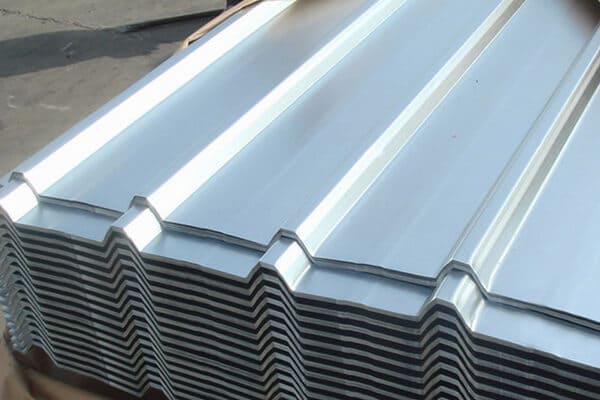

Aluminum Roofing Sheets

According to the alloy composition, 1050 and 1060 belong to pure aluminum, and the aluminum content is above 99.5%;

3003 belongs to aluminum-manganese alloy, which has better alloy hardness and anti-rust function; 3004 also belongs to a series of aluminum-manganese alloys, which has higher strength than 3003, excellent formability and good corrosion resistance, and requires parts with higher strength than 3003 alloy.

3004 Aluminum Roofing Sheet With Film

5052 is an aluminum-magnesium alloy with higher hardness.3004 and 5052 are widely used for aluminum roofing sheet.

Aluminum Alloy 3003: This alloy is widely used for roofing applications due to its excellent formability, corrosion resistance, and durability. It has moderate strength and is easy to work with during installation.

Aluminum Alloy 3105: Similar to Alloy 3003, Alloy 3105 offers good formability and corrosion resistance. It is commonly used in residential roofing projects and has a higher strength compared to Alloy 3003.

Aluminum Alloy 5052: This alloy is known for its high strength and excellent corrosion resistance. It is often used in areas with harsh weather conditions. Alloy 5052 is suitable for both residential and commercial roofing applications.

Aluminum Alloy 6061: Although not as commonly used as the previous alloys, Alloy 6061 is favored for its high strength and good corrosion resistance. It is often utilized in industrial and commercial roofing projects where structural integrity is crucial.

| Characteristic | 3003 Aluminum | 6061 Aluminum |

| Strength | Moderate strength suitable for most residential applications | Higher strength, commonly used in industrial and commercial roofing |

| Corrosion Resistance | Good resistance to corrosion | Good resistance to corrosion |

| Formability | Highly formable, easy shaping and installation | Lower formability compared to 3003, but still workable |

| Weight | Lightweight material, easier installation, reduced stress on roof structure | Relatively heavier, may impact overall weight of the roof system |

| Cost | Generally more affordable | Tends to be more expensive |

| Aesthetic Appeal | Can be coated and finished to achieve desired appearance | Can be coated and finished to achieve desired appearance |

Usually customers will require the surface to be coated, and a small number of customers will choose bare board.

PE (polyester) and PVDF (fluorocarbon) are the most common. The coating color can be selected according to the Raul color card number, and can also be proofed according to customer needs.

Fluorocarbon coatings have strong weather resistance, can withstand the sun and rain, can resist the erosion of various air pollutants such as acid rain and salt spray, and can resist strong ultraviolet radiation and oxidation. The service life is more than 10-20 years.

The weather resistance of polyester coating is average, but it also has a certain degree of anti-ultraviolet ability, which can effectively isolate the pollution of the main material of roof tiles from the outside world, and the service life is 3-5 years.

Customers describe that PVDF should be recommended when the environment is humid near the sea or the environment is harsh.

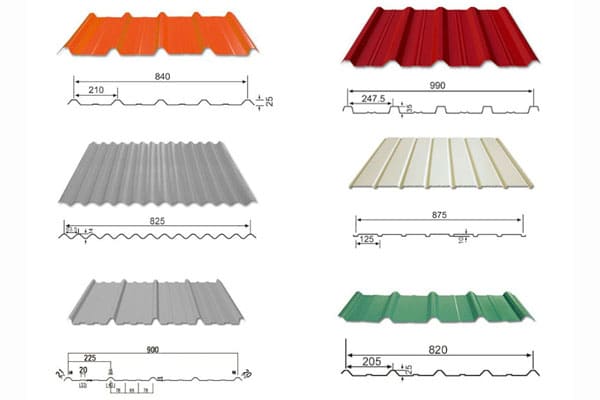

There are many types of aluminum roofing sheet, which can be classified according to different standards;

Aluminum roofing sheet classification by width

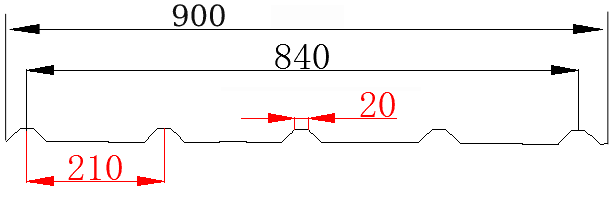

The common effective width of Aluminum Roofing Sheet is 780 820 825 840 875 900 990, which is the effective width.

