Explore the benefits of 3003 H14 aluminum coil for lithium battery shell. Lightweight, formable, and corrosion-resistant—ideal for EV, cylindrical, and prismatic cell casings.

The global rise in electric vehicles (EVs) and energy storage systems has triggered soaring demand for advanced materials in lithium battery manufacturing.

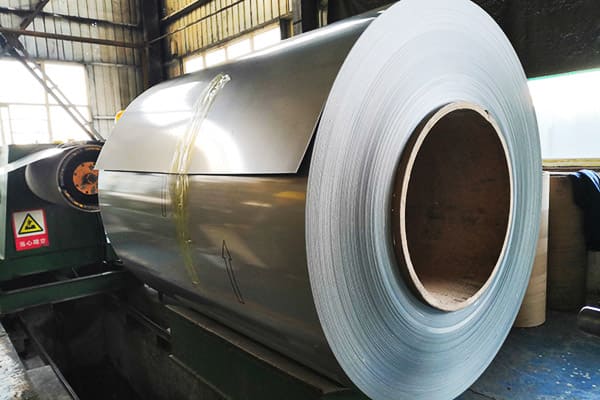

One such material gaining traction is the 3003 H14 aluminum coil for lithium battery shell applications.

Combining lightweight properties, excellent formability, and corrosion resistance, 3003 H14 offers a practical solution for safe and efficient battery enclosures.

In this article, we explore the material’s composition, performance in lithium battery environments, manufacturing advantages, and how it compares to other alloys.

3003 H14 aluminum coil for Lithium battery shell

Here’s a detailed breakdown of the chemical makeup of 3003 aluminum alloy, suitable for battery shell applications:

| Element | Typical Content (%) |

|---|---|

| Aluminum (Al) | 96.6 – 98.6 |

| Manganese (Mn) | 1.0 – 1.5 |

| Copper (Cu) | 0.05 – 0.20 |

| Silicon (Si) | ≤ 0.6 |

| Iron (Fe) | ≤ 0.7 |

| Zinc (Zn) | ≤ 0.1 |

| Titanium (Ti) | ≤ 0.15 |

| Chromium (Cr) | ≤ 0.1 |

| Others (each) | ≤ 0.05 |

| Others (total) | ≤ 0.15 |

3003 is a non-heat-treatable alloy that gains strength primarily through cold working.

The H14 temper indicates that the coil has been strain-hardened to 50% hardness.

This gives it moderate strength while maintaining excellent formability—an ideal balance for deep drawing and forming required in lithium battery shells.

The table below summarizes the typical mechanical properties of 3003 H14 aluminum coil as used in lithium battery shell applications:

| Property | Typical Value | Unit | Remarks |

|---|---|---|---|

| Tensile Strength (Ultimate) | 140 – 180 | MPa | Provides sufficient strength for structural stability in shell designs |

| Yield Strength | ≥ 120 | MPa | Ensures the shell resists permanent deformation under internal cell pressure |

| Elongation (at 50 mm) | ≥ 5 | % | Indicates good ductility for deep drawing and forming |

| Hardness (Brinell) | ~47 | HB | Moderate hardness supports impact resistance without cracking |

| Modulus of Elasticity | ~69,000 | MPa | Reflects stiffness and resistance to elastic deformation |

| Fatigue Strength | ~55 | MPa | Suitable for cyclic loading conditions in mobile or EV applications |

| Poisson’s Ratio | ~0.33 | — | Standard value for aluminum alloys |

| Shear Strength | ~110 | MPa | Supports resistance against twisting and lateral forces |

The material’s ductility allows for deep drawing, stamping, and bending operations—critical processes in shaping cylindrical and prismatic battery housings.

Manufacturers favor 3003 H14 for achieving consistent wall thickness in tightly toleranced enclosures.

While not the strongest alloy, 3003 H14 delivers adequate structural integrity to protect internal battery components from mechanical stress and handling during transport and installation.

Power Banks and Portable Energy Storage

Thanks to its manganese content, 3003 exhibits strong resistance to oxidation and mild acids, protecting the shell from moisture, air, and electrolyte vapors—especially important in sealed battery packs.

At about one-third the weight of steel, 3003 H14 enhances energy density by reducing overall battery module mass.

This directly improves EV range and energy system portability.

Compared to higher-strength alloys like 5052 or stainless steel, 3003 H14 aluminum coil for lithium battery shell applications provides significant cost savings, especially for high-volume manufacturing.

