Hydrophilic aluminum foil is obtained by coating the surface of aluminum foil with hydrophilic coating, the purpose is to improve the hydrophilic (water-attracting) performance of the aluminum foil, and it has higher heat transfer efficiency and corrosion resistance.

Hydrophilic Aluminum Foil is a specialized type of aluminum foil that has undergone a surface treatment to enhance its hydrophilic (water-attracting) properties.

Hydrophilic Aluminum Foil is commonly used in various applications where efficient heat transfer and moisture management are required. The hydrophilic coating applied to the foil’s surface allows it to rapidly and uniformly distribute condensation or liquid, facilitating better heat exchange in heat exchangers, air conditioning systems, and radiators.

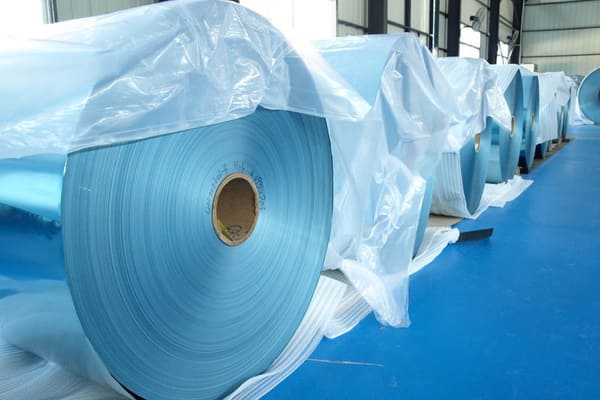

Aluminum Hydrophilic Foil

Compared to regular aluminum foil, which has hydrophobic properties and repels water, Hydrophilic Aluminum Foil offers superior performance in terms of heat transfer efficiency and corrosion resistance.

| Alloy | Temper | Thickness(mm) | Tensile Strength(MPA) | Elogation At 50mm Interval(%) | Cup I.E,mm |

| 1100 3102 8011 |

O | 0.08-0.20 | 80-110 | ≥20 | ≥6.0 |

| H22 | 0.08-0.20 | 100-130 | ≥18 | ≥6.5 | |

| H24 | 0.08-0.20 | 115-145 | ≥16 | ≥6.0 | |

| H26 | 0.08-0.20 | 135-165 | ≥10 | ≥5.5 | |

| H18 | 0.08-0.20 | ≥160 | ≥6 | – |

Note: As the raw material of hydrophilic foil, 8011 aluminum foil is the most common alloy

| INNER DIAMETER | 76/152MM. |

| Thickness And Thickness Tolerance : | |

| Thickness(mm) | Thickness Tolerance |

| 0.080 | ±0.005 |

| > 0.115-0.130 | ±0.008 |

| > 0.130-0.32 | ±0.010 |

| Width And Tolerance : | |

| Width(mm) | Width Tolerance |

| ≤500 | ±0.005 |

| > 0.115-0.130 | ±0.008 |

| > 0.130-0.32 | ±0.010 |

| REEL : | |

| Width(mm) | Width Tolerance |

| ≤1400 | +2.0,0 |

| Telescopic And Layer : | |

| Telescopicy: 5MM | Layer: 0.5mm |

Note: Hydrophilic aluminum foil is available in jumbo rolls, there is a certain relationship between tolerance and size.

| Item | Inspection Methods | Technical Requirements | |

| Film (Double Surface) |

Weighing | Anti-Corrosion:1.6—2.0G/M2

Hydrophilic:0.4-0.7G/M2 |

|

| Adhesion | Cup Test:5mm | No De-Laying | |

| Jis4001 Network Test(100/100) | No Peeling | ||

| T Test(180 Degree) | No De-Laying | ||

| Hydrophilic | Initial Phase | Coating Status | ®≤5C |

| Continuous Test Phase | Dipping 100 Hours In Flow Water (300 L/H),Drying For 2 H, Then Test | Humidity100%:®≤20C | |

| Dry Cycle 300 Times | Humidity 100%:®≤28c | ||

| Dipping Into Volatilizing Solvant For 5min. And Drying It In Temperature 150 Degree, Then Dipping Into Flow Water For 5min. Then Drying In Oven Of Temperature 150 Degree For 150 Degree, Then Test It | Humidity 100%:®≤28C | ||

| Anti-Corrosion | Jisz2371 Nutual Salt Spray Test(72 H) | R.NO.≥9.8 | |

| Anti-Alikalinity | Sample Dip For 3min In 20% Naoh For 20 C+/-1 C | No Changing | |

