The production process of 5052 aluminum alloy is: melting and casting → ingot sawing and milling → billet heating → hot rolling → cold rolling → finished product annealing → cross cutting → packaging.

5052-H32 Aluminum Alloy

On-line double rotor degassing, then use Al5TiB in the chute to refine the grain, and finally filter through the ceramic filter plate, enter the crystallizer and cast into a flat ingot of 630mm×1400mm×8000mm.

The ingot is cut off by a sawing machine, and then enters the milling machine for peeling, removing the surface segregation layer and oxide scale, and then transfers to the heating furnace for heating. Heating process system: 480 ° C for 3 hours, after the heat preservation is completed, it is taken out of the furnace and rolled.

The high-temperature ingot undergoes 19 passes of hot rough rolling to become an intermediate billet. After cutting the material head, it enters the 4-stand hot finish rolling mill. After continuous rolling and thinning, high-temperature coiling begins to control the hot-rolled coil The thickness is 6.7mm, the final rolling temperature is 325°C±5°C, and the coil is naturally cooled after it is off the machine.

The cooled hot-rolled coils are rolled out of the finished products one by one on the cold rolling mill, and the total processing rate of cold rolling is 25%. In addition, the cold rolling mill must control the angle and air pressure of the edge purge to prevent oil and splash on the surface of the coil, so as to reduce the risk of oil spot defects.

For direct annealing without cleaning, it is first necessary to ensure that there are no oil spots on the surface of the coil, and it is also necessary to ensure that the residual oil can be completely volatilized, and the process window is very narrow. If the temperature is too low, there will be no oil spots, but there will be residual oil; if the temperature is too high, there will be no residual oil, but there will be oil spots.

The special annealing process system adopted:

In the first stage, the furnace gas is set to 180°C, the heating rate is set to 35°C/h, and the negative pressure and purging are turned on to play the role of pre-drying in the air environment;

In the second stage, when the furnace gas reaches 180°C, start filling N2 gas to control the oxygen content in the furnace below 0.1%, and then keep it warm for 6 hours to play the role of pre-drying in an oxygen-free environment. Will cause oil spots due to oxidation;

In the third stage, the furnace gas is changed to 235°C, and the heating rate is set to 30°C/h. When the temperature of the coil reaches 230°C, it is kept for 3 hours, and the quenching and tempering of the coil is completed, and the expected mechanical properties are achieved. At this time, the residual oil is also volatilized, but it has not entered the dangerous temperature range of oil spots (245 ° C ~ 400 ° C);

In the fourth stage, the furnace gas is set to 0°C, and the side cooling fan is started to quickly cool down. When the metal temperature drops below 150°C, it is out of the furnace and exposed to air.

| Si | Fe | Cu | Mn | Mg | Cr | Ti | Al |

| 0.1 | 0.2~0.3 | 0.05 | 0.08 | 2.5~2.7 | 0.18~0.24 | 0.01~0.03 | Remainder |

1) Si in the alloy is an impurity element. During casting and solidification, it can form complex ternary compounds with Fe and Al. The primary phase has a large size and is distributed on the dendrite boundary. It is an insoluble phase during the melting process, which is harmful to the plasticity of the alloy . Strict control of w(Si)≤0.10% in the test can reduce the overall amount of AlFeSi complex ternary compounds, thereby improving the plasticity of the alloy.

2) Fe in the alloy is not all impurity elements, and its mass fraction is controlled at 0.2% to 0.3%, which can avoid its harmful effects and play its beneficial role. Part of the Fe element in the alloy exists in a supersaturated form. During the homogenization process at high temperature, the AlFeSi dispersed phase can be precipitated inside the grain, and its size is very small, which can refine the recrystallized grain and contribute to the strength and plasticity.

