Aluminum alloy material, as a metal material alloyed with aluminum and other elements (such as copper, magnesium, manganese, silicon, zinc, etc.), is used in industrial production and daily life due to its unique physical and chemical properties and excellent performance.

Aluminum alloy material, as a metal material alloyed with aluminum and other elements (such as copper, magnesium, manganese, silicon, zinc, etc.), is used in industrial production and daily life due to its unique physical and chemical properties and excellent performance. plays an important role. This article will introduce the characteristics of aluminum alloy in detail and explore its wide range of applications in various fields.

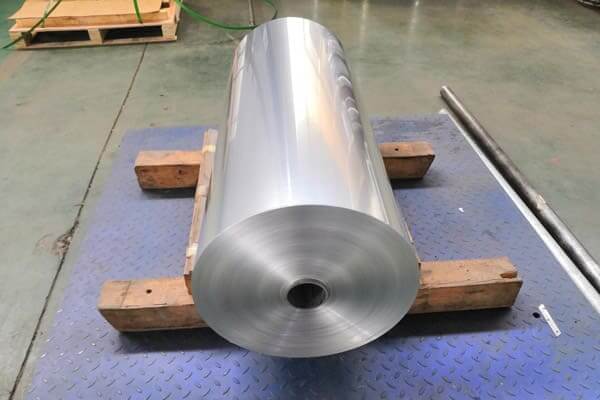

Aluminum alloy materials

Common aluminum alloy alloys cover multiple series. Here are some major aluminum alloy series and typical alloys:

1000 series aluminum: series with higher pure aluminum content, such as 1050, 1060, etc., mainly used in occasions with high requirements on conductivity and corrosion resistance, such as cables, foils, and chemical equipment linings.

2000 series: Duralumin alloys with copper as the main alloy element, such as 2014 and 2024, have high strength properties and are widely used in aerospace, rail transit structural parts and sports equipment manufacturing.

3000 series: Added manganese as the main alloy element, such as 3003 and 3004, which have good anti-rust properties and are commonly used in containers, pipes, automobile radiators, building materials and other fields.

3000 series aluminum alloy sheet

5000 series: Mainly containing magnesium, such as 5052, 5083, and 5754. These alloys have high corrosion resistance and weldability, and are mostly used in ships, vehicles, pressure vessels, and building curtain wall systems.

6000 series: With magnesium and silicon as the main alloy elements, such as 6061, 6063, and 6082, it is one of the most widely used aluminum alloy series. It has moderate strength and excellent processability. It is suitable for various industrial profiles, pipes, wires, and precision parts. It is commonly used in building door and window frames, aircraft structural components, bicycle racks and other products.

7000 series: High-strength aluminum alloys, such as 7075, contain zinc as the main alloy element. They have the highest strength but relatively low corrosion resistance. They are mainly used in advanced structural components, racing parts and high-end sports equipment in the aviation industry.

Aluminum alloy materials are ubiquitous in life, and aluminum alloy products exist in various forms. The following is an introduction to you.

Aluminum foil material

Huawei Aluminum specializes in the production and sales of aluminum plates/rolls, aluminum foil, aluminum wafers and other materials. Our products are customized by customers and the price is excellent. If you have any needs, please contact us.

1050 aluminum alloy: This is a kind of industrial pure aluminum with high purity. Its aluminum content is usually more than 99.5%, and it has good electrical conductivity and corrosion resistance. It is mainly used in manufacturing applications that do not require high strength but require high electrical or thermal conductivity, such as shielding layers of power cables, electronic foils, and aluminum foil for food packaging. 1050 aluminum alloy can be made into sheets or foils of different thicknesses and maintains good formability after O-state (fully annealed) treatment.

