Aluminum is a legendary metal. Thanks to the advancement of production technology, aluminum has transformed from a noble metal to a popular material and has gradually entered every aspect of social life. Among them, the miracle created by thin aluminum foil is a new perspective worth sharing.

Aluminum element

Metal foil is actually a very thin sheet material, which often has different properties and applications due to different metal types. Generally speaking, the better the ductility of the metal, the thinner the metal foil processed with it will be.

In fact, the processing and application of metal foil has a very long history. However, the ancients used a very primitive hammer forging method to process metal foil, that is, stacking hundreds of metal sheets and then pressing them into foil by manual hammer forging. Metal foils such as gold foil, silver foil, lead foil, and tin foil in ancient times were made using this method.

Aluminum foil has been in our lives for more than 100 years, but in many cases, aluminum foil still lives in the shadow of tin foil. Because from the appearance, aluminum foil and tin foil are almost difficult to distinguish. Since tin foil has a longer history than aluminum foil, even though aluminum foil dominates the world now, people are still used to calling aluminum foil “tin foil”.

Flexible Packaging Aluminum Foil Food Packaging

It is reported that the history of tin foil can be traced back to the late 18th century. In addition to food packaging, its application can also be used in medicine, chemicals, light industry, electronics and art supplies. Around 1910, the world’s first aluminum foil rolling plant was born in Switzerland, and the history of aluminum foil replacing tin foil began.

The reason why aluminum foil can replace tin foil depends entirely on the many advantages of aluminum foil. First, the cost of aluminum foil is much lower than that of tin foil, and it has high durability, so it is more easily accepted by consumers. Secondly, the melting point of aluminum foil is much higher than that of tin foil, and its thermal conductivity is also better, so it is more popular when cooking and baking food. Additionally, storing food in tin foil often develops an unpleasant bitter taste, while aluminum foil does not have this problem.

1911 is an important time node in the history of food packaging in the world. Because this year is the first year of aluminum foil in the field of food packaging, and thus it has opened its glorious journey in the field of food packaging. As a pioneer of aluminum foil packaging, a Swiss chocolate company has grown for more than 100 years and has now become a well-known brand (Toblerone).

Aluminum foil usually refers to aluminum with a purity of more than 99.5% and a thickness of less than 0.2 mm, while the thickness of aluminum foil used for composite materials will be thinner. Of course, different countries have different requirements for the thickness and composition of aluminum foil. The question is, can aluminum foil as thin as a cicada’s wing be competent for the task of food packaging? This has to start with the mission of food packaging and the characteristics of aluminum foil.

Although food packaging is generally inedible, it is an important part of the attributes of food commodities. In terms of the function of food packaging, the most core function is food protection. Food goes through a complex process from production to consumption, so it may be affected by external factors such as biological, chemical, and physical factors in the environment. Food packaging should be able to maintain the stability of food quality and resist various adverse effects in the environment. At the same time, food packaging should also meet the requirements of beauty, convenience, environmental protection, and low price.

However, in food packaging practice, aluminum foil is rarely used alone because it has some shortcomings. For example, as the aluminum foil is further thinned, the number of pores will increase, which will affect the barrier properties of the aluminum foil. At the same time, thin and soft aluminum foil has limitations in tensile and shear resistance, and is usually not used for structural packaging. Fortunately, aluminum foil has good secondary processing performance. It can usually be composited with other packaging materials to make up for the shortcomings of aluminum foil, thereby improving the comprehensive packaging performance of composite packaging materials.

We usually call a film composed of two or more materials a composite film, and a packaging bag made of a composite film a composite film bag. In general, plastics, aluminum foil, paper and other materials can be made into composite films by bonding or heat sealing to meet the different packaging needs of a variety of foods. In modern packaging, almost all composite materials that require opacity and high barrier properties use aluminum foil as a barrier layer. This is because aluminum foil has a highly dense metal crystal structure and has good barrier properties for any gas.

Application of aluminum foil

In food soft packaging, there is a packaging material called “vacuum aluminized film”. Is it the same as aluminum foil composite packaging material? Although both contain a very thin aluminum layer, they are not the same material. Vacuum aluminized film is made by evaporating high-purity aluminum onto plastic film under vacuum, while aluminum foil composite materials are made by bonding or heat-sealing aluminum foil and other materials together.

Unlike aluminum foil composite materials, the aluminum layer in aluminized film does not have the barrier effect of aluminum foil. The barrier effect is the base film itself. Since the aluminum layer is much thinner than aluminum foil, the cost of aluminized film is lower than that of aluminum foil composite materials, and its application market is also very wide, but it is generally not used for vacuum packaging.

