In the process of global economic development, environmental and energy issues have attracted worldwide attention and become important issues restricting the sustainable development of countries.

In the process of global economic development, environmental and energy issues have attracted worldwide attention and become important issues restricting the sustainable development of countries. As far as the automotive industry is concerned, it is necessary to increase the attention paid to energy-saving and environmentally friendly design of automobiles. At present, lightweight development is an important way for various automobile companies to enhance their competitiveness. After the concept of lightweight automobiles was proposed, many lightweight materials were used in automobile production, which is a focus of attention in the development of the automobile industry. Among lightweight materials, aluminum alloy sheets have been widely used in automobile production because of their low density, high strength, high recovery rate and good impact resistance, becoming an ideal material for automobile production. Compared with other lightweight materials, the application cost of aluminum alloy sheets is relatively low and the application range is relatively wide.

Aluminum alloy for automobile skin

In the earth’s crust, the content of aluminum alloy is relatively high. Aluminum alloy sheets can be made into automobile covering materials with high strength, good impact resistance and low density by using certain processing technology. At the same time, this type of material also has the advantage of high recycling rate, which is consistent with the sustainable and environmentally friendly development trend of the automobile industry. Compared with steel alloys, aluminum alloy materials have greater advantages. The performance of aluminum in terms of strength and stiffness is lower than that of iron, but aluminum alloy materials produced by certain processing technology have high strength and hardness. At the same time, since the density of aluminum is lower than that of steel elements, even if the thickness of aluminum alloy sheets increases, its overall mass is still small. Using it in automobile production will have a better lightweight effect. With the continuous improvement of my country’s social development level, the number of automobiles has continued to grow, which has also increased people’s attention to the treatment of scrapped cars, and research on the recycling and reuse of scrapped automobile materials has been continuously strengthened. This is consistent with the country’s green development concept. Aluminum alloy materials are a green automobile manufacturing material with a relatively high recycling value and a high recycling rate. In automobile production, the use of aluminum alloy materials can achieve lightweighting of automobiles while ensuring the safety performance of automobiles, which is conducive to reducing fuel consumption and reducing environmental pollution caused by automobile exhaust. At the same time, lightweighting of automobile parts can ensure the improvement of the rotation efficiency of automobile parts, thereby improving the fuel utilization rate of automobiles. The effective use of aluminum alloy materials can improve the safety of automobile operation. The use of aluminum alloy materials on the car body can improve the braking performance of the car, reduce the traction load borne by the car, and prevent the car from generating a large impact force in the event of a serious collision, thereby causing serious harm to the driver. The use of aluminum alloy materials can reduce the weight of the car and extend the range of new energy vehicles. New energy vehicles that use electricity as the core energy source need to do a good job in lightweighting internal parts, batteries and body. Aluminum alloy materials can effectively meet the needs of new energy vehicle production. Under the condition of ensuring the original stiffness and strength of the parts, it can achieve lightweighting of new energy vehicles and extend their range.

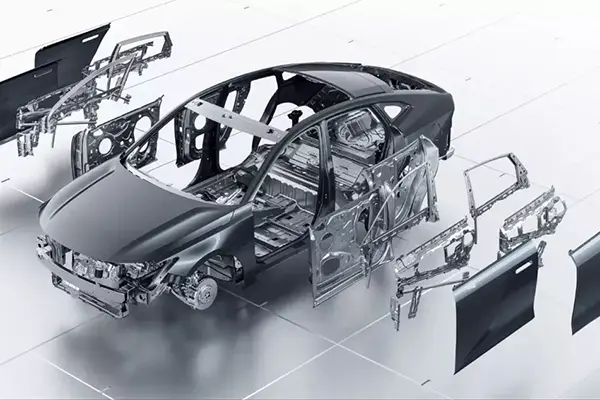

As the largest component in the whole vehicle, the automobile body accounts for about 30% of the total weight of the vehicle and about 70% of the fuel consumption. The key to achieving lightweight automobiles lies in achieving lightweight body. The impact of aluminum alloy body-in-white on automobile lightweighting was analyzed, and the results showed that the lightweight coefficient was inversely proportional to the proportion of aluminum alloy used in the body-in-white. Using aluminum alloy body-in-white is an effective measure to achieve lightweight automobiles.

