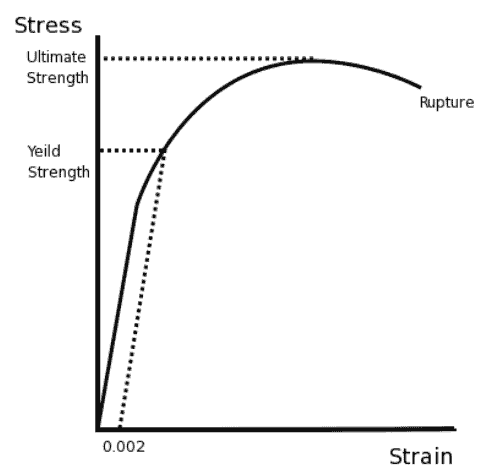

A simplified definition of a fabric’s power is its potential to withstand a positive quantity of load, also known as force or strain, earlier than it reaches specific factors of deformation or strain. A normal way of visualizing this is by the well-known stress-strain curve, proven in the example under.

Stress strain graph aluminum

Those curves are commonly made by means of using a sample of material, which includes aluminum, and making use of tensile pressure to motive deformation up till the factor of rupture. The pressure, and consequently the power of the fabric, is typically measured in gadgets of megapascals (MPa) or kilopounds consistent with square inch (ksi). Deformation is measured as a percent of the authentic length of the sample.

The strength of metallic materials can be measured by several indicators:

Tensile Strength: The maximum force or pressure that a metal material can withstand under tensile stress. Tensile strength is usually expressed in megapascals (MPa).

Yield Strength: The point at which a metallic material begins to plastically deform or flow under tensile stress. It is the ability of a metal material to resist deformation. Yield strength is usually expressed in megapascals (MPa).

Elongation: The degree to which a metal material undergoes plastic deformation during stretching. It expresses the percentage by which a material is able to elongate before breaking.

Fracture Toughness: The ability of a metal material to resist fracture. It is the ability of a material to resist fracture when subjected to stress concentrations.

Aluminum bending test

These indicators reflect the strength and deformation ability of metal materials when they are subjected to external forces. Different metal materials have different strength properties, so when selecting and designing a metal structure or part, the strength of the material needs to be considered to ensure it meets the intended application needs.

The strength of materials can be measured by several common test methods:

Tensile Test: This is one of the most commonly used testing methods to measure the performance of materials under tensile stress. In the tensile test, the standard sample is stretched, and the stress and strain of the sample are measured at the same time, so as to determine the tensile strength, yield strength, elongation, etc. of the material.

Compression Test: This test method is used to measure the performance of materials under compressive stress. The specimen is compressed while stress and strain are measured to determine the material’s compressive strength and ability to deform.

Bending Test: This test method is used to evaluate the performance of materials under bending loading. The specimen is bent to apply force to measure bending stress and strain and to determine the bending strength and toughness of the material.

Hardness Test: Hardness testing is a quick way to assess the strength of a material. Commonly used hardness testing methods include Brinell Hardness, Rockwell Hardness and Vickers Hardness.

Impact Test: Impact testing is used to evaluate the strength and toughness of materials under impact loads. Commonly used impact test methods include Charpy Test and Izod Test.

Metal after stress strain test

These test methods can provide quantitative data on properties such as strength, deformability, and toughness of materials. Depending on the application needs, it is very important to choose the appropriate test method to evaluate the strength of the material. At the same time, attention should also be paid to factors such as test conditions, standard specifications, and sample preparation to ensure the accuracy and comparability of test results.

