Aluminum strips can be classified by many aspects, such as alloy, surface treatment process, size and use, etc., aiming to give you a clearer understanding of aluminum strips.

The raw materials of aluminum strip (Aluminum strip/Aluminum strip) are pure aluminum or aluminum alloy cast-rolled aluminum coils and hot-rolled aluminum coils. They are rolled by a cold rolling mill into thin aluminum coils of different thicknesses and widths, and then slit according to the purpose. The machine cuts longitudinally into aluminum strips of different widths.

Definition of aluminum strips

Aluminum strips have the advantages of light weight, high strength, and good corrosion resistance, and are widely used in various fields.

Aluminum strips are lightweight and high-strength. Compared to other metal materials, aluminum strips are lighter in weight but relatively stronger, making them ideal for manufacturing a variety of lightweight structures and equipment. Its high strength also makes the aluminum strip more resistant to wear and impact during application.

Aluminum strip has good corrosion resistance. Due to the protection of the oxide film on the surface, the aluminum strip can effectively prevent the occurrence of oxidation corrosion and reduce maintenance and upkeep costs. This makes aluminum strips widely used in chemical industry, electric power, communications and other fields to manufacture corrosion-resistant equipment and components.

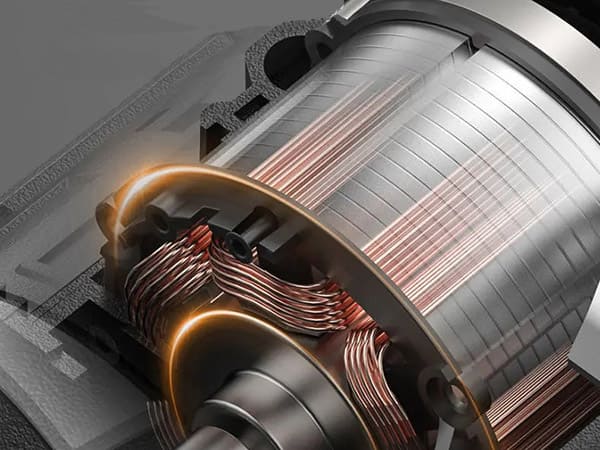

The electrical and thermal conductivity properties of aluminum strips are also noteworthy. Aluminum strips have excellent electrical and thermal conductivity properties, making them widely used in electronic components, cables and wires. Aluminum strip’s high thermal conductivity also makes it a good choice as a heat sink material.

Huawei aluminum strips

Slitting process of aluminum strip

Aluminum strips can be classified by many aspects, such as alloy, surface treatment process, size and use, etc., aiming to give you a clearer understanding of aluminum strips.

Pure aluminum strip is a strip material made by pure aluminum and usually has excellent electrical conductivity, thermal conductivity and corrosion resistance. It can be widely used in electronics, packaging, construction, aerospace and automotive fields.

1000 series pure aluminum strip: pure aluminum or aluminum containing a small amount of impurities, such as 1050, 1060, 1100, etc., mainly used in food packaging, electronic foil, chemical containers and other fields, with good conductivity and corrosion resistance.

According to the different alloying elements added, aluminum alloys can be divided into silicon aluminum alloys, aluminum manganese alloys, aluminum titanium alloys, aluminum copper alloys, aluminum magnesium alloys and other types.

For example, silicon-aluminum alloys use silicon as the main alloy element, which can improve the hardness and strength of aluminum; aluminum-manganese alloys can improve the oxidation resistance and corrosion resistance of aluminum; aluminum-titanium alloys can improve the processing performance and mechanical properties of aluminum, etc. . Different combinations of alloy elements can give alloy aluminum different performance characteristics.

3000 series aluminum strip: This type of alloy mainly adds manganese element, such as 3003 and 3004 aluminum strip, etc., which improves the mechanical strength and corrosion resistance of the material. It is often used in containers, pipes, heat sinks, kitchen utensils, and automobile parts.

3003 aluminum strip display

5000 series aluminum strips: Mainly added with magnesium element, such as 5052, 5083, 5754 aluminum strips, etc. This series of aluminum strips have good corrosion resistance, weldability and medium strength, and are widely used in ships, vehicles, tankers, and pressure vessels , bridge structures, curtain wall systems, etc.

6000 series aluminum strips: such as 6061 and 6063 aluminum strips, etc., contain magnesium and silicon, can be strengthened through heat treatment, have good comprehensive properties, and are widely used in building profiles, industrial frames, rail transit, etc.

8000 series aluminum strip: This series of aluminum strips sometimes add iron and other alloy elements, such as 8011 aluminum strip, which is mainly used for pharmaceutical foils, beer caps, cable foils, core materials of composite materials, etc.

Aluminum strips have the advantages of light weight, high strength, and corrosion resistance, so they are widely used in various fields.

Aluminum strips are also classified according to different applications, such as aerospace aluminum strips, construction aluminum strips, automotive aluminum strips, etc.

Aluminum strips for aerospace use need to have excellent strength, rigidity and heat resistance; aluminum strips for construction need to have good weather resistance and corrosion resistance; aluminum strips for automobiles need to have lower density, high strength and excellent Forming performance, etc.

Aluminum strips for aluminum winding

Different uses have different requirements for the performance and composition of aluminum strips. The following are aluminum strips for different uses:

1. Aluminum strip for packaging: Aluminum strip is widely used in the packaging industry, especially for packaging food, medicine, cosmetics and other products. Aluminum strips are easy to form and have good sealing and thermal insulation properties, which can effectively protect product quality and safety.

2. Aluminum strips for construction: Aluminum strips are widely used in the construction industry to manufacture building exterior wall decorative panels, roofing materials, doors and windows and other products. Aluminum strips have excellent corrosion resistance and lightweight properties, and can meet the requirements of building materials for weathering resistance and aesthetics.