Automobile chassis is one of the core components of automobiles, accounting for about 27% of the total weight of the vehicle, second only to the body-in-white and powertrain. Its lightweight research is of great significance to promoting automobile lightweighting.

Zhang Guanghe et al. studied its forming process, vehicle example design, etc. based on the current market distribution and aluminum alloy lightweight research. The results show that aluminum alloy has a low density, and the weight of the steering knuckle is reduced after improvement. Extrusion casting will become the main choice for lightweighting vehicle chassis. Huang Yucai studied how to achieve lightweight chassis for light trucks and concluded that using lightweight materials is one of the main ways to achieve lightweight, among which lightweight aluminum alloy is the best. Lu Daxing et al. discussed the lightweight status of aluminum alloy chassis and the new extrusion casting process based on the lightweight process, products and trends of aluminum alloy automobile chassis, and believed that extrusion casting will promote the wider application of aluminum alloy materials.

As the power source of automobiles, automobile engines are the key part of automobile movement. They determine the overall performance of automobiles and have an important impact on the service life and driving experience of automobiles. Aluminum cylinder blocks, cylinder heads and intake manifolds can reduce the weight of engines by 30% to 40%, and at the same time can increase the engine compression ratio, reduce thermal stress, and increase engine power. Wang Lixin et al. studied the scheme for achieving lightweight engines, stating that the ultimate result of achieving lightweight engines is to achieve lightweight engine specific parts, and proposed that the use of low-strength fasteners and aluminum instead of steel can achieve the reduction of their mass and cost. In order to achieve lightweight automobiles, Chen Yun et al. proposed the use of extrusion casting to produce aluminum alloy engine suspension brackets, designed the entire casting process, and conducted production verification. The results show that this measure can meet the use requirements.

Aluminum alloy for automobile engine

Automobile wheels use aluminum alloy plates to achieve lightweight, which can reduce automobile energy consumption and environmental pollution when the car is driving. Aluminum alloy automobile wheels have poor thermal conductivity, and will not cause tire blowouts due to heat generation and heat conduction during automobile braking, which can improve the safety of automobile driving. The use of aluminum alloy automobile wheels and radial tires can minimize the impact of automobile vibration and buffering, thereby ensuring the comfort of the car. Aluminum alloy automobile wheels have strong fluidity and tension, so after polishing, the appearance is beautiful, especially after anti-corrosion treatment, the appearance is kept for a long time. Compared with automobile wheels made of other materials, aluminum alloy automobile wheels have obvious advantages, which are mainly reflected in two aspects. First, they are energy-saving and simple. This is mainly determined by the characteristics of aluminum alloy plates. They have a small density, which can reduce energy consumption while reducing the weight of the car body, ensure the improvement of acceleration performance, have a positive effect on automobile braking, and reduce pollution to the environment. Second, they have excellent performance. Aluminum alloy automobile wheels have good vibration reduction and heat dissipation performance, which can minimize the occurrence of tire blowouts caused by excessive temperature, thereby improving the safety of automobile driving.

When improving the quality of automobile wheel casting, it is necessary to do a good job of quality control, analyze the quality problems that may occur in casting, and formulate perfect solutions. As far as low-pressure casting technology is concerned, it is necessary to control the mold making process, inject dry compressed air into the mold, and maintain pressure to ensure that all work is completed with high quality and efficiency. During pipeline cooling, the mold will be affected by the opening sequence and opening time. In addition, for mold making, it is also very important to control the temperature. It is necessary to ensure that the temperature of the mold is stable, the structure of the wheel is compact, and the internal organization is tight. Generally speaking, cooling media such as water and water mist need to be injected into the cooling channel. In actual operation, attention should also be paid to controlling the temperature and flow of the cooling medium.

