The corrosion resistance of metal products refers to the property that metal materials are not prone to corrosion or oxidation reactions when they come into contact with chemical substances or the environment. Corrosion refers to the gradual loss of its original properties and forms of metals under certain environmental conditions due to the action of oxygen, water, acid, alkali or other chemical substances.

The corrosion resistance of metal products is an important performance index, especially for metal products used in harsh environments, such as marine equipment, automotive parts, building structures, piping systems, etc. The quality of corrosion resistance directly affects the service life and safety of the product.

Corrosion resistance of metals

Our common metals are iron, copper, aluminum, etc. In terms of corrosion resistance of metals, we compare them;

Under normal circumstances, the corrosion resistance of aluminum alloy is higher than that of pure aluminum.

Aluminum alloy (Aluminum Alloy) generally has good corrosion resistance. This is because a layer of aluminum oxide (Al2O3) film is naturally formed on the surface of the aluminum alloy. This oxide film has a certain degree of sealing and stability, and can effectively prevent further corrosion reactions. This characteristic makes aluminum alloys exhibit good corrosion resistance in many environments.

However, the corrosion resistance of aluminum alloys is also affected by some factors, including alloy composition, quality of oxide film, and environmental conditions. The following are some factors that affect the corrosion resistance of aluminum alloys:

How about the corrosion resistance of aluminum

Alloy composition: Different types of aluminum alloys contain different alloying elements, and the addition of these elements will affect the corrosion resistance of aluminum alloys. For example, the addition of elements such as copper and zinc may reduce the corrosion resistance of aluminum alloys, while the addition of elements such as magnesium and manganese may improve its corrosion resistance.

Oxide film quality: The quality of oxide film on the surface of aluminum alloy directly affects its corrosion resistance. A more uniform, dense and stable oxide film can better protect the base metal.

Environmental conditions: The corrosion resistance of aluminum alloys may vary under different environmental conditions. For example, aluminum alloys may have relatively poor corrosion resistance in acidic environments.

Surface treatment is an effective way to improve the corrosion resistance of aluminum alloys. The following are two common surface treatment methods for aluminum alloys:

Anodizing is a common surface treatment used to enhance the corrosion resistance, hardness and surface aesthetics of aluminum alloys. The process involves using an aluminum alloy product as an anode, and forming an oxide film on its surface through electrolysis. This oxide film is usually aluminum oxide (Al2O3), which has good sealing and corrosion resistance.

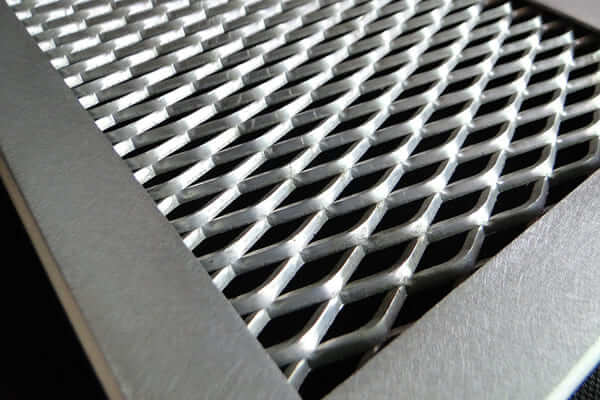

Anodized aluminum

Aluminum alloy anodizing steps:

