The term “melting point” refers to the temperature at which a solid material transitions into a liquid. More specifically, it is the temperature at which the solid and liquid phases of a substance coexist in thermal equilibrium. At this temperature, the substance has an equal probability of being in either its solid or liquid state.

What is the melting point of aluminum

The melting point of a metal is the temperature at which it changes from a solid to a liquid state. The melting points of metals can vary widely depending on the type of metal. Here are some common examples:

From the above data, we can see that aluminum melting point is not high, only 660.32°C, which means that when we melt the aluminum ingot into molten aluminum, we only need to raise the temperature to 660.32°C.

Aluminum melting temperature is 660.32°C, which is relatively low among common metals. The melting points of Fe and Cu are both above 1000°C.

Tungsten is the metal with the highest melting point, up to 3400°C.

Mercury is the metal with the lowest melting point and is liquid at room temperature and pressure,it is melting point is -39°C.

Mercury at room temperature

The aluminum melting temperature is about 660.32°C (1,220.58°F) at standard atmospheric pressure. However, the melting point of aluminum can be affected by a variety of factors, including but not limited to the following:

| Alloy | Melting Range (°F) | Melting Range (°C) | Applications |

| 2024 | 935 – 1180 | 500 – 635 | High strength structural applications, aircraft fuselage and wings, gears and shafts, cylinders and pistons |

| 3003 | 1190 – 1210 | 640 – 655 | Fuel tanks and piping, chemical equipment, heat exchangers, truck and trailer parts, cabinets |

| 5052 | 1125 – 1200 | 605 – 650 | Pressure vessels, marine equipment, fencing, hydraulic tubes, appliances |

| 6061 | 1080 – 1205 | 580 – 650 | Building products, automotive parts, piping, furniture, bicycle frames, railroad cars |

| 7075 | 890 – 1175 | 475 – 635 | Aircraft wings and fuselages, missile parts, gears and shafts, worm gears |

Reproduction and processing

When casting aluminum alloy, solid aluminum alloy needs to be melted into liquid. In this process, we control the ambient temperature and save energy by understanding the melting point of aluminum alloy.

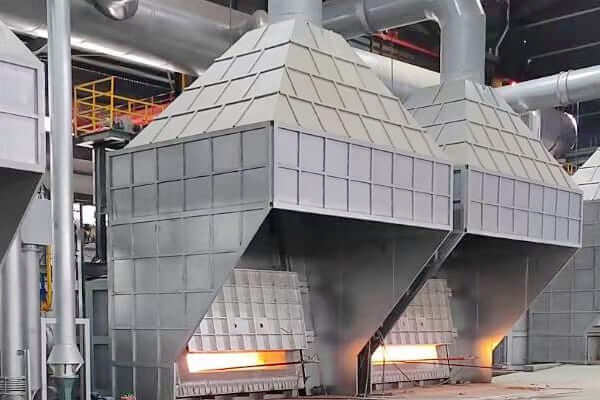

Ingot melting furnace

During the hot working process, too high or too low temperature will affect the processing performance of aluminum alloy. During the heat treatment process, the melting point determines the annealing temperature and quenching temperature, which directly affects the hardness and toughness of aluminum alloy.

In the application and selection of aluminum alloy

When using aluminum alloy, we must understand the melting point of aluminum alloy and the performance changes of different aluminum alloys under high temperature, so as to achieve the best effect.