Aluminum alloy materials can be divided into low-strength aluminum alloys, medium-strength aluminum alloys and high-strength aluminum alloys according to their strength;

The strength classification is not a strict dividing line, and different aluminum alloy materials can overlap within the strength range. In addition, the specific composition and heat treatment process of aluminum alloy will also affect its strength characteristics;

The strength of different grades of aluminum alloys is different. For example, the strength of 3004 aluminum alloy is much higher than that of 1050, 1060, 1100 and other alloys;

The strength of aluminum alloys of the same grade is also different under different heat treatment states

| Strength | 3004-O | 3004-H | 3004-T |

| Tensile Strength | 125-165 MPa | 165-215 MPa | 165-205 MPa |

| Yield Strength | 100-140 MPa | 145-190 MPa | 145-180 MPa |

| Elongation | 15%-25% | 5%-15% | 10%-20% |

| Hardness | 30-45 HB | 50-65 HB | 45-55 HB |

Some aluminum alloys have high strength, even comparable to steel. Comparing the strongest aluminum alloy with the same size as steel, steel is generally the strongest.

As an instance, the most tensile energy of one of the normally-determined most powerful aluminum alloys, the AA7068-T6, and one of the strongest metallic alloys, the AISI 1080, are 710MPa and 965MPa, respectively. Here you may see a contrast in their Yield energy and remaining Tensile strength.

| Materials | Yield Strength | Maximum Tensile Strength |

| AA 7068-T6 Aluminum Alloy | 683MPa | 710MPa |

| AISI 1080 Steel | 585MPa | 965MPa |

When it comes to strength-to-weight ratios, aluminum wins out because it’s only 1/3 the weight of steel with little difference in strength, and it wins when it comes to performance.

When choosing materials, strength is not the only measure, but the strength-to-weight ratio can highlight the performance of materials.

| Aluminum Alloy | Maximum Tensile Strength | Applications |

| 2024 | 465MPa | High-strength structural applications, aircraft fittings, missile parts, pistons. |

| 5052 | 228MPa | Pressure vessels, tanks, architectural uses, automotive parts, railroad cars. |

| 6061 | 310MPa | Truck components, pipelines, recreation vehicles, aircraft, automotive parts. |

| 7075 | 572MPa | Highly-stressed structural and aircraft parts, machine parts, ordnance. |

Aluminum alloys for aircraft

Compared with other alloy foils of series 1, such as 1060 and 1070 aluminum foils, the content of (Fe+Si) in 1100 aluminum foil is higher than both, and the content of Fe is the key factor to improve the strength and toughness

We use the pure aluminum ingots to manufacture 5mm aluminum sheets. They come in various widths and tempers. They are not only suitable for marine grade, but also for automobile manufacturing, pressure vessels, including water tanks, oil tanks, and the maximum width we can produce is 3000mm.

Embossed aluminum sheet is an aluminum product that is rolled on the basis of pure aluminum plate or aluminum alloy plate to form various patterns on the surface.

3004 Aluminum Sheet is a medium-strength aluminum alloy with manganese and magnesium as the main alloying elements. Its strength is higher than 3003 Aluminum Sheet, but the ductility is lower.

As a professional manufacturer and exporter of aluminum foil jumbo roll seals in China. We have been in this field for more than 20 years, we have a factory and dust-free workshop of more than 100,000 square meters

If you are looking for top-quality prepainted aluminum coils with various alloy models and specifications, Huawei Aluminum is your ultimate choice.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

Dear Sir, Please offer your best FOB Prices specs are as under ALUMINIUM STRIP (AL=99.50% MIN) SIZE:450 X32 X6 MM. DIN EN 570 EN-AW 1050 A, QUANTITY=3400KG

Hello, Would you be so kind to offer item as follows: Coil 0,6х1250 (1000)mm EN AW-3105 5tons

Hello, Can you offer me Aluminium plates? Actally I need: 110mm x 1700mm x 1700mm 5083 H111 - 21 pcs Next year planed is 177 pcs

Świetny artykuł. Byłem zachwycony, że wyszukałem ten artykuł. Wielu osobom wydaje się, że mają rzetelną wiedzę na ten temat, ale często tak nie jest. Stąd też moje miłe zaskoczenie. Jestem pod wrażeniem. Zdecydowanie będę rekomendował to miejsce i częściej wpadał, aby zobaczyć nowe rzeczy.

requirement of aluminium strip