This comprehensive guide not only provides a detailed comparison between 5052 H32 vs H34 aluminum plates but also positions these materials within the broader context of aluminum alloys, ensuring readers understand their value and potential in various industries.

5052 aluminum alloy is one of the most versatile and widely used aluminum alloys, known for its excellent corrosion resistance, good workability, and high strength-to-weight ratio. It’s particularly popular in applications requiring high fatigue strength and moderate to high corrosion resistance. This article will provide an in-depth comparison between 5052 H32 and H34 aluminum plates, focusing on their differences in temper, mechanical properties, applications, and unique characteristics.

5052 H32 vs H34 Aluminum Plates

Composition:

5052 aluminum is an aluminum-magnesium alloy, with the following typical composition:

General Properties:

| Property | 5052 H32 | 5052 H34 |

| Tensile Strength (MPa) | 215 – 265 | 230 – 280 |

| Yield Strength (MPa) | 160 – 215 | 180 – 230 |

| Elongation (%) | 10 – 12 | 8 – 10 |

| Hardness (Brinell) | 60 – 70 | 65 – 75 |

| Density (g/cm³) | 2.68 | 2.68 |

| Elastic Modulus (GPa) | 70 | 70 |

| Thermal Conductivity (W/m-K) | 138 | 138 |

5052 H32 Aluminum Plates Sheet Metal Work

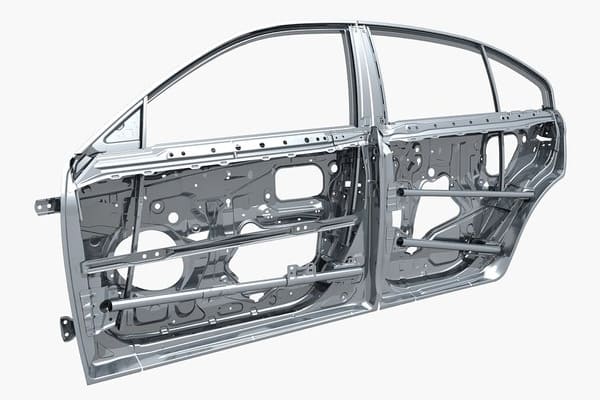

5052 H34 for Auto

Q: Which temper is better for bending?

A: H32 is generally better for bending due to its slightly higher elongation and lower strength.

Q: Can 5052 H32 and H34 be welded together?

A: Yes, both tempers can be welded together, but the strength of the weld will be closer to that of the lower temper (H32).

Q: Is there a significant cost difference between H32 and H34?

A: Typically, H34 might be slightly more expensive due to the additional work hardening process, but this can vary based on market conditions and supplier pricing.

Q: How does 5052 compare to other aluminum alloys in terms of corrosion resistance?

A: 5052 has one of the best corrosion resistances among aluminum alloys, particularly in marine environments, surpassed only by alloys like 5083 and 5086.

Q: Can 5052 aluminum plates be painted?

A: Yes, 5052 aluminum can be painted, but proper surface preparation and primer application are crucial for adhesion and durability.

5052 H32 vs H34 aluminum plates offer distinct advantages depending on the application’s requirements. While H32 provides better formability and is often preferred for applications where bending and shaping are involved, H34’s slightly higher strength makes it suitable for applications where durability and resistance to deformation are paramount. Both tempers share the inherent advantages of the 5052 alloy, including excellent corrosion resistance, good workability, and high strength-to-weight ratio, making them invaluable in industries ranging from marine to automotive, and from construction to electronics.

This comprehensive guide not only provides a detailed comparison between 5052 H32 vs H34 aluminum plates but also positions these materials within the broader context of aluminum alloys, ensuring readers understand their value and potential in various industries.

If you are looking for top-quality prepainted aluminum coils with various alloy models and specifications, Huawei Aluminum is your ultimate choice.

5754 aluminum sheet has the characteristics of excellent processability, good corrosion resistance, weldability and easy forming. As a wrought alloy, 5754 aluminum sheet can be formed by rolling, extrusion, and forging, but not by casting.

3004 aluminum coil is an aluminum-manganese alloy, which is the most widely used anti-rust aluminum. The strength of this alloy is not high. It is similar to 3003 alloys with about 1% magnesium added.

1060 Aluminum Coil is composed of 99.6% aluminum, which is similar to the 1050 alloy of the same family, but the aluminum content differs by 0.1%.

Huawei Aluminum is a high-quality 8079 aluminum foil manufacturer. It has multiple advantages in the production of 8079 aluminum foil. Its aluminum foil products are deeply loved by customers at home and abroad.

Aluminum strip for transformer means that aluminum strip is used as conductive material in the high and low voltage windings of dry-type transformers and oil-immersed transformers.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

Dear Sir, Please offer your best FOB Prices specs are as under ALUMINIUM STRIP (AL=99.50% MIN) SIZE:450 X32 X6 MM. DIN EN 570 EN-AW 1050 A, QUANTITY=3400KG

Hello, Would you be so kind to offer item as follows: Coil 0,6х1250 (1000)mm EN AW-3105 5tons

Hello, Can you offer me Aluminium plates? Actally I need: 110mm x 1700mm x 1700mm 5083 H111 - 21 pcs Next year planed is 177 pcs

Świetny artykuł. Byłem zachwycony, że wyszukałem ten artykuł. Wielu osobom wydaje się, że mają rzetelną wiedzę na ten temat, ale często tak nie jest. Stąd też moje miłe zaskoczenie. Jestem pod wrażeniem. Zdecydowanie będę rekomendował to miejsce i częściej wpadał, aby zobaczyć nowe rzeczy.

requirement of aluminium strip