Many customers think that 1060 aluminum plate and 6061 aluminum plate products are similar and look similar on the surface, but in fact, the difference between the two is quite large.

Many customers think that 1060 aluminum plate and 6061 aluminum plate products are similar and look similar on the surface, but in fact, the difference between the two is quite large. Therefore, today we will focus on analyzing and comparing the difference between 1060 aluminum plate and 6061 aluminum plate.

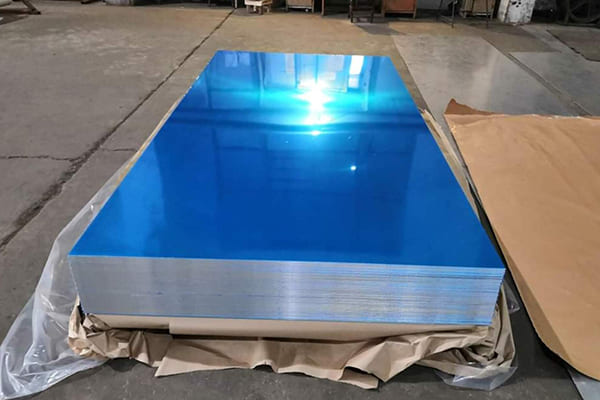

The difference between 1060 aluminum plate and 6061 aluminum plate

1060 aluminum plate is a commonly used material in the 1000 series alloy aluminum plate, with an aluminum content of about 99.60%. It is generally pure aluminum, soft and suitable for stamping, stretching and other advantages. It currently occupies a relatively large advantage group in the downstream customer processing field. It belongs to the commonly used aluminum plate series, and the 1060 aluminum plate has a low price, good cost control, mature technology, and basically all can be done. Therefore, in the field of aluminum plate use, 1060 aluminum plate occupies a considerable main force.

6061 aluminum plate is a commonly used aluminum plate in the 6 series. We all know that the 6000 series aluminum alloy is mainly aluminum-magnesium alloy. Its advantage is that while maintaining hardness, it has good welding performance and is corrosion-resistant and anti-oxidation. Therefore, 6061 aluminum plate is widely used in the field of ships. In addition, 6061 aluminum plate is a hot-rolled aluminum plate process compared with 1060 aluminum plate process, which is relatively more complicated.

Chemical composition

1060 aluminum plate is an almost pure aluminum product, with an aluminum content of usually more than 99.6%, and basically no other technical elements.

6061 aluminum plate is an aluminum alloy, the main alloying elements include magnesium and silicon, and sometimes also contains a small amount of copper, iron, manganese and other elements.

Production process

The production process of 1060 aluminum plate is relatively simple, and the technology is mature and stable.

The production process of 6061 aluminum plate is relatively complex, and usually requires heat treatment to improve its mechanical properties.

Physical properties

Hardness and strength: Since 6061 aluminum plate contains alloying elements, its hardness and strength are usually higher than 1060 aluminum plate.

Corrosion resistance: 6061 aluminum plate has good corrosion resistance after proper heat treatment and surface treatment.

Weldability: 6061 aluminum plate has good welding performance.

Conductivity and thermal conductivity: 1060 aluminum plate has high conductivity and thermal conductivity because it is close to pure aluminum.

Applications

1060 aluminum sheet is usually used in applications where strength requirements are not high, such as signs, billboards, building exterior decoration, kitchen utensils, lighting components, etc.

6061 aluminum sheet is suitable for various industrial structural parts that require certain strength, weldability and corrosion resistance, such as aircraft parts, trucks, bridges, ships, etc. due to its good comprehensive performance.

6061 aluminum plate for shipbuilding

Price

1060 aluminum sheet has a relatively low price due to its simple production process.

6061 aluminum sheet has a relatively high price due to its complex production process and higher performance requirements.

Surface treatment

1060 aluminum sheet is suitable for a variety of surface treatment methods such as anodizing, spraying, etc. due to its high purity, and can provide good decorative effects.

In summary, the choice of which type of aluminum sheet depends on the specific application requirements. If a material with high strength and good weldability is required, 6061 aluminum sheet should be selected; if a material with low cost and low strength requirements is required, 1060 aluminum sheet is a suitable choice.

3003 aluminum sheet is an alloy with very good corrosion resistance and moderate strength, the reason this metal is widely used is because it is affordable and strong.

1070 aluminum alloy belongs to the 1000 series pure aluminum with an aluminum content of 99.7%. It is widely used in electronics, electricity, construction, aerospace and other fields.

8021 aluminium foil is a common alloy in 8000 series aluminum alloys. Common aluminum foils in 8000 series aluminum alloys include 8011 Aluminum Foil and 8079.

1050 aluminum strips belongs to the family of commercially pure malleable 1000 series alloys, and the aluminum is 99 pure. 5%, with excellent molding processing characteristics, high corrosion resistance, good electrical and thermal conductivity.

Aluminum circle for road sign refers to the aluminum circle used in the production of road signs. Because aluminum circles have strong corrosion resistance and weather resistance, aluminum circles are very suitable for the production of road signs.

Heavy duty aluminum foil provides extra strength and tear resistance. Many cooks use it for baking, grilling, and storage. Most foil rolls marked "heavy duty" are between 0.0008" and 0.001" thick, which is roughly 0.02032-0.0254mm in national units

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

Dear Sir, Please offer your best FOB Prices specs are as under ALUMINIUM STRIP (AL=99.50% MIN) SIZE:450 X32 X6 MM. DIN EN 570 EN-AW 1050 A, QUANTITY=3400KG

Hello, Would you be so kind to offer item as follows: Coil 0,6х1250 (1000)mm EN AW-3105 5tons

Hello, Can you offer me Aluminium plates? Actally I need: 110mm x 1700mm x 1700mm 5083 H111 - 21 pcs Next year planed is 177 pcs

Świetny artykuł. Byłem zachwycony, że wyszukałem ten artykuł. Wielu osobom wydaje się, że mają rzetelną wiedzę na ten temat, ale często tak nie jest. Stąd też moje miłe zaskoczenie. Jestem pod wrażeniem. Zdecydowanie będę rekomendował to miejsce i częściej wpadał, aby zobaczyć nowe rzeczy.

requirement of aluminium strip