In addition to food packaging, pharmaceutical packaging is also a major issue that cannot be ignored. As a special commodity, the entire chain from the factory to the use of medicines cannot be separated from the protection of pharmaceutical packaging. Therefore, whether the pharmaceutical packaging is scientific and reasonable is directly related to the safety and efficacy of the medicine.

Aluminum foil jumbo roll

Pharmaceutical packaging has a long history, but it has always been closely related to the level of progress in materials science. In 1952, the application of aluminum foil blisters in the pharmaceutical field opened up a new concept of pharmaceutical packaging. So, what is blister packaging? As a major form of pharmaceutical packaging, blister packaging is generally composed of covering materials and blister materials. The covering material is usually aluminum foil or composite aluminum foil, which mainly plays a sealing role and serves as an inner label for medicines; while the blister material is usually a hard sheet composed of polyurethane, polyethylene, polypropylene hard sheets and related materials, which is the structural material of the blister cavity.

Why choose aluminum foil as a pharmaceutical packaging material? This is determined by the physical and chemical properties of aluminum foil. Aluminum foil has light-shielding, moisture-proof and anti-pollution functions, and has certain advantages in the field of pharmaceutical packaging. Regarding the barrier properties of blister packaging, according to the different materials and the thickness of the blister, it can be divided into two types: moisture barrier and oxygen barrier.

Blister packaging of medicines is also called “blister packaging”, referred to as PTP (Press Through Packaging). Because blister packaging has good mechanical properties, high and low temperature resistance and corrosion resistance, it is suitable for modern automated packaging production line operations. Generally, blister packaging is suitable for automated packaging of medicines in dosage forms such as tablets, capsules, pills, suppositories, powders, etc.

For aluminum foil blister packaging, the production process is: first, the transparent plastic hard sheet is blister-formed, and then the medicines in different dosage forms such as tablets, pills, granules or capsules are filled in the groove, and then heated and bonded with the aluminum foil coated with adhesive. In this way, an independent sealed package is formed.

Aluminum foil blister packaging is usually a single-dose package, that is, it can hold a single dose of medicine for a single patient. In order to improve the consumer experience, blister packaging is easy to use hard aluminum foil as the covering material, which makes it convenient for consumers to take out the medicine immediately after tearing off the aluminum foil.

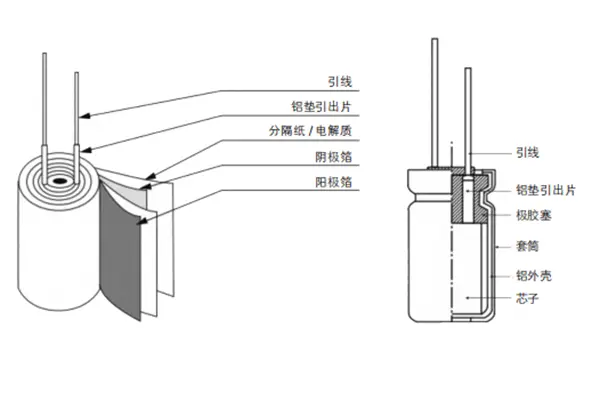

In the electronics industry, aluminum foil is mainly used in capacitor production. As one of the most basic electronic components, electrolytic capacitors are widely used in communications, electronics, home appliances, automobiles, aviation and other fields. So why is aluminum foil used in the production of capacitors?

We usually call aluminum foil used in electrolytic capacitors electronic aluminum foil, and electrolytic capacitors using aluminum foil are called aluminum electrolytic capacitors. Aluminum electrolytic capacitors have a pivotal position in the composition of capacitor products because of their advantages such as large capacitance, low cost and small size.

Electronic aluminum foil is the key raw material for the production of aluminum electrolytic capacitors and accounts for a considerable proportion of its cost structure. Electronic aluminum foil is actually just the blank of the electrode foil used in aluminum electrolytic capacitors, which can be further converted into electrode foil. Electrode foil is the core material of aluminum electrolytic capacitors and directly affects the performance of aluminum electrolytic capacitors. Electrode foil can be divided into cathode foil and anode foil, and its function is to store charge.

Electronic aluminum foil

So, how is electronic aluminum foil converted into electrode foil? Depending on the production stage, electrode foil can be divided into corrosion foil and chemical foil. The former is a porous aluminum foil (cathode foil) formed by corrosion of electronic aluminum foil, while the latter is an aluminum foil (anode foil) with an oxide film on the surface formed by chemical formation on the basis of corrosion foil.