| Anti-Hot | In 200+/-5c Oven For 10min. View Film Color | No Changing | |

| In 300+/-5 Oven For 5min, View The Color | Slightly Green | ||

| Anti-Oil | Dipping Into Volatilizing

Oil(Af-2c,Af-2as,T7k18b,Rf-190) For 24 H |

No Peeling | |

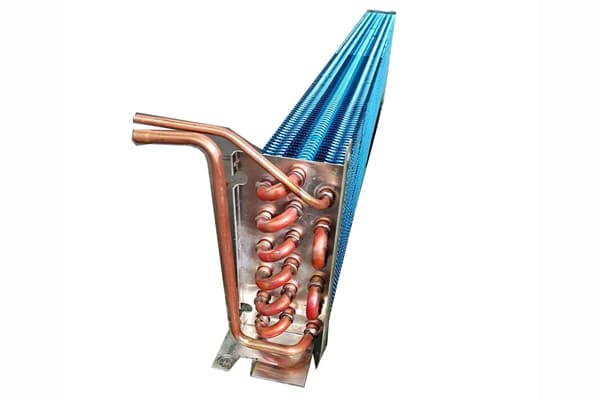

The hydrophilic coating on the aluminum foil promotes improved moisture absorption and increases the surface area, resulting in enhanced heat transfer efficiency. This allows for better cooling and heat dissipation, making it ideal for heat exchangers, air conditioning systems, and refrigeration units.

Hydrophilic Aluminum Foil is highly resistant to corrosion, making it suitable for applications in humid and corrosive environments. This resistance ensures the durability and longevity of the foil, even in challenging conditions, thereby reducing maintenance needs and extending the lifespan of equipment.

By facilitating efficient heat exchange, Hydrophilic Aluminum Foil helps optimize energy usage. It allows systems to cool more effectively, reducing the energy consumption required for maintaining desired temperatures. This can lead to energy savings and cost reduction in long-term operations.

Aluminum is a recyclable material, and the hydrophilic foil can be recycled after use, contributing to sustainable practices and reducing environmental impact. Choosing Hydrophilic Aluminum Foil aligns with eco-friendly initiatives and supports a circular economy.

The production process of hydrophilic aluminum foil is basically the same as that of aluminum foil, except that 3 processes are added in the middle;

Aluminum Hydrophilic Foil Production Line

After the rolling of the aluminum foil is completed, the following 3 steps are performed:

Rewind after the above 3 steps (this process is exactly the same as aluminum foil production)

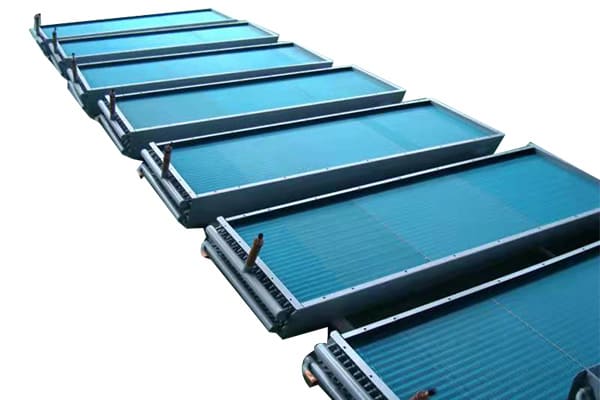

Hydrophilic foil is widely used in refrigeration equipment such as air conditioners and refrigerators, as well as some industrial heat exchange systems;

|

|

|

| Air conditioning systems | Refrigerator | Heat exchangers |

|

|

|

| Radiators | Condenser | Evaporator |

Dry Environment: Store hydrophilic aluminum foil in a dry environment with low humidity levels. Moisture can affect the hydrophilic properties of the foil and lead to degradation.

Temperature Control: Maintain a stable temperature for the storage area. Extreme temperatures can impact the structural integrity and performance of the foil.

Protection from Contaminants: Keep the hydrophilic foil away from dust, dirt, and other contaminants that could potentially affect its surface or hydrophilic coating.

Hydrophilic Aluminum Foil Storage

Avoid Pressure and Impact: Avoid placing heavy objects or applying pressure on the stored hydrophilic foil. Excessive pressure or impact can cause deformation or damage to the foil, compromising its effectiveness.

Ordinary aluminum foil cannot meet the requirements of energy saving, environmental protection, corrosion resistance, and antibacterial for air conditioners. Hydrophilic aluminum foil has strong hydrophilicity. The water droplets condensed on the heat sink are easy to spread and flow down the heat sink to avoid low ventilation effect.

