As one of the main aluminium circle manufacturers in the Chinese market, our aluminium circle are made with the best raw materials and machinery, the main products include 1000 series, 3000 series, 5000 series and 8000 series, with an output of more than 5000 tons/month

Aluminium circle, AKA aluminum disc, aluminum disk, and aluminum wafer, is one of the deep-processed products of aluminum sheet.It is named after the shape of the circular aluminum plate.

1060 aluminum disc is a relatively low-strength, high-purity alloy with a minimum aluminum content of 99.6%. It is one of the most widely used and relatively inexpensive alloys on the market.

It is known for its excellent welding characteristics, high flexibility, corrosion resistance, good electrical and thermal conductivity.

Aluminium 1060 Circles Supplier

We are the original factory of aluminium coils, sheets and circles in China, we will use the best quality and service to meet our customer requirements.

In terms of 1060 aluminum circles products, what advantages do we have?

1. Complete specifications. In addition to regular sizes, the thinnest 0.2mm and the thickest 10mm platters are available;

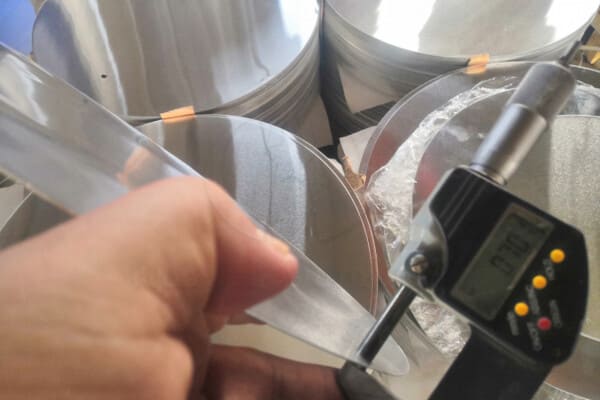

2. Good surface performance, bright without obvious scratches, ensuring no oil stains, oxidation, black spots, etc.;

3. When the thickness is greater than 0.5mm, ensure that the edges of the finished product are neat and free of burrs;

4. In the early stage, the particle size grade and elongation rate of the coil are well controlled, which ensures the excellent deep drawing and spinning performance of the disc.

This control require also effectively avoids the occurrence possibility of bad patterns in the customer’s later processing, such as wire drawing, ruffles, high ear rate, etc. ;

1060 aluminium circle

5. Strictly control the alloy, state and performance of the coil to ensure the accuracy and diversity of the provided circles performance parameters;

6. The introduction of advanced and efficient production equipment has improved the cycle production efficiency and material utilization rate, and effectively shortened the production cycle;

7. According to the different purposes and requirements of customers, provide customers with professional purchase suggestions to ensure that the correct alloy, state, etc. are selected to reduce customer costs;

8. The product packaging is firm, in line with domestic sales and international export standards.

1060 Aluminum Circle package

|

Product Name

|

1060 Aluminum Circle

|

|

Material

|

aluminum

|

|

Thickness

|

0.2~10mm

|

|

width

|

70~1550mm

|

|

Technique

|

Hot rolled,cold rolled,forging,casting,etc

|

|

Packing

|

standard export packing:wooden pallet + paperboard + stell strip

|

|

surface treatment

|

Anodized,brushed,polished,mill finished,power coated,sand blast.

|

|

Lead time

|

30 days after prepayment.

|

|

Payment

|

30% T/T in advance, balance against B/L copy.

|

|

MOQ

|

5MT

|

|

Application

|

cooking utensils, cookware, kitchenware, panel, signboard, etc.

|

| chemical composition(%) | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | —— | 0.05 | 0.03 | 99.6 |

Hot Rolled Half Hard Aluminum Circle 1060

1. Prepare the master alloys

2. Melting furnace :put the alloys into the melting furnance

3. D.C.cast aluminum ingot:To made the mother ingot

1050 1060 aluminium circle production line

4. Mill the aluminum ingot:to make the surface and side smooth

5. Heating furnnace

6. Hot rolling mill:made the mother coil

7. Colding rolling mill:the mother coil was rolled as the thickness you want to buy

8. Punching process:become the size what you want

9. Annealing furnace:change the temper

10. Final inspection

11. Packing:wooden case or wooden pallet

12. Delivery

Because the 1060 aluminium disc possesses good ductility, so there is a little tolerance after the annealing. You can see the differences in the form below.