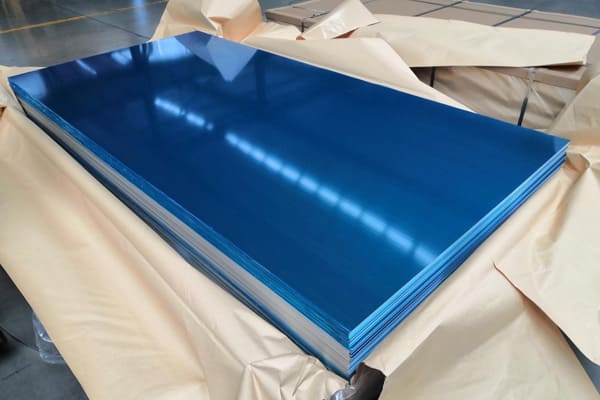

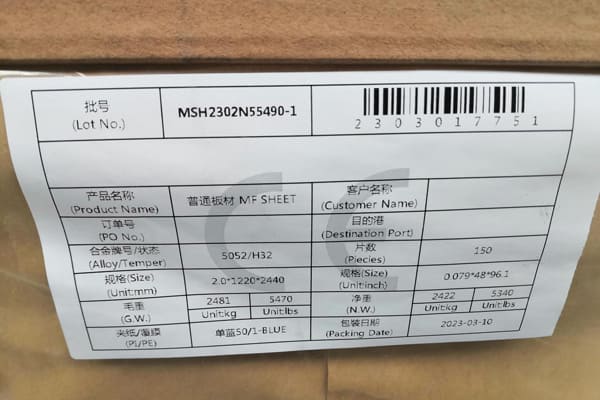

Packaged 5052-H32 Aluminum Sheet

3) In the alloy, w(Fe)/w(Si)>2.0 is controlled, and the α phase (AlFeSi) and a small amount of β phase (AlFeSi) are mainly formed during solidification, and the morphology of the α phase is bone-like. It can be fully broken during the rolling process and is harmless to plasticity. The β phase (AlFeSi) is a needle-like hard and brittle phase, which is difficult to break during hot rolling and is harmful to plasticity.

4) Cu in the alloy is an impurity element, which has an impact on the corrosion resistance of the alloy. The w(Cu) is controlled to be no more than 0.05%.

5) Mn in the alloy is an impurity element. For 5052 aluminum alloy, Cr is used to refine the recrystallized grains, not Mn, so w(Mn) should be controlled within 0.08%.

6) Mg in the alloy is an alloying element, and Mg is dissolved in the aluminum matrix, which can hinder the movement of dislocations and play a role in work hardening. Controlling w(Mg) at 2.5% to 2.7% can ensure a faster work hardening effect, and sufficient tensile strength can be guaranteed without a large cold working rate.

7) Cr in the alloy is an alloying element. It exists in a supersaturated form when the ingot is solidified, and it precipitates during the subsequent heating process to form a dispersed phase CrAl7. The particles have good thermal stability and can refine the recrystallized grains. It can improve the strength and plasticity of the alloy. Control w(Cr) at 0.18% to 0.24%. If the chromium content is too high, a harmful coarse phase will be formed; if the chromium content is too low, the dispersed phase will be insufficient and the beneficial effect will be weakened.

8) Ti in the alloy can form TiAl3 and AlTi5B1, which can refine the grains of the ingot, thereby improving the mechanical properties of the ingot.

1) The coil produced by the new process has good surface quality, no oil spots and residual oil, and meets the requirements of the standard. Internal structure observation: the crystal grains are fine and uniform, without fibrous structure. The anisotropy of this organizational state is small, and it is not easy to crack when bent. However, the conventional hot-rolled low-temperature directly off-line products are fibrous structures with large anisotropy, and the plates are prone to cracking when they are bent transversely.

2) The mechanical properties and bending test results of the 5.0mm thick 5052-H32 aluminum alloy plate produced by the new process are shown in Table 4. The plates were sent to the end users for trial use. The results were good, and the 90°0t bending did not crack. The new craft products reached the predetermined target requirements.

2Mm Thickness 5052-H32 Aluminum Sheet

Honeycomb aluminum foil, also known as aluminum honeycomb core, is a type of lightweight core material made from two layers of aluminum foil that are bonded together in a way that creates a series of hexagonal cells, much like a honeycomb.

Compared with other alloy foils of series 1, such as 1060 and 1070 aluminum foils, the content of (Fe+Si) in 1100 aluminum foil is higher than both, and the content of Fe is the key factor to improve the strength and toughness

Our embossed aluminum foil products are exported to more than 60 countries and regions in the European Union, the Middle East, Southeast Asia, and South America, and enjoy a good reputation in the international market with the best service and high-quality products.

Heavy duty aluminum foil provides extra strength and tear resistance. Many cooks use it for baking, grilling, and storage. Most foil rolls marked "heavy duty" are between 0.0008" and 0.001" thick, which is roughly 0.02032-0.0254mm in national units

3004 Aluminum Sheet is a medium-strength aluminum alloy with manganese and magnesium as the main alloying elements. Its strength is higher than 3003 Aluminum Sheet, but the ductility is lower.

Our 3003 Aluminum foil products have been exported to Australia, Morocco, Syria, Kuwait, Turkey, Saudi Arabia, UAE, Iraq, Jordan, Germany, Poland, Spain, Brazil, etc. We sincerely welcome you to visit our factory.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

Dear Sir, Please offer your best FOB Prices specs are as under ALUMINIUM STRIP (AL=99.50% MIN) SIZE:450 X32 X6 MM. DIN EN 570 EN-AW 1050 A, QUANTITY=3400KG

Hello, Would you be so kind to offer item as follows: Coil 0,6х1250 (1000)mm EN AW-3105 5tons

Hello, Can you offer me Aluminium plates? Actally I need: 110mm x 1700mm x 1700mm 5083 H111 - 21 pcs Next year planed is 177 pcs

Świetny artykuł. Byłem zachwycony, że wyszukałem ten artykuł. Wielu osobom wydaje się, że mają rzetelną wiedzę na ten temat, ale często tak nie jest. Stąd też moje miłe zaskoczenie. Jestem pod wrażeniem. Zdecydowanie będę rekomendował to miejsce i częściej wpadał, aby zobaczyć nowe rzeczy.

requirement of aluminium strip