3003 aluminum alloy: This series of aluminum alloy materials contains a small amount of manganese, which gives it good mechanical properties and corrosion resistance. It is a commonly used anti-rust aluminum alloy. It is suitable for making tanks, car radiators, household kitchenware and other parts that require both lightweight and corrosion resistance. 3003 aluminum sheet plate can be cold rolled into plates of different thicknesses or extruded into profiles of various cross-sectional shapes. The status codes include H14 (semi-hard), H16 (medium hardness), H18 (fully soft), etc., and different tempering states Corresponding to different molding and use requirements.

5052 aluminum alloy: This alloy contains magnesium and is a typical rust-proof aluminum alloy with high strength and excellent weldability. It is suitable for use in high-strength corrosion-resistant fields such as ships, vehicles, and containers, as well as complex structural parts such as pressure vessels and aerospace components. 5052 aluminum alloy materials is often processed into thick or medium-thick plates. The states include H32 (solid solution + slight incomplete annealing), H34 (further annealing to increase toughness) and H38 (higher degree of annealing to improve ductility), depending on the final product. Select the corresponding state according to the mechanical performance requirements.

6061 aluminum alloy: Belongs to the 6xxx series. It mainly adds silicon and magnesium. It can be strengthened after heat treatment, so it has high mechanical strength and good corrosion resistance. It is widely used in building structures, bridges, bicycle frames, aerospace parts and other fields. 6061 aluminum alloy products can be in T6 state (solid solution + artificial aging treatment). In this state, the material reaches the best balance of mechanical properties. Its size specifications can be customized according to design requirements, and can be produced from thin plates to thick-walled pipes.

7075 aluminum alloy: This ultra-high-strength aluminum alloy contains zinc and magnesium and is known as an “aerospace-grade” aluminum alloy with extremely high strength and hardness. It is mainly used in aircraft structural parts, high-end sports equipment, precision mechanical parts and other application scenarios that require extremely high strength to weight ratio. 7075 aluminum alloy materials is generally processed through T6 or T73/T76 conditions to obtain the best mechanical properties. Its products are in various forms, covering thin plates, thick plates, bars, forgings, etc.

1050 Aluminum Coil belongs to the commercially pure wrought 1000 series of alloys with a purity of 99.5% aluminum. This alloy is usually used for cold rolling or extrusion. It has the characteristics of high plasticity, corrosion resistance, electrical conductivity, and thermal conductivity.

The 3003 aluminium strip is made of 3003 aluminium alloy. The 3 series aluminum alloy is also called an aluminum-manganese alloy.

Our commitment to quality, variety, and customization ensures that you'll find the perfect insulation aluminum coil for your project.

3004 aluminum coil is an aluminum-manganese alloy, which is the most widely used anti-rust aluminum. The strength of this alloy is not high. It is similar to 3003 alloys with about 1% magnesium added.

6061 aluminum coil" is an aluminum alloy that is commonly used for applications such as automotive and aerospace components, as well as for construction and industrial products. This article will explore the Properties,Benefits and Applications of 6061 aluminum coil, from its raw material form to the finished product.

3mm aluminum sheet refers to an aluminum sheet with a thickness of 3mm, and 3mm is a common thickness of aluminum sheet

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

Dear Sir, Please offer your best FOB Prices specs are as under ALUMINIUM STRIP (AL=99.50% MIN) SIZE:450 X32 X6 MM. DIN EN 570 EN-AW 1050 A, QUANTITY=3400KG

Hello, Would you be so kind to offer item as follows: Coil 0,6х1250 (1000)mm EN AW-3105 5tons

Hello, Can you offer me Aluminium plates? Actally I need: 110mm x 1700mm x 1700mm 5083 H111 - 21 pcs Next year planed is 177 pcs

Świetny artykuł. Byłem zachwycony, że wyszukałem ten artykuł. Wielu osobom wydaje się, że mają rzetelną wiedzę na ten temat, ale często tak nie jest. Stąd też moje miłe zaskoczenie. Jestem pod wrażeniem. Zdecydowanie będę rekomendował to miejsce i częściej wpadał, aby zobaczyć nowe rzeczy.

requirement of aluminium strip