Both hot rolling and casting rolling are a process of aluminum processing, and products produced under different processes will have differences in performance.

Hot rolling is relative to cold rolling, cold rolling is rolling below the recrystallization temperature, and hot rolling is rolling above the recrystallization temperature.

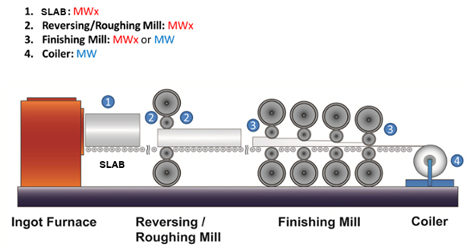

Hot rolling process

Hot rolling generally refers to rolling metal above the crystallization temperature. In the hot rolling process, metal deformation has both a hardening process and a softening process. Due to the effect of the deformation rate, as long as the recovery and recrystallization process is too late, the metal will work harden with the increase in the degree of deformation.

However, in the hot rolling temperature range, the softening process dominates. Therefore, at the end of hot rolling, the recrystallization of metal is often incomplete, and the hot-rolled aluminum alloy strip presents a microstructure state in which recrystallization and deformation microstructure coexist.

Hot rolling equipment

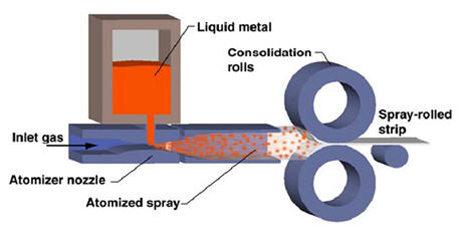

Casting, also known as ingotless rolling, is a forming method that combines casting and rolling. The diagram below illustrates the basic principle of this molding method.

Casting and rolling process

Casting is a new technique of directly “casting” molten metal into semi-finished or finished products. The distinctive feature of this process is that its crystallizer is two rotating casting rolls with a water cooling system, and the melt is solidified and hot rolled between the rolls, which is completed in a short time (2~3s).

Casting and rolling is a new technology developed in the 1970s. The advantage is that the molten metal is directly crystallized, cast and rolled by the rotary mold to directly produce metal products.

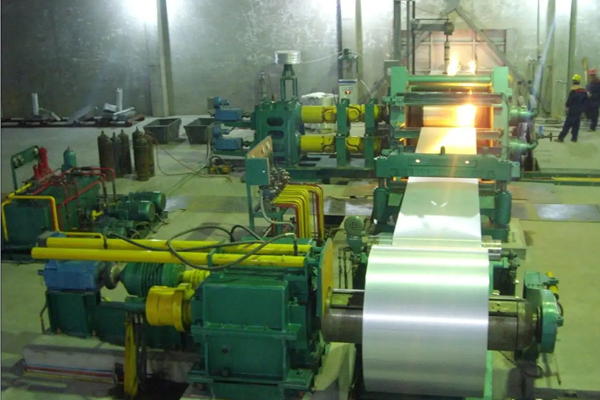

Casting and rolling equipment

What is the difference between hot rolled aluminum sheet and cast rolled aluminum sheet? This should be a big problem that plagues many small partners who are new to the aluminum processing industry. It’s actually very simple. One is heat treated and one is not. Basically in line with the literal meaning. Below Huawei Aluminum Company will introduce the difference between the two in detail.

Difference Between Hot Rolled (DC) and Cast Rolled (CC)

Many customers buy aluminum sheets for the first time and may not know much about the product. They don’t know whether to choose cast-rolled or hot-rolled aluminum. It doesn’t matter if they don’t know. Just tell our customer service staff in detail. We will arrange a professional business manager for you and recommend suitable products according to your needs.

Huawei Aluminum provides low-cost high-quality aluminum sheets, aluminum coils, aluminum foils, aluminum strips, and aluminum disc products, 1000 series, 3000 series, 5000 series, and 6000 series plates with a thickness of 0.1-500mm, and the main alloy models are 1050, 1060, 1100 , 3003, 3004, 3104, 3105, 5005, 5052, 5083, 5754, 6061 aluminum sheet, etc.

Food packaging, household foil raw material 3004 aluminum foil, professional aluminum alloy production expert, 20 production lines

Huawei Aluminum is a large-scale 5052 aluminum foil raw material manufacturer, with 30 years of experience in aluminum foil production and sales.

0.75 aluminum sheet refers to an aluminum sheet with a thickness of 0.75 inches, also known as 0.75" aluminum sheet;

3003 aluminum sheet is an alloy with very good corrosion resistance and moderate strength, the reason this metal is widely used is because it is affordable and strong.

5454 aluminum circles have all the properties of 5454 aluminum alloy and are often used in can sealing, non-stick pot bottoms, traffic signs, lampshades, etc.

6061-T6 Aluminum floor plate, commonly known as “diamond plate” or “tread plate”, is an excellent candidate for most processing techniques and both interior and exterior applications.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

Dear Sir, Please offer your best FOB Prices specs are as under ALUMINIUM STRIP (AL=99.50% MIN) SIZE:450 X32 X6 MM. DIN EN 570 EN-AW 1050 A, QUANTITY=3400KG

Hello, Would you be so kind to offer item as follows: Coil 0,6х1250 (1000)mm EN AW-3105 5tons

Hello, Can you offer me Aluminium plates? Actally I need: 110mm x 1700mm x 1700mm 5083 H111 - 21 pcs Next year planed is 177 pcs

Świetny artykuł. Byłem zachwycony, że wyszukałem ten artykuł. Wielu osobom wydaje się, że mają rzetelną wiedzę na ten temat, ale często tak nie jest. Stąd też moje miłe zaskoczenie. Jestem pod wrażeniem. Zdecydowanie będę rekomendował to miejsce i częściej wpadał, aby zobaczyć nowe rzeczy.

requirement of aluminium strip