| Nominal Diameter | Tolerance |

| Multiple of 5mm | +/- 0.5mm |

| Not multiple of 5mm | +/- 3.0mm |

| Temper | Definition |

| O | Annealed |

| H12 | Strain Hardened, 1/4 Hard |

| H14 | Strain Hardened, 1/2 Hard |

| H16 | Strain Hardened, 3/4 Hard |

| H18 | Strain Hardened, Full Hard |

| H22 | Strain Hardened and Partially Annealed, 1/4 Hard |

| H24 | Strain Hardened and Partially Annealed, 1/2 Hard |

| H26 | Strain Hardened and Partially Annealed, 3/4 Hard |

| H28 | Strain Hardened and Partially Annealed, Full Hard |

Huawei Aluminum’s 1060 aluminium circle packaging meets international export standards and can also be covered with plastic film and kraft paper according to customer needs.

We use wooden boxes or wooden pallets to protect the products from damage during transportation. There are usually two kinds of packages, one is eye-to-wall and the other is eye-to-sky, and customers can choose any one of them.

Generally speaking, a pack of 2 tons, 1×20′ container is loaded with 18-22 tons, and 1×40′ container is loaded with 20-24 tons.

Aluminium Circle Packing

As one of the main aluminium circle manufacturers in the Chinese market, our aluminium circle are made with the best raw materials and machinery, the main products include 1000 series, 3000 series, 5000 series and 8000 series, with an output of more than 5000 tons/month

After more than 20 years of development, we have accumulated customers in more than 60 countries around the world.

such as Burundi, Comoros, Burkina Faso, Djibouti, Eritrea, Ethiopia, Kenya, Madagascar, Malawi, Mauritius, Mozambique, Rwanda, Somalia, Italy, Germany, Netherlands , Bulgaria, Brazil, Chile, Thailand, Vietnam, Ghana, Malaysia, Singapore, Saudi Arabia, Israel, etc.

We use the pure aluminum ingots to manufacture 5mm aluminum sheets. They come in various widths and tempers. They are not only suitable for marine grade, but also for automobile manufacturing, pressure vessels, including water tanks, oil tanks, and the maximum width we can produce is 3000mm.

Huawei Aluminum is a large-scale 5052 aluminum foil raw material manufacturer, with 30 years of experience in aluminum foil production and sales.

5086 aluminum sheet is a high-strength, corrosion-resistant al-mg alloy, widely used in aerospace, transportation, architectural decoration and other fields.

3003 curtain wall aluminum sheet is the outer wall of a building. It is a lightweight wall of large high-rise buildings and has a certain decorative effect.

Corrosion Resistant Black Aluminum Foil for Sale, China Aluminum Foil Manufacturer Low Price Promotion, Color Coated Aluminum Foil Anodized Foil Raw Material Supplier

6061 aluminum sheet is an al-si-mg alloy that has been strengthened by precipitation hardening. 6061 aluminum has a high strength-to-weight ratio, above-average corrosion resistance, good machinability, and is well suited for welding.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

Our required qty: Aluminium Sheet in coil (620mm X 1.20mm) Qty: 200 MT. Can you give me the number of contact urgently. Thanks Matiur Rahman Director of Technical Sales dept.

Bonjour ; Nous sommes une compagnie de spectacle de rue " compagnie carabosse " nous travaillons avec la flamme . nous sommes à la recherche de tôle reflecteur en aluminium pour pouvoir crée un nouvelle objet à base d'un fil métal enflammé liquide éthanol d' une hauteur environ 1 m . Quels produits avez vous à nous proposez ? Cordialement Fabrice

Hello, I am interested in 3*1500*3500 mm 5754 H111 Checkered Aluminium Plate - Diamond Shape Powermaster Ltd. Moscow, Volokolamskoe shosse 1, str. 1, of. 19, Moscow, 125080

Buenos días, Me interesaría saber el costo de Paneles de nido de abeja de aluminio para usar como refuerzo interior de bandejas, estantes , mesadas que realizamos en acero inoxidable AISI 304. De espesor del panel de 10 y 20 mm, con la piel superior e inferior de aluminio espesor 0.8 mm liso o cepillado o solo el núcleo del nido de abeja de aluminio; con tamaño de celda de 10 o 15 mm ( o estándar ) . tamaño de las planchas de 1500 x 3000 mm o la lo que recomiende para el uso que le quiero dar. Desde ya muchas gracias

Proszę o ofertę na blachę aluminiową grubość 20 mm, w gatunku 1060. 8000 kg