Aluminum foil also plays an important role in power lithium batteries, so it is an emerging material in the development history of new energy vehicles. At present, battery foil is mainly divided into two categories: battery aluminum foil and battery copper foil. The former is mainly used as the positive electrode current collector of lithium-ion batteries, while the latter is mainly used as the negative electrode current collector of lithium-ion batteries.

As one of the indispensable and important components in lithium-ion batteries, the current collector has multiple functions of carrying electrode active materials (such as lithium iron phosphate, etc.) and collecting output current. The selection of suitable positive and negative current collector materials is of great significance to improving the charging and discharging efficiency of lithium batteries. The development of new energy vehicles is inseparable from high-performance power batteries. Introducing battery aluminum foil into the current collector not only meets the requirements of lightweight vehicles, but also is crucial to improving the performance of power batteries.

Carbon-coated aluminum foil, which is widely used in lithium iron phosphate power batteries, is made by coating dispersed conductive carbon black or carbon coating particles on an aluminum foil substrate. Carbon-coated aluminum foil can improve the energy density of the battery, inhibit the polarization of the battery, reduce the internal resistance of the battery, and increase the cycle life of the battery. Applying carbon-coated aluminum foil to the positive current collector can improve the contact interface between the positive active material and the aluminum foil, thereby achieving the purpose of improving battery performance.

With the advancement of electrical science and technology, aluminum foil also has a place in the transformer manufacturing industry. Aluminum foil, as the most commonly used material for some transformers, is closely related to its excellent performance. For example, aluminum foil has high electrical and thermal conductivity. Using it as a winding material for a transformer can not only reduce the loss of the transformer, but also improve the performance of the transformer. Aluminum foil is also used in air conditioners, which are a great tool for cooling down the heat. Air conditioning aluminum foil, as a special material for manufacturing air conditioning heat exchanger fins, has been used for decades. Here, the characteristic of aluminum foil that it is easy to transfer heat (cold) is utilized.

However, most of the air conditioning aluminum foil used in the early days was plain foil. The so-called plain foil refers to aluminum foil without coating on the surface. With the advancement of household air conditioners, various modified aluminum foils have emerged. Among them, hydrophilic aluminum foil is a typical case. The so-called hydrophilic aluminum foil refers to a modified aluminum foil made by applying a hydrophilic coating and an anti-corrosion coating on a plain foil.

Because the hydrophilic aluminum foil has strong hydrophilicity, it is conducive to the spreading and discharge of water on the heat exchange plate, and improves the heat exchange efficiency by 10% to 15%. At the same time, the hydrophilic aluminum foil also has the advantages of anti-corrosion, antibacterial, energy saving, noise reduction, odorlessness and extended service life. Today, new varieties such as highly corrosion-resistant hydrophilic aluminum foil, antibacterial hydrophilic aluminum foil, super hydrophilic aluminum foil, and nano-organic hydrophilic aluminum foil have been industrialized.

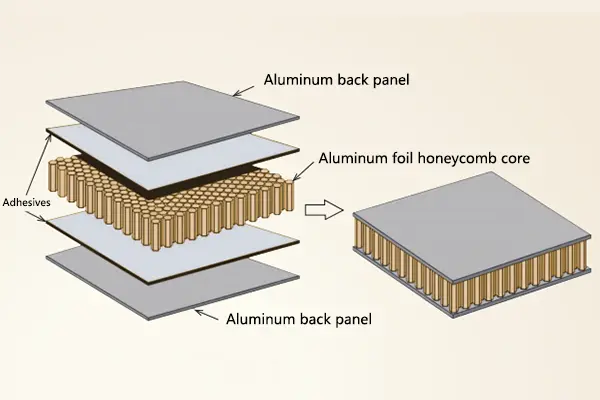

The amazing honeycomb has always been the research object of bionic science. Scientists have long discovered that the unique structural characteristics of honeycombs enable them to achieve more functions with less material and have very good overall stability. Therefore, we can get inspiration from it and create new environmentally friendly materials to meet the special needs of certain fields.

Honeycomb structural materials(honeycomb aluminum foil), as a new type of environmentally friendly composite materials, were first used in the aviation field. In the 1940s and 1950s, honeycomb structural materials were first used in military aircraft, and then in civil aircraft. Today, honeycomb structural materials have been widely used and have played an important role in aerospace, construction, ships, high-speed rail and other fields.

Aluminum honeycomb

Honeycomb structural materials are also called honeycomb sandwich panels, which are generally aluminum sandwich structures. Its structure is extremely simple, that is, an aluminum back plate is attached to the upper and lower parts of the aluminum foil honeycomb core. So, what are the advantages of honeycomb structure? When subjected to a load perpendicular to the back plate, the aluminum foil honeycomb core is almost the same as the solid structure, or even slightly better. Why not create the strongest geometric structure with the least amount of material?