Note: What is the effective width of the aluminum roofing sheet?

Effective width: the distance from groove to groove quality inspection, not from edge to edge, taking 840 as an example, the distance from groove to groove is 840MM, and the width from edge to edge should be 900MM.

Most customers will choose pe or pvdf coated Aluminum Roofing Sheet, because the coating can improve the service life of Aluminum Roofing Sheet, especially in the seaside with humid air, or the area with very strong ultraviolet rays.

A. Corrugated Aluminum Roofing Sheets:

Features a wavy pattern that adds strength to the sheet.

Commonly used in residential and commercial applications.

Provides excellent drainage capabilities and structural integrity.

B. Standing Seam Aluminum Roofing Sheets:

Consists of interlocking panels that create a sleek and modern appearance.

Suitable for both low-slope and steep-slope roofs.

Offers superior weather resistance and is often used in commercial and high-end residential buildings.

Aluminum roofing panels are commonly used in the Philippines due to their durability, lightweight nature, and resistance to corrosion in the country’s tropical climate. They are available in various profiles, thicknesses, and colors to suit different architectural styles and personal preferences.

A. Durability and Longevity:

aluminum roofing sheet production

B. Energy Efficiency:

Look for aluminum roofing sheets with reflective coatings that maximize energy efficiency and reduce cooling costs.

C. Maintenance and Upkeep:

Aluminum roofing requires minimal maintenance. Consider the ease of cleaning and any specific maintenance requirements.

D. Aesthetic Appeal:

Choose a style and color that complements the architectural design of your building.

Hire a professional roofing contractor experienced in aluminum roof installation.

Ensure proper installation techniques, including fastening methods and sealing for waterproofing.

Regularly inspect the roof for any signs of damage, such as loose or damaged panels.

Clean the roof surface as needed using mild detergent and water.

Remove debris and leaves from gutters and downspouts to prevent clogging and water backup.

More information please visit: https://www.aluroofingsheet.com/

Welcome to Huawei Aluminum, your trusted source for high-quality aluminum coils designed specifically for aluminium roofing sheets.

Get premium 3004 aluminum foil Dubai, perfect for packaging, construction, and industrial applications. Lightweight, corrosion-resistant, and highly durable!

3mm aluminum sheet refers to an aluminum sheet with a thickness of 3mm, and 3mm is a common thickness of aluminum sheet

The 1000 series aluminum sheet is a series of pure aluminum sheets. Its composition is mainly aluminum, with a content of more than 99%.

Discover LDPE composite aluminum foil, designed for superior moisture resistance, thermal insulation, and versatile applications in packaging, construction, and more.

Huawei Aluminum aluminum discs are widely exported to Ghana, Guatemala, Burkina Faso, Algeria, Togo, Kenya, Nigeria, South Africa, Morocco and other African countries; the United Arab Emirates, Yemen, Qatar, Kuwait, Iran, Jordan, Saudi Arabia and other Middle East nation.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

Our required qty: Aluminium Sheet in coil (620mm X 1.20mm) Qty: 200 MT. Can you give me the number of contact urgently. Thanks Matiur Rahman Director of Technical Sales dept.

Bonjour ; Nous sommes une compagnie de spectacle de rue " compagnie carabosse " nous travaillons avec la flamme . nous sommes à la recherche de tôle reflecteur en aluminium pour pouvoir crée un nouvelle objet à base d'un fil métal enflammé liquide éthanol d' une hauteur environ 1 m . Quels produits avez vous à nous proposez ? Cordialement Fabrice

Hello, I am interested in 3*1500*3500 mm 5754 H111 Checkered Aluminium Plate - Diamond Shape Powermaster Ltd. Moscow, Volokolamskoe shosse 1, str. 1, of. 19, Moscow, 125080

Buenos días, Me interesaría saber el costo de Paneles de nido de abeja de aluminio para usar como refuerzo interior de bandejas, estantes , mesadas que realizamos en acero inoxidable AISI 304. De espesor del panel de 10 y 20 mm, con la piel superior e inferior de aluminio espesor 0.8 mm liso o cepillado o solo el núcleo del nido de abeja de aluminio; con tamaño de celda de 10 o 15 mm ( o estándar ) . tamaño de las planchas de 1500 x 3000 mm o la lo que recomiende para el uso que le quiero dar. Desde ya muchas gracias

Proszę o ofertę na blachę aluminiową grubość 20 mm, w gatunku 1060. 8000 kg