Aluminium is one of the world’s most used materials due to its versatility and varied benefits. It is lightweight, strong, enduring, and easy to recycle, making it the perfect choice for a variety of applications and industrial uses. Aside from its recyclability and durability, aluminium also has other key features, one of which is an excellent conductor of electricity. The conductivity means that aluminium has been widely used for electrical applications such as wiring and cables whilst also offering a more cost-effective solution for industry, home, manufacturing and transportation.

Does aluminum conduct electricity

Aluminum is known for its excellent electrical conductivity, about 61% that of copper. Its lightweight and resistance to corrosion make it ideal for various applications. Are you interested in specific uses or comparisons?

Conductivity tells you how well a metal can conduct electricity. It is a measure of a material’s tendency to conduct electrical current.

Conductivity is measured in Siemens (S) per meter (m). For aluminum, a known current is passed through the aluminum sample, and the voltage drop is measured using probes.

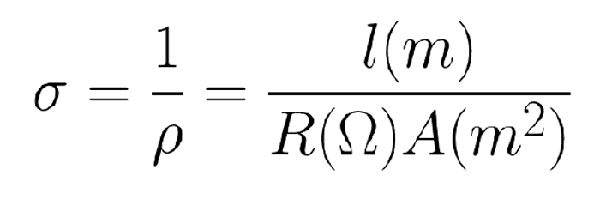

This can be used to calculate the conductivity of aluminum metal using a formula.

Conductivity calculation formula

| Rank | Metal | Electrical conductivity (Sm-1) |

| 1 | Silver | 66.7 106 |

| 2 | Copper | 64.1 106 |

| 3 | Gold | 49.0 106 |

| 4 | Aluminum | 40.8 106 |

| 5 | Rhodium | 23.3 106 |

| 6 | Zinc | 18.2 106 |

| 6 | Nickel | 16.4 106 |

| 7 | Cadmium | 14.7 106 |

| 8 | Iron | 11.2 106 |

Certain factors can affect how well a material conducts electricity. ThoughtCo explains these factors here:

The choice of surface finish for an aluminum product can have a profound effect on the electrical conductivity properties of the metal. To understand this, we need to consider the natural oxide layer that aluminum forms on its surface.

This oxide layer makes aluminum very corrosion-resistant, which is often a desired trait. However, the aluminum-oxide layer does not conduct electricity; it’s an insulator. Consider that when you apply an anodizing surface treatment to an aluminum product, the oxide layer becomes much thicker. And the consequence of anodizing is that it will electrically isolate the underlying metal.

Another typical surface finish for aluminum products is powder coating. This process confers the aluminum product with a protective and decorative layer on the surface, but it also affects electrical conductivity. The resulting product will still have some degree of conductivity, so it will not become insulated, but it won’t be as conductive as bare aluminum.

Aluminum Heat Sink

The excellent conductivity of aluminum, along with its other advantageous properties, makes it a popular choice in the electrical industry. Some key applications of aluminum in electrical systems include:

Aluminum Cable

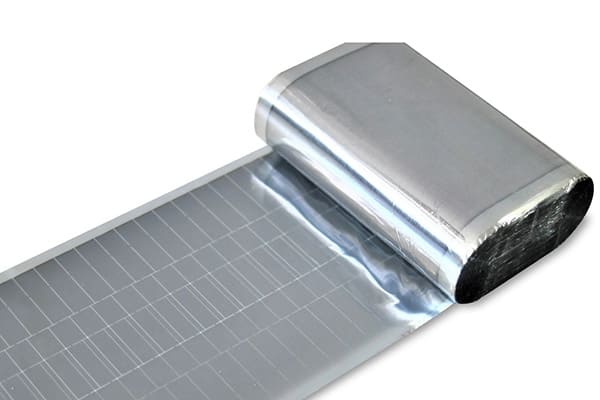

Aluminum foil for capacitors

Aluminum is a metal, and like other metals, it is a good conductor of electricity. Conductors are materials that allow current to flow through them, and insulators are materials in which current cannot easily pass through.

Steel and aluminum are both metals that are good conductors of electricity. However, aluminum has a higher electrical conductivity than steel, which means that aluminum is more conductive.

1060 aluminium strip cables have excellent load-carrying capacity, especially self-supporting capacity. An aluminum wire can be as long as 4000 meters without falling, while a copper cable can only reach 2750 meters.

5454 aluminum sheet has strong anti-rust ability and belongs to the 5000 series aluminum-magnesium alloy. 5454 aluminum sheet is also a non-heat treatable alloy and is 20% stronger than 5052 aluminum sheet. It is often used in marine facilities pipelines, aluminum tank car bodies and other fields.

3003 h14 aluminum coil refers to h14 tempered 3003 aluminum coil.And H14 tempering usually means getting 1/2 the strength with the hardness.

3105 aluminum coil is a 3000 series aluminum alloy: the main alloying addition is manganese, which is formulated for primary forming into forged products.

3003 curtain wall aluminum sheet is the outer wall of a building. It is a lightweight wall of large high-rise buildings and has a certain decorative effect.

Flexible packaging aluminum foil is a thin foil made of aluminum that is commonly used in food packaging and pharmaceutical packaging. Unlike hard aluminum foil, flexible packaging aluminum foil is soft and can adapt to various shapes of containers, so it is widely used for packaging food and medicine.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

Dear Sir, Please offer your best FOB Prices specs are as under ALUMINIUM STRIP (AL=99.50% MIN) SIZE:450 X32 X6 MM. DIN EN 570 EN-AW 1050 A, QUANTITY=3400KG

Hello, Would you be so kind to offer item as follows: Coil 0,6х1250 (1000)mm EN AW-3105 5tons

Hello, Can you offer me Aluminium plates? Actally I need: 110mm x 1700mm x 1700mm 5083 H111 - 21 pcs Next year planed is 177 pcs

Świetny artykuł. Byłem zachwycony, że wyszukałem ten artykuł. Wielu osobom wydaje się, że mają rzetelną wiedzę na ten temat, ale często tak nie jest. Stąd też moje miłe zaskoczenie. Jestem pod wrażeniem. Zdecydowanie będę rekomendował to miejsce i częściej wpadał, aby zobaczyć nowe rzeczy.

requirement of aluminium strip