Aluminum alloys are widely used in daily life due to their high strength, low density and strong corrosion resistance. However, there are many types of aluminum alloys.

Aluminum alloys are widely used in daily life due to their high strength, low density and strong corrosion resistance. However, there are many types of aluminum alloys. They can be classified into cast aluminum alloys, deformed aluminum alloys, forged aluminum alloys, extruded aluminum alloys and rolled aluminum alloys based on processing technology alone.

Classification of aluminum alloys according to processing technology

The following is a detailed explanation of aluminum alloys with various processing technologies:

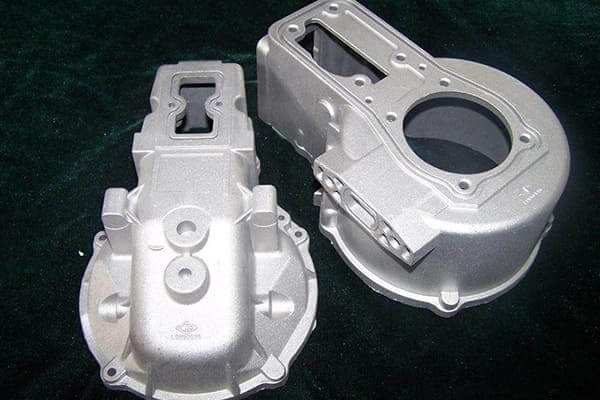

Cast aluminum alloy: an aluminum alloy material that is directly injected into a mold by cooling and solidifying the molten aluminum alloy liquid after smelting. This type of aluminum alloy has good casting properties and specific mechanical properties, and is suitable for parts with complex shapes that are difficult to manufacture by forging or extrusion. Common cast aluminum alloys include aluminum silicon alloys, aluminum copper alloys, etc.

Deformed aluminum alloy: refers to an aluminum alloy that can be plastically deformed by pressure processing (such as rolling, extrusion, forging, etc.) without destroying its basic properties. Deformed aluminum alloys can be further divided into:

Forged aluminum alloy: a type of deformed aluminum alloy, specifically refers to aluminum alloy products processed by forging technology, with higher mechanical properties and finer grain structure, suitable for important parts requiring high strength and high toughness, such as aircraft landing gear, engine parts, etc.

Extruded aluminum alloy: after the aluminum alloy is heated to a plastic state by an extruder, it is forced through a die of a specific shape, and after cooling, aluminum alloy profiles of various cross-sectional shapes are obtained. This process is widely used in construction, transportation, electrical equipment and other fields, such as door and window frames, radiators, rail vehicle structural parts, etc.

Aluminum alloy rolling process

Rolled aluminum alloy: Aluminum alloy slabs are rolled through a rolling mill multiple times to form thinner sheets, strips or foils. These aluminum alloy products have a smooth surface and precise dimensions and are suitable for packaging, building cladding, electronic product housings and other fields.

Each processing technology gives aluminum alloy different physical, chemical and mechanical properties to meet the specific needs of different industries and products. If you need aluminum alloy products, please contact us, our professional salesperson will recommend the most suitable aluminum alloy for you according to your needs.Email: [email protected]

Cold rolled aluminum strip is a thin strip made of aluminum alloy that is processed by cold rolling. It is widely used in aerospace, automobile manufacturing, building materials and other fields.

As one of the main aluminium circle manufacturers in the Chinese market, our aluminium circle are made with the best raw materials and machinery, the main products include 1000 series, 3000 series, 5000 series and 8000 series, with an output of more than 5000 tons/month

5454 aluminum sheet has strong anti-rust ability and belongs to the 5000 series aluminum-magnesium alloy. 5454 aluminum sheet is also a non-heat treatable alloy and is 20% stronger than 5052 aluminum sheet. It is often used in marine facilities pipelines, aluminum tank car bodies and other fields.

Food packaging, household foil raw material 3004 aluminum foil, professional aluminum alloy production expert, 20 production lines

Aluminum foil containers made of aluminum foil can be processed into various shapes, common alloys are 8011, 3003, 3004, 5052 aluminum foil.

3004 aluminum coil is an aluminum-manganese alloy, which is the most widely used anti-rust aluminum. The strength of this alloy is not high. It is similar to 3003 alloys with about 1% magnesium added.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

Dear Sir, Please offer your best FOB Prices specs are as under ALUMINIUM STRIP (AL=99.50% MIN) SIZE:450 X32 X6 MM. DIN EN 570 EN-AW 1050 A, QUANTITY=3400KG

Hello, Would you be so kind to offer item as follows: Coil 0,6х1250 (1000)mm EN AW-3105 5tons

Hello, Can you offer me Aluminium plates? Actally I need: 110mm x 1700mm x 1700mm 5083 H111 - 21 pcs Next year planed is 177 pcs

Świetny artykuł. Byłem zachwycony, że wyszukałem ten artykuł. Wielu osobom wydaje się, że mają rzetelną wiedzę na ten temat, ale często tak nie jest. Stąd też moje miłe zaskoczenie. Jestem pod wrażeniem. Zdecydowanie będę rekomendował to miejsce i częściej wpadał, aby zobaczyć nowe rzeczy.

requirement of aluminium strip