Aluminum Alloy Wheels

When verifying the cooling effect, it is necessary to set thermocouples at different mold positions to monitor the temperature change. If the spinning casting process is selected, the rotational motion and extrusion effect must be controlled. In this process, common methods include slab split spinning, tube rim spinning and precast blank strong spinning. During casting, the precast blank should be preheated to ensure the improvement of spinning efficiency and thus improve product quality. Before spinning, it is necessary to ensure that the surface of the blank is clean, smooth and free of flash. Predictive processing can be used to ensure the cleanliness of the mold surface. During the spinning work, the rim shape should be confirmed and the processing size should be controlled. In addition, special attention should be paid to ensure the quality of the rim to prevent relatively large defects from affecting product quality.

In foreign countries, automobile companies in many countries use aluminum alloys and will cooperate with professional aluminum alloy manufacturers to participate in the R&D and production of aluminum alloys to ensure the professionalism of aluminum alloy production and the quality of aluminum alloy sheets. Therefore, when manufacturing automobiles, in order to improve the lightweight effect of automobiles, it is necessary to cooperate with professional automobile aluminum alloy manufacturers to ensure that the quality of aluminum alloy sheets meets the requirements. A professional automobile aluminum alloy R&D organization can be established to improve the performance of aluminum alloy sheets to reduce the weight of the car body.

Due to the high price of aluminum alloy sheets, it is not currently widely used in automobile manufacturing. The mechanical properties of aluminum alloys are significantly superior to other materials. Although aluminum is a relatively abundant element in the earth’s crust and its output is only lower than that of iron, the energy consumption of aluminum refining is higher than that of iron, and the equipment cost required is also high, so its price is much higher than that of iron. The price of aluminum alloy is about 3 times that of steel. In order to expand the application scope of aluminum alloy sheets, it is necessary to improve their cost performance, increase R&D investment, optimize performance, and do a good job of cost control, so as to enhance the market competitiveness of aluminum alloy sheets, effectively give play to the advantages of aluminum alloy sheets, and realize lightweight production of automobiles.

8021 aluminium foil is a common alloy in 8000 series aluminum alloys. Common aluminum foils in 8000 series aluminum alloys include 8011 Aluminum Foil and 8079.

Aluminum foil for hookah is commonly used for preparing and using a hookah, also known as a shisha or water pipe. It serves a specific purpose in the preparation of the hookah, particularly in the placement and management of the charcoal and tobacco.

Pvdf Coated Aluminum Coil is one type of Color coated aluminum coil, Color coated aluminum coil can be divided into polyester (PE) coated aluminum coil, fluorocarbon (PVDF) coated aluminum coil and epoxy roller coated aluminum coil.

1050 aluminum sheet is a kind of non-heat-treated aluminum plate, which has good plasticity, corrosion resistance, electrical conductivity and thermal conductivity after cold working;

6061 aluminum sheet is an al-si-mg alloy that has been strengthened by precipitation hardening. 6061 aluminum has a high strength-to-weight ratio, above-average corrosion resistance, good machinability, and is well suited for welding.

The 1000 series aluminum sheet is a series of pure aluminum sheets. Its composition is mainly aluminum, with a content of more than 99%.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

Dear Sir, Please offer your best FOB Prices specs are as under ALUMINIUM STRIP (AL=99.50% MIN) SIZE:450 X32 X6 MM. DIN EN 570 EN-AW 1050 A, QUANTITY=3400KG

Hello, Would you be so kind to offer item as follows: Coil 0,6х1250 (1000)mm EN AW-3105 5tons

Hello, Can you offer me Aluminium plates? Actally I need: 110mm x 1700mm x 1700mm 5083 H111 - 21 pcs Next year planed is 177 pcs

Świetny artykuł. Byłem zachwycony, że wyszukałem ten artykuł. Wielu osobom wydaje się, że mają rzetelną wiedzę na ten temat, ale często tak nie jest. Stąd też moje miłe zaskoczenie. Jestem pod wrażeniem. Zdecydowanie będę rekomendował to miejsce i częściej wpadał, aby zobaczyć nowe rzeczy.

requirement of aluminium strip