3. Aluminum strips for electronic products: Aluminum strips also have important uses in the electronics industry and can be used to manufacture components such as casings, radiators and connectors for mobile phones, tablets, TVs and other products. Aluminum strips have good thermal conductivity and mechanical strength and can meet the needs of electronic products for heat dissipation and protection.

4. Aluminum strip for insulating glass: Aluminum strip for insulating glass is an important material used in the production of insulating glass. It plays an important role in the production process of insulating glass. Insulating glass is a new type of building material made by injecting dry air or other gases between two pieces of glass. It has the advantages of heat insulation and sound insulation, and has been widely used in the construction industry.

Hollow glass aluminum strip

5. Battery shell material: Aluminum strip can be used to make the battery shell. As a protective shell of the battery, it can protect the internal structure and materials of the battery, prevent the impact of the external environment on the battery, and also improve the appearance quality of the battery. , increase the beauty and service life of the battery.

6. Aluminum strips in the automobile manufacturing industry: Aluminum strips are widely used in the automobile manufacturing industry and are used to manufacture automobile bodies, engine parts, wheels and other products. Aluminum strips are lightweight, high-strength and have excellent processing properties, which can effectively improve the energy-saving performance and safety performance of automobiles.

7. Aluminum strip for aerospace: Aluminum strip is one of the important materials in the aerospace field and can be used to manufacture aircraft structural parts, engine parts, spacecraft shells and other products. Aluminum strips have good heat resistance and corrosion resistance and can meet the requirements of aerospace products for light-to-weight ratio and high-temperature performance.

Aluminum strips can also be further classified according to surface treatment methods. The main purpose is to improve the corrosion resistance, wear resistance, aesthetics and meet specific functional requirements of the aluminum strips. The following are some common surface treatment processes for aluminum strips:

Anodizing is an electrolytic oxidation process that significantly improves its corrosion resistance and wear resistance by forming a dense aluminum oxide film (Al₂O₃) on the surface of the aluminum strip. It can also be dyed to achieve various color effects.

By placing the aluminum strip in an electrophoresis tank and energizing it, a resin film is deposited on the surface. The resulting coating is smooth and has strong adhesion, which not only provides excellent anti-corrosion protection, but also gives the aluminum strip an excellent decorative effect.

Electrostatic powder spraying uses high-voltage electrostatic adsorption of powder coating on the surface of an aluminum strip, and then solidifies it at high temperature to form a coating. It has high mechanical strength and weather resistance, rich colors and is environmentally friendly.

Gold aluminum strip

The fluorocarbon spraying process uses fluoropolymer coatings to form a coating with extremely high weather resistance, corrosion resistance and self-cleaning properties. It is especially suitable for surface treatment of aluminum strips in long-term outdoor exposure environments.

Brushing can give the aluminum strip a delicate texture, showing a satin or hairline effect, increasing texture; polishing can make the surface of the aluminum strip achieve a mirror effect with extremely high gloss.

By high-speed jetting of sand particles onto the surface of the aluminum strip, the surface oxide layer is removed and a micro-rough surface is formed, which can achieve a matte or frosted effect and enhance the visual effect and feel of the product.

Aluminum strips are electroplated with a layer of other metals, such as zinc, chromium, nickel or other alloys, to improve their appearance, wear resistance and corrosion resistance.

It includes steps such as degreasing, pickling, and chemical conversion treatment to remove grease and oxide layers on the surface of the aluminum strip and improve the quality of subsequent coating or anodizing processes.

A layer of plastic film or metal film can be laminated or vacuum evaporated on the surface of the aluminum strip to provide additional protection or special visual effects.

Thin aluminum sheet typically refers to a flat piece of aluminum material that has a thickness of less than 6mm (0.24 inches).

8021 aluminum foil has the characteristics of cleanliness and hygiene, and can be made into an integrated packaging material with many other packaging materials. In addition, the surface printing effect of 8021 aluminum foil is better than other materials. Therefore, 8021 aluminum foil alloy can also be used in the field of food packaging.

7075 aluminum sheet is the strongest heat-treatable alloy, introduced by Alcoa in 1943, and can be heat-treated to achieve strength levels comparable to many steel alloys.

Cold rolled aluminum strip is a thin strip made of aluminum alloy that is processed by cold rolling. It is widely used in aerospace, automobile manufacturing, building materials and other fields.

Factory hot selling thick aluminum foil, thin aluminum foil, household packaging aluminum foil, food packaging foil, medicinal aluminum foil

The 3003 aluminium strip is made of 3003 aluminium alloy. The 3 series aluminum alloy is also called an aluminum-manganese alloy.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

Dear Sir, Please offer your best FOB Prices specs are as under ALUMINIUM STRIP (AL=99.50% MIN) SIZE:450 X32 X6 MM. DIN EN 570 EN-AW 1050 A, QUANTITY=3400KG

Hello, Would you be so kind to offer item as follows: Coil 0,6х1250 (1000)mm EN AW-3105 5tons

Hello, Can you offer me Aluminium plates? Actally I need: 110mm x 1700mm x 1700mm 5083 H111 - 21 pcs Next year planed is 177 pcs

Świetny artykuł. Byłem zachwycony, że wyszukałem ten artykuł. Wielu osobom wydaje się, że mają rzetelną wiedzę na ten temat, ale często tak nie jest. Stąd też moje miłe zaskoczenie. Jestem pod wrażeniem. Zdecydowanie będę rekomendował to miejsce i częściej wpadał, aby zobaczyć nowe rzeczy.

requirement of aluminium strip