Battery assembly processes involve spot welding, laser welding, or adhesive bonding.

3003 H14 performs well under moderate heat exposure without warping, helping maintain shell integrity.

3003 adheres easily to polymer coatings, insulating films, and adhesives, improving safety and preventing electrical shorts within battery packs.

Although not immersed in electrolytes directly, shell materials must resist chemical vapor or accidental leaks.

3003 aluminum offers stable performance in such controlled environments.

Huawei 3003 H14 aluminum coil

In certain designs, the shell may act as a grounding layer or electromagnetic shield.

With ~38% IACS conductivity, 3003 H14 provides functional benefits beyond structural support.

The 3003 H14 aluminum coil is typically available in:

Battery-grade coils often undergo:

It supports:

These methods allow precise assembly of thin-walled enclosures.

Aluminum’s high recyclability supports sustainable battery production. 3003 H14 retains value after end-of-life and aligns with EV circular economy principles.

Choosing the right material for battery shell design involves a balance of strength, formability, weight, corrosion resistance, and cost.

While 3003 H14 aluminum coil for lithium battery shell applications is a popular choice, it’s essential to understand how it compares with other commonly used materials such as 1060 aluminum, 5052 aluminum, and 304 stainless steel.

The following table provides a side-by-side technical comparison:

| Property / Material | 3003 H14 Aluminum | 1060 Aluminum | 5052 Aluminum | 304 Stainless Steel |

|---|---|---|---|---|

| Alloy Type | Al–Mn | Pure Aluminum (99.6%) | Al–Mg | Fe–Cr–Ni Austenitic Steel |

| Tensile Strength (MPa) | 140–180 | 95–125 | 210–260 | 515–620 |

| Yield Strength (MPa) | ≥120 | ~45 | ~160 | ~215 |

| Elongation (%) | ≥5 | ≥15 | ≥10 | ≥45 |

| Formability | Excellent (deep drawing grade) | Excellent | Good | Moderate (requires high force) |

| Corrosion Resistance | Good | Moderate | Excellent | Excellent |

| Density (g/cm³) | 2.73 | 2.71 | 2.68 | 7.93 |

| Electrical Conductivity | ~38% IACS | ~61% IACS | ~35% IACS | ~3% IACS |

| Weldability | Good | Excellent | Good | Moderate |

| Cost | Low | Very Low | Medium | High |

| Recyclability | High | High | High | High |

| Suitability for Battery Shell | ✅ Excellent | ✅ Adequate | ✅ Excellent (for structural use) | ⚠️ Overqualified (too heavy) |

Thanks to its excellent formability, corrosion resistance, and cost-effectiveness, 3003 H14 aluminum coil has become a material of choice for manufacturers of lithium battery shells across multiple industries.

Whether used in cylindrical cells for consumer electronics or large prismatic units for EVs, this aluminum alloy meets the technical and commercial demands of today’s energy systems.

Cylindrical lithium-ion cells are widely used in laptops, power tools, and electric vehicles.

These cells require shells that are lightweight, seamless, and strong enough to contain internal pressure changes.

The deep-drawing capability of 3003 H14 aluminum makes it ideal for forming the narrow, round housings of 18650 and 21700 batteries with precision.

Additionally, its smooth surface and good weldability support laser sealing at the cell cap, enhancing safety and production speed.

3003 H14 aluminum coil for Cylindrical Cells

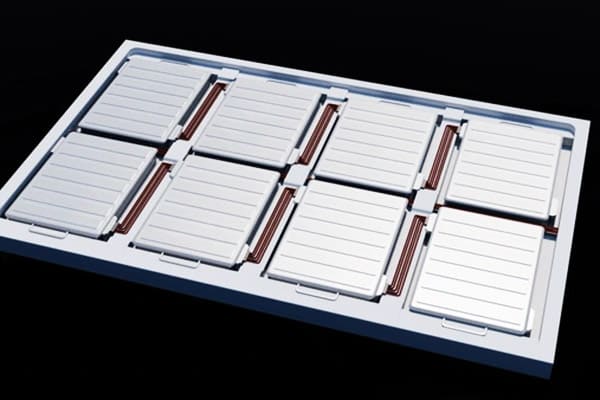

As electric vehicles and energy storage systems demand higher energy densities, prismatic cells have grown in popularity.