Of course, behind the “lightness” and “strength” of aluminum honeycomb structural materials, there is also a little-known “soul”. This “soul” is heat insulation and sound insulation. Since aluminum materials are good conductors and media for heat and sound, where do heat insulation and sound insulation come from?

It turns out that the core of aluminum honeycomb structural materials is an aluminum foil honeycomb structure, in which hexagonal holes occupy most of the space. If the thickness of the aluminum foil used to make the honeycomb core is 0.1 mm, then the solid part only accounts for a few percent of the total volume. Because the upper and lower backboards seal the hexagonal columnar space of the honeycomb core very tightly, the air in the aluminum honeycomb structure cannot circulate. When the air is trapped, heat is difficult to transfer, and the propagation of natural sound waves will also be greatly restricted. In this way, aluminum honeycomb structural materials undoubtedly have good heat insulation and sound insulation properties.

So, in what occasions can aluminum honeycomb structural materials be used? In the aviation field, aluminum honeycomb structural materials can be used in wings, vertical tails, cockpits, cargo hold floors, door partitions and other occasions. In the field of new energy, the material can be used as a heat-absorbing material for solar panels and wind turbines. In the field of railway transportation, the material can be used in train bulkheads and floors. In the field of construction, the material is used as curtain walls, blinds and ceilings of high-rise buildings, as well as screen partitions and sound insulation boards in banks, and can also be used to produce portable mobile homes. In the field of packaging, the material can be used in the packaging of food, beverages, cosmetics and electronic products.

In addition to the above-mentioned aluminum honeycomb structural materials, reflective thermal insulation materials based on aluminum foil are also widely used in the construction industry. It turns out that aluminum foil is silvery white, shiny, and has a reflectivity of more than 90% to sunlight, while its own thermal radiation capacity is very low. Therefore, using it as the outer protective material of the insulation structure has a good insulation effect.

The insulation structure mentioned here refers to a complete insulation system including highly reflective materials. Aluminum foil thermal insulation paperboard is a relatively simple insulation system, which mainly uses corrugated paperboard as the base layer, and aluminum foil is attached to it as the surface layer to play a reflective role.

In construction engineering practice, metal reflective insulation structures are diverse. For example, the insulation structure of multi-layer thin-layer air gaps formed by overlapping multiple layers of aluminum foil uses the reflective properties of aluminum foil to make its radiant heat be reflected multiple times in the gaps. In this way, the heat formed in the gaps hinders the convection of heat.

3105 Aluminum Sheet is adding some other elements on the basis of pure aluminum, such as cu, mg, si, mn, etc., the purpose is to improve the strength of aluminum alloy

3003 curtain wall aluminum sheet is the outer wall of a building. It is a lightweight wall of large high-rise buildings and has a certain decorative effect.

Food packaging, household foil raw material 3004 aluminum foil, professional aluminum alloy production expert, 20 production lines

6061-T6 Aluminum floor plate, commonly known as “diamond plate” or “tread plate”, is an excellent candidate for most processing techniques and both interior and exterior applications.

5×10 aluminum sheet is a common specification of aluminum sheet produced by aluminum sheet manufacturers,it is 5 feet wide and 10 feet long.

Pvdf Coated Aluminum Coil is one type of Color coated aluminum coil, Color coated aluminum coil can be divided into polyester (PE) coated aluminum coil, fluorocarbon (PVDF) coated aluminum coil and epoxy roller coated aluminum coil.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

Dear Sir, Please offer your best FOB Prices specs are as under ALUMINIUM STRIP (AL=99.50% MIN) SIZE:450 X32 X6 MM. DIN EN 570 EN-AW 1050 A, QUANTITY=3400KG

Hello, Would you be so kind to offer item as follows: Coil 0,6х1250 (1000)mm EN AW-3105 5tons

Hello, Can you offer me Aluminium plates? Actally I need: 110mm x 1700mm x 1700mm 5083 H111 - 21 pcs Next year planed is 177 pcs

Świetny artykuł. Byłem zachwycony, że wyszukałem ten artykuł. Wielu osobom wydaje się, że mają rzetelną wiedzę na ten temat, ale często tak nie jest. Stąd też moje miłe zaskoczenie. Jestem pod wrażeniem. Zdecydowanie będę rekomendował to miejsce i częściej wpadał, aby zobaczyć nowe rzeczy.

requirement of aluminium strip