Aluminum foil refers to thin strips of aluminum and aluminum alloys with a thickness of ≤0.2mm. Since aluminum is soft, ductile and has a silvery luster, if the rolled sheets are mounted on offset paper with sodium silicate and other substances It is made into aluminum foil sheets and can also be printed. Aluminum foil is generally classified according to thickness, status and use.

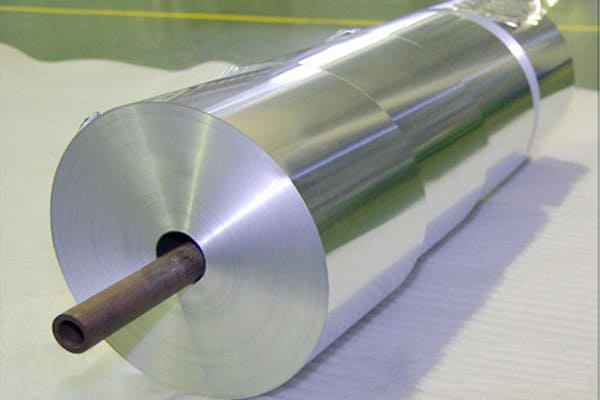

Aluminum Foil Jumbo Roll

Heavy-duty aluminum foil generally refers to aluminum foil products that are thicker and stronger than standard household aluminum foil. The thickness of standard household aluminum foil ranges from approximately 0.006 mm to 0.01 mm , while heavy-duty aluminum foil will be thicker to provide better durability and support for needs that require more In high-strength applications, such as wrapping large pieces of food during cooking, making temporary baking pans, or outdoor barbecues, it can withstand higher temperatures and heavier loads without breaking. Generally, suppliers consider aluminum foil with a thickness greater than 0.01 mm as heavy-duty aluminum foil.

Heavy Duty Aluminum Foil

Production Process

The production process of aluminum foil and heavy-duty aluminum foil is basically the same. Both aluminum foils of a certain thickness are obtained through multiple rolling processes such as casting, rough rolling, and finishing rolling, surface treatment, and winding.

Thickness comparison

The conventional thickness of aluminum foil is between 0.006-0.01mm

Heavy-duty aluminum foil generally refers to aluminum foil with a thickness greater than 0.01mm

Strength comparison

There are many factors that affect the strength of aluminum foil, such as thickness, alloy, tempers, etc. Since the thickness of heavy-duty aluminum foil is greater than that of conventional aluminum foil, the strength of heavy-duty aluminum foil is better than that of conventional aluminum foil under the same alloy and state.

Tensile strength comparison

Another difference between aluminum foil and heavy-duty aluminum foil is their tensile strength. Tensile strength is a measure of how much stress or pressure a material can withstand before breaking or tearing. Heavy-duty aluminum foil has a higher tensile strength than regular aluminum foil, which means it can withstand greater stress and pressure without tearing or breaking. This makes it ideal for applications where the foil will be under a lot of pressure, such as wrapping heavy or bulky items.

Thermal insulation performance comparison

Aluminum foil has strong thermal insulation properties, so it is often used in pipes and building insulation layers. Similarly, the thicker the aluminum foil, the better the thermal insulation effect. Therefore, the thermal insulation performance of Heavy Duty Aluminum Foil is better than that of conventional aluminum foil.

Differences Between Aluminum Foil and Heavy Duty Aluminum Foil

Cost and Application Comparison

Conventional aluminum foil is the aluminum foil we often see, while heavy-duty aluminum foil is less common. Due to the influence of technology and production efficiency, the price of heavy-duty aluminum foil is higher than that of conventional aluminum foil.

Conventional aluminum foil can basically meet our daily needs of household aluminum foil, lunch box aluminum foil, pharmaceutical packaging aluminum foil, honeycomb aluminum foil, capacitor aluminum foil and other applications. However, if there are special requirements for aluminum foil strength and thermal insulation performance, heavy-duty aluminum foil is required. Due to its special properties, heavy-duty aluminum foil can meet higher requirements, so the price of heavy-duty aluminum foil is higher than that of regular aluminum foil.

There are several key differences between regular aluminum foil and heavy-duty aluminum foil. Heavy-duty aluminum foil is thicker, stronger, and more durable than regular aluminum foil, making it better for heavy or bulky items, high-temperature cooking, and applications where durability and strength are important. Regular aluminum foil is better suited for lighter applications, such as wrapping sandwiches or covering smaller dishes, and is generally cheaper and more widely available than heavy-duty aluminum foil.

When choosing between the two, it is important to consider factors such as thickness, strength, durability, purpose, cost, availability, safety considerations, and environmental impact. By understanding these key differences, you can choose the right type of aluminum foil for your needs and ensure it is used safely and responsibly. Overall, both regular and heavy-duty aluminum foil are useful tools in the kitchen that can help make cooking, storing, and transporting food easier and more convenient.

Corrosion Resistant Black Aluminum Foil for Sale, China Aluminum Foil Manufacturer Low Price Promotion, Color Coated Aluminum Foil Anodized Foil Raw Material Supplier

3000 series aluminum alloy is an AL-MG alloy whose main components are aluminum, manganese and a small amount of other elements. It has excellent properties such as good corrosion resistance, processability and weldability.

8021 aluminium foil is a common alloy in 8000 series aluminum alloys. Common aluminum foils in 8000 series aluminum alloys include 8011 Aluminum Foil and 8079.

1070 aluminum alloy belongs to the 1000 series pure aluminum with an aluminum content of 99.7%. It is widely used in electronics, electricity, construction, aerospace and other fields.

If you are looking for top-quality prepainted aluminum coils with various alloy models and specifications, Huawei Aluminum is your ultimate choice.

Huawei Aluminum aluminum discs are widely exported to Ghana, Guatemala, Burkina Faso, Algeria, Togo, Kenya, Nigeria, South Africa, Morocco and other African countries; the United Arab Emirates, Yemen, Qatar, Kuwait, Iran, Jordan, Saudi Arabia and other Middle East nation.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

Dear Sir, Please offer your best FOB Prices specs are as under ALUMINIUM STRIP (AL=99.50% MIN) SIZE:450 X32 X6 MM. DIN EN 570 EN-AW 1050 A, QUANTITY=3400KG

Hello, Would you be so kind to offer item as follows: Coil 0,6х1250 (1000)mm EN AW-3105 5tons

Hello, Can you offer me Aluminium plates? Actally I need: 110mm x 1700mm x 1700mm 5083 H111 - 21 pcs Next year planed is 177 pcs

Świetny artykuł. Byłem zachwycony, że wyszukałem ten artykuł. Wielu osobom wydaje się, że mają rzetelną wiedzę na ten temat, ale często tak nie jest. Stąd też moje miłe zaskoczenie. Jestem pod wrażeniem. Zdecydowanie będę rekomendował to miejsce i częściej wpadał, aby zobaczyć nowe rzeczy.

requirement of aluminium strip