Applications of aluminum alloy

| Metals | Fahrenheit (f): | Celsius (c): | Kelvin (k): |

| Mercury | -38 | -39 | 234 |

| Phosphorus | 111 | 44 | 317 |

| Selenium | 423 | 217 | 490 |

| Tin | 449 | 232 | 505 |

| Babbitt | 480 | 249 | 522 |

| Bismuth | 521 | 272 | 545 |

| Cadmium | 610 | 321 | 594 |

| Lead | 621 | 328 | 600 |

| Magnesium Alloys | 660-1200 | 349-649 | 622-922 |

| Zinc | 787 | 420 | 693 |

| Aluminum Alloys | 865-1240 | 463-671 | 736-944 |

| Aluminum Bronze | 1190-1215 | 600-655 | 916-930 |

| Magnesium | 1200 | 650 | 922 |

| Pure Aluminum | 1220 | 660 | 933 |

| Beryllium Copper | 1587-1750 | 865-955 | 1137-1228 |

| Manganese Bronze | 1590-1630 | 865-890 | 1139-1161 |

| Sterling Silver | 1640 | 893 | 1166 |

| Admiralty Brass | 1650-1720 | 900-940 | 1172-1211 |

| Yellow Brass | 1660-1710 | 905-932 | 1178-1205 |

| Bronze | 1675 | 913 | 1186 |

| Pure Silver | 1761 | 961 | 1234 |

| Red Brass | 1810-1880 | 990-1025 | 1261-1300 |

| Gold | 1945 | 1063 | 1336 |

| Copper | 1983 | 1084 | 1357 |

| Cast Iron | 2060-2200 | 1127-1204 | 1400-1478 |

| Ductile Iron | 2100 | 1149 | 1422 |

| Manganese | 2271 | 1244 | 1517 |

| Beryllium | 2345 | 1285 | 1558 |

| Monel | 2370-2460 | 1300-1350 | 1572-1622 |

| Hastelloy | 2410-2460 | 1320-1350 | 1594-1622 |

| Carbon Steel | 2500-2800 | 1371-1540 | 1644-1811 |

| Inconel | 2540-2600 | 1390-1425 | 1666-1700 |

| Incoloy | 2540-2600 | 1390-1425 | 1666-1700 |

| Silicon | 2572 | 1411 | 1684 |

| Nickel | 2647 | 1453 | 1726 |

| Wrought Iron | 2700-2900 | 1482-1593 | 1755-1866 |

| Cobalt | 2723 | 1495 | 1768 |

| Stainless Steel | 2750 | 1510 | 1783 |

| Palladium | 2831 | 1555 | 1828 |

| Titanium | 3040 | 1670 | 1944 |

| Thorium | 3180 | 1750 | 2022 |

| Platinum | 3220 | 1770 | 2044 |

| Chromium | 3380 | 1860 | 2133 |

| Rhodium | 3569 | 1965 | 2238 |

| Niobium (Columbium) | 4473 | 2470 | 2740 |

| Molybdenum | 4750 | 2620 | 2894 |

| Tantalum | 5400 | 2980 | 3255 |

| Rhenium | 5767 | 3186 | 3459 |

| Tungsten | 6150 | 3400 | 3672 |

| Tips:

Celsius to Fahrenheit: (°C × 9/5) + 32 Fahrenheit to Celsius: (°F − 32) × 5/9 Celsius to Kelvin: °C + 273.15 Fahrenheit to Kelvin: (°F − 32) × 5/9 + 273.15 |

|||

The above are the melting points of all metals that Henan Huawei Aluminum can know. I hope it can help you. If you have any questions, please contact us:

Whatsapp:+8618137782032

Email: [email protected]

Huawei Aluminum is your reliable partner for 1070 Aluminum Coil products. With our commitment to quality, customization, and competitive pricing, we aim to meet and exceed your expectations.

Our commitment to quality, variety, and customization ensures that you'll find the perfect insulation aluminum coil for your project.

Compared with other alloy foils of series 1, such as 1060 and 1070 aluminum foils, the content of (Fe+Si) in 1100 aluminum foil is higher than both, and the content of Fe is the key factor to improve the strength and toughness

5×10 aluminum sheet is a common specification of aluminum sheet produced by aluminum sheet manufacturers,it is 5 feet wide and 10 feet long.

Brushed aluminum plate is a flat piece of aluminum material that has been treated with a brushing process to produce a uniform, unidirectional texture on its surface.

1050 Aluminum Coil belongs to the commercially pure wrought 1000 series of alloys with a purity of 99.5% aluminum. This alloy is usually used for cold rolling or extrusion. It has the characteristics of high plasticity, corrosion resistance, electrical conductivity, and thermal conductivity.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

Dear Sir, Please offer your best FOB Prices specs are as under ALUMINIUM STRIP (AL=99.50% MIN) SIZE:450 X32 X6 MM. DIN EN 570 EN-AW 1050 A, QUANTITY=3400KG

Hello, Would you be so kind to offer item as follows: Coil 0,6х1250 (1000)mm EN AW-3105 5tons

Hello, Can you offer me Aluminium plates? Actally I need: 110mm x 1700mm x 1700mm 5083 H111 - 21 pcs Next year planed is 177 pcs

Świetny artykuł. Byłem zachwycony, że wyszukałem ten artykuł. Wielu osobom wydaje się, że mają rzetelną wiedzę na ten temat, ale często tak nie jest. Stąd też moje miłe zaskoczenie. Jestem pod wrażeniem. Zdecydowanie będę rekomendował to miejsce i częściej wpadał, aby zobaczyć nowe rzeczy.

requirement of aluminium strip