Aluminum Plates for Floor Radiant Heating has revolutionized home comfort by providing an even, silent, and efficient heating solution. Central to this system's effectiveness are aluminum plates, which play a pivotal role in heat distribution and system efficiency.

Aluminum Plates for Floor Radiant Heating has revolutionized home comfort by providing an even, silent, and efficient heating solution. Central to this system’s effectiveness are aluminum plates, which play a pivotal role in heat distribution and system efficiency. This article delves deeper into why aluminum plates are the preferred choice for radiant floor heating, exploring their specifications, applications, benefits, and providing insights for those considering this heating method.

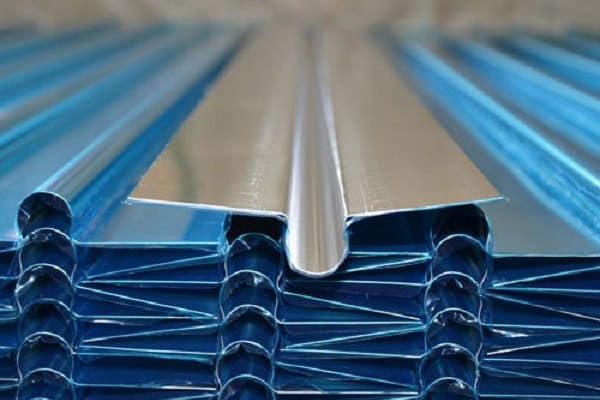

Aluminum heat transfer plate

Aluminum Radiant Heat Transfer Plates are integral to radiant floor heating systems for several reasons:

Table 1: Key Properties of Aluminum Plates for Radiant Heating

| Property | Description |

| Thermal Conductivity | 237 W/mK, significantly higher than other materials like steel or plastic |

| Corrosion Resistance | Excellent, extending the life of the heating system |

| Weight | Lightweight, reducing structural load and simplifying installation |

| Cost Efficiency | Offers a good balance between cost and performance |

| Sustainability | Recyclable, aligning with green building practices |

| Versatility | Compatible with various floor types and installation methods |

Application of aluminum heat transfer plate

Table 2: Comparison of Aluminum Plates with Other Materials

| Material | Advantages | Disadvantages |

| Aluminum | High thermal conductivity, lightweight, cost-effective, durable | Slightly less conductive than copper |

| Copper | Superior thermal conductivity | Expensive, heavier, more labor-intensive to install |

| Steel | Durable, but less efficient in heat transfer | Heavier, slower heat-up time, susceptible to rust |

| Plastic/Composite | Low cost, lightweight | Poor thermal conductivity, less durable, prone to degradation over time |

Aluminum Plates for Floor Radiant Heating

When considering aluminum plates for your radiant floor heating system, your RFQ should include:

Aluminum plates are an essential component in modern radiant floor heating systems, offering unparalleled benefits in terms of efficiency, comfort, and sustainability. Their ability to evenly distribute heat, reduce energy costs, and provide long-term durability makes them a wise investment for both residential and commercial applications. For those looking to install or upgrade to radiant floor heating, understanding the role of aluminum plates, their specifications, and how to specify them in an RFQ will ensure you get the most out of this heating technology.

For the latest prices, specifications, or to place an order, contact reputable suppliers, ensuring that your radiant heating project aligns with your comfort, efficiency, and environmental goals.

3004 Aluminum Sheet is a medium-strength aluminum alloy with manganese and magnesium as the main alloying elements. Its strength is higher than 3003 Aluminum Sheet, but the ductility is lower.

The market price of 1235 aluminum foil is relatively cheap, and it has become one of the most popular products on the market. It is a common household aluminum foil that can be used as food flexible packaging foil.

Aircraft Grade Aluminum Sheet Plate is an alloy that has undergone special treatment such as high-temperature oxidation, and can withstand thousands of degrees of high temperature or strong impact.

If you are looking for top-quality prepainted aluminum coils with various alloy models and specifications, Huawei Aluminum is your ultimate choice.

Our commitment to quality, variety, and customization ensures that you'll find the perfect insulation aluminum coil for your project.

6061 aluminum sheet is an al-si-mg alloy that has been strengthened by precipitation hardening. 6061 aluminum has a high strength-to-weight ratio, above-average corrosion resistance, good machinability, and is well suited for welding.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

Dear Sir, Please offer your best FOB Prices specs are as under ALUMINIUM STRIP (AL=99.50% MIN) SIZE:450 X32 X6 MM. DIN EN 570 EN-AW 1050 A, QUANTITY=3400KG

Hello, Would you be so kind to offer item as follows: Coil 0,6х1250 (1000)mm EN AW-3105 5tons

Hello, Can you offer me Aluminium plates? Actally I need: 110mm x 1700mm x 1700mm 5083 H111 - 21 pcs Next year planed is 177 pcs

Świetny artykuł. Byłem zachwycony, że wyszukałem ten artykuł. Wielu osobom wydaje się, że mają rzetelną wiedzę na ten temat, ale często tak nie jest. Stąd też moje miłe zaskoczenie. Jestem pod wrażeniem. Zdecydowanie będę rekomendował to miejsce i częściej wpadał, aby zobaczyć nowe rzeczy.

requirement of aluminium strip