The surface of the hydrophilic aluminum foil is covered with a hydrophilic layer, and the condensed water will spread rapidly on the hydrophilic aluminum foil without condensing into water droplets, which increases the heat transfer area, speeds up the cooling and heating speed, and effectively avoids the noise caused by air flow.

| Hydrophilic Aluminum Foil | Copper Foil | |

|---|---|---|

| Heat Transfer | Good | Excellent |

| Moisture Management | Excellent | Limited |

| Corrosion Resistance | Good | Excellent |

| Weight | Lightweight | Relatively Heavy |

| Cost | Affordable | Expensive |

| Availability | Widely Available | Limited |

| Electrical Conductivity | Moderate | Excellent |

| Compatibility | Suitable for most applications | Suitable for specific applications |

Q:What is hydrophilic coating?

A:acrylic or epoxy

Q:Can Hydrophilic Aluminum Foil be recycled?

A:Yes, Hydrophilic Aluminum Foil can be recycled. Aluminum is highly recyclable and can be processed repeatedly without losing its properties. Recycling Hydrophilic Aluminum Foil helps conserve natural resources and reduces the environmental impact associated with primary aluminum production.

Anodized aluminum sheet is an aluminum sheet placed in the corresponding electrolyte (such as sulfuric acid, chromic acid, oxalic acid, etc.) as an anode, and electrolysis is performed under specific conditions and the action of external current.

3003 aluminum sheet is an alloy with very good corrosion resistance and moderate strength, the reason this metal is widely used is because it is affordable and strong.

1060 aluminium strip cables have excellent load-carrying capacity, especially self-supporting capacity. An aluminum wire can be as long as 4000 meters without falling, while a copper cable can only reach 2750 meters.

6082 aluminum sheet can be heat treated, strengthened and has good formability, weldability and machinability, also known as structural alloy.

Thin aluminum sheet typically refers to a flat piece of aluminum material that has a thickness of less than 6mm (0.24 inches).

Pvdf Coated Aluminum Coil is one type of Color coated aluminum coil, Color coated aluminum coil can be divided into polyester (PE) coated aluminum coil, fluorocarbon (PVDF) coated aluminum coil and epoxy roller coated aluminum coil.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

I need a quotation for 3000 series aluminum sheets/coils (3104 H19) for tuna can production, food-grade finish, delivery to Mazatlán, Mexico.

I am planning a business trip to China and I am very interested in your aluminium 8011 products for food container production. I would like to visit your factory during my stay in china: See your production lines (foil rolling, annealing, slitting, packing). Discuss specifications (8011-O temper, thickness 0.05–0.08 mm, jumbo roll). Review your quality certificates and export experience. Could you please let me know: Your available dates for a visit The location of your factory If you can provide an invitation letter for my business visa (M visa). Thank you for your kind support. Looking forward to your reply. Best regard: LOUNIS MUSTAPHA company name:TOP BARQUETTE SELECT [email protected] what's up:213 770 91 69 43

Merhaba ; Burak ÜNAL ben. Antalya ' da Ambalaj ve Temizlik ürünleri tedarik eden bir firmanın yetkilisiyim. Ayrıca P.E Streç aktarım işi yapmaktayım. Makinalarımızı 9 ve 10 micron alüminyum folyo aktarımına uyacak şekilde revize edeceğiz. Sizden istediğim, 9 veya 10 micron olacak şekilde 35 cm ve 45 cm jumbo folyolar için fiyat, termin ve şu bilgileri istiyorum ; 35 cm jumbo folyonun ortalama ağırlığı. 45 cm jumbo folyonun ortalama ağırlığı. Deneme olacağı için bu 2 ölçüde minimum sipariş tonajımız ne kadar olması gereklidir. İyi çalışmalar.

We are A Commercial Lighting 's parts and accessories Manufacturer in egypt below is our current requirements for production process from aluminum coil (Alloy 1050 temper O thickness 0.3 mm width 25cm=10tons width 29.5cm=6tons width 33.5cm=5tons width 37 cm=5tons kindly send us your best quotation ASAP according to our company below details: Below is our company details : Full legal company name: Focused ligth for industrial investment ., Co address: Plot no 8 - extension of 4th industrial - zone sadat - minofia - egypt Telephone number Ahmed nseem +201016644789 & +201010879400 Eng Moh El shrief : Mob : +2 01016644789 Tax ID number : 699-483-174

I am writing to inquire about the products that your company offers. I am particularly interested in the product listed below: *Aluminum Coil QTY-20 Units Could you please provide me with more information on these products, including pricing, availability, and any additional details that may be relevant? and also quote your ordinary unit price for supplying these product, together with your discount price for the volume purchase of full truck load. Note: Additionally to the above, our standard Payment Terms:Net 15days to 30 days from the date of supply with the supplier's Invoice.