These larger, rectangular formats benefit from aluminum shells that can be bent and joined into modular blocks.

The moderate strength and formability of 3003 H14 allow for tightly folded corners and thin-wall sections that reduce space and weight without compromising protection.

In this context, 3003 H14 provides a superior alternative to heavier stainless steel or lower-strength pure aluminum, offering the right balance of mechanical support and processing efficiency.

Portable devices, such as power banks, mobile chargers, and backup battery systems, require slim, stylish casings that can endure daily handling and occasional impacts.

3003 H14 aluminum is frequently chosen for its attractive surface finish, which can be further enhanced with anodizing or decorative coatings.

It offers both mechanical protection and aesthetic appeal, especially in consumer-facing products.

Moreover, its lightweight nature improves product ergonomics and energy efficiency by reducing the overall mass of the battery pack.

In electric vehicles and smart grids, battery enclosures must meet stringent requirements for safety, heat dissipation, recyclability, and mass production compatibility.

3003 H14 aluminum coil supports these needs through:

EV Battery Modules used 3003 H14 aluminum coil

As lithium battery production scales, supply reliability becomes critical. Henan Huawei Aluminum, a leading Chinese supplier, offers:

Their products undergo rigorous quality inspections, ensuring uniformity for automated fabrication.

Choosing 3003 H14 aluminum coil for lithium battery shell design is a strategic decision balancing performance, manufacturability, and cost.

Its deep drawing capabilities, corrosion resistance, and lightweight nature make it ideal for cylindrical and prismatic cell casings.

Whether you’re scaling battery pack production for EVs or developing compact energy solutions, 3003 H14 offers a proven, efficient material foundation.

Partnering with qualified suppliers like Henan Huawei Aluminum ensures consistency, compliance, and peace of mind in high-volume operations.

Q1: Is 3003 H14 suitable for high-voltage battery systems?

Yes, when properly coated or insulated, 3003 H14 can be safely used in high-voltage enclosures.

Q2: Can 3003 H14 aluminum coil be used in pouch cells?

It is generally not used for pouch cells, which prefer laminated foils. However, it may be used for outer casings in modular systems.

Q3: What are the standard thicknesses used for battery shells?

Typical thickness ranges from 0.3mm to 1.2mm, depending on the battery type and application.

Q4: How does surface cleanliness affect battery safety?

A clean, oil-free surface prevents contamination, ensuring adhesion of films and reducing fire risk during operation.

Q5: Where can I buy 3003 H14 aluminum coil for lithium battery shell applications?

Trusted suppliers like Henan Huawei Aluminum offer certified coils with consistent quality for industrial use.

Thin aluminum sheet typically refers to a flat piece of aluminum material that has a thickness of less than 6mm (0.24 inches).

Huawei Aluminum is your reliable partner for 0.5mm aluminum coils, and we are committed to meeting your aluminum needs with a wide range of alloy models and specifications.

Contact us today to learn more about our 5083 aluminum coil offerings and how we can meet your specific requirements.

Air conditioner aluminum foil is a material used to make air conditioner heat exchangers. Its main features are light and thin, good thermal conductivity, and corrosion resistance.

Reflective aluminum sheet is a metal sheet with high reflectivity and is widely used in optics, electronics, construction and other fields. This article will introduce the principles, characteristics and applications of Reflective aluminum sheets.

3003 Aluminum Perforated Sheets are obtained by punching 3003 aluminum alloy sheets and are often used in architectural decoration, food processing machinery and other fields.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

Dear Sir, Please offer your best FOB Prices specs are as under ALUMINIUM STRIP (AL=99.50% MIN) SIZE:450 X32 X6 MM. DIN EN 570 EN-AW 1050 A, QUANTITY=3400KG

Hello, Would you be so kind to offer item as follows: Coil 0,6х1250 (1000)mm EN AW-3105 5tons

Hello, Can you offer me Aluminium plates? Actally I need: 110mm x 1700mm x 1700mm 5083 H111 - 21 pcs Next year planed is 177 pcs

Świetny artykuł. Byłem zachwycony, że wyszukałem ten artykuł. Wielu osobom wydaje się, że mają rzetelną wiedzę na ten temat, ale często tak nie jest. Stąd też moje miłe zaskoczenie. Jestem pod wrażeniem. Zdecydowanie będę rekomendował to miejsce i częściej wpadał, aby zobaczyć nowe rzeczy.

requirement of aluminium strip