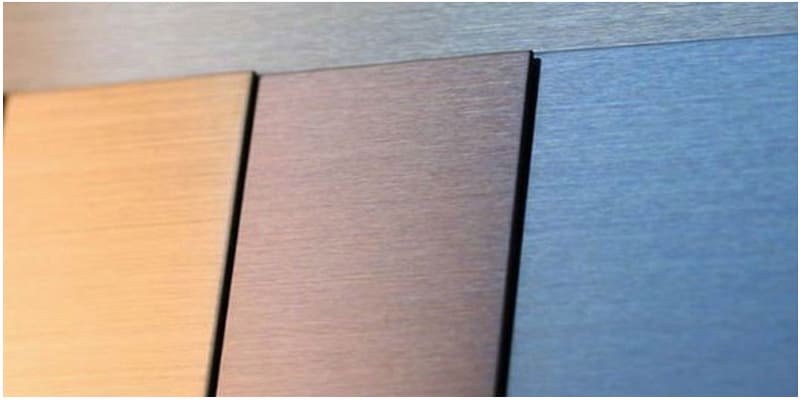

Powder coating is a surface treatment technique used to impart a corrosion-resistant, aesthetically pleasing coating to aluminum alloy products. This method is suitable for occasions where it is necessary to increase the surface hardness, wear resistance, corrosion resistance and decorative properties of aluminum alloy products. The sprayed paint is usually made of a mixture of aluminum alloy powder and resin, and different colors and textures can be selected to meet different design requirements.

Powder coated aluminum

The following are the basic steps of aluminum alloy powder coating treatment:

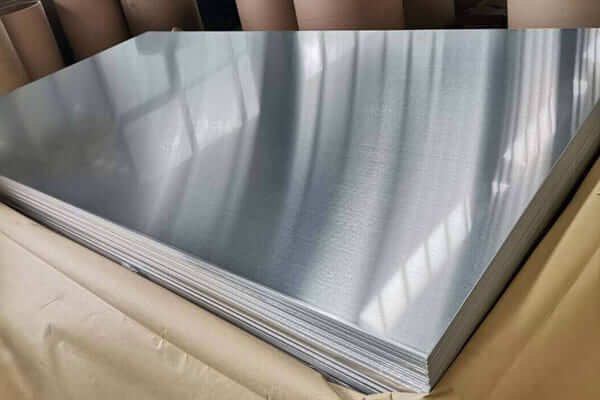

Through the explanation of the above article, we know that aluminum alloy has strong corrosion resistance, especially 5052 aluminum alloy and 6061 aluminum alloy, which are often used in shipbuilding and other fields, and are called marine-grade aluminum plates;

5052 aluminum alloy sheet

If there is a higher requirement for the corrosion resistance of aluminum alloy, surface treatment processes such as anodizing or powder coating can be carried out to improve the corrosion resistance of aluminum alloy.

The market price of 1235 aluminum foil is relatively cheap, and it has become one of the most popular products on the market. It is a common household aluminum foil that can be used as food flexible packaging foil.

5454 aluminum circles have all the properties of 5454 aluminum alloy and are often used in can sealing, non-stick pot bottoms, traffic signs, lampshades, etc.

Anodized aluminum sheet is an aluminum sheet placed in the corresponding electrolyte (such as sulfuric acid, chromic acid, oxalic acid, etc.) as an anode, and electrolysis is performed under specific conditions and the action of external current.

Cold rolled aluminum strip is a thin strip made of aluminum alloy that is processed by cold rolling. It is widely used in aerospace, automobile manufacturing, building materials and other fields.

Hydrophilic aluminum foil is obtained by coating the surface of aluminum foil with hydrophilic coating, the purpose is to improve the hydrophilic (water-attracting) performance of the aluminum foil, and it has higher heat transfer efficiency and corrosion resistance.

8006 aluminum foil is a specific alloy known for its excellent barrier properties, making it ideal for packaging applications. It provides effective protection against moisture, light, and oxygen, helping to preserve the freshness and quality of food products.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

Dear Sir, Please offer your best FOB Prices specs are as under ALUMINIUM STRIP (AL=99.50% MIN) SIZE:450 X32 X6 MM. DIN EN 570 EN-AW 1050 A, QUANTITY=3400KG

Hello, Would you be so kind to offer item as follows: Coil 0,6х1250 (1000)mm EN AW-3105 5tons

Hello, Can you offer me Aluminium plates? Actally I need: 110mm x 1700mm x 1700mm 5083 H111 - 21 pcs Next year planed is 177 pcs

Świetny artykuł. Byłem zachwycony, że wyszukałem ten artykuł. Wielu osobom wydaje się, że mają rzetelną wiedzę na ten temat, ale często tak nie jest. Stąd też moje miłe zaskoczenie. Jestem pod wrażeniem. Zdecydowanie będę rekomendował to miejsce i częściej wpadał, aby zobaczyć nowe rzeczy.

requirement of aluminium strip