"Tank truck aluminum plate" is a special aluminum alloy plate, which refers to the aluminum alloy plate used to manufacture the main structure or internal storage tanks of tank trucks (such as oil tank trucks, liquefied gas tank trucks, chemical transport tank trucks, etc.)

“Tank truck aluminum plate” is a special aluminum alloy plate, which refers to the aluminum alloy plate used to manufacture the main structure or internal storage tanks of tank trucks (such as oil tank trucks, liquefied gas tank trucks, chemical transport tank trucks, etc.). This type of aluminum plate needs to have specific performance characteristics to meet the safety and durability requirements of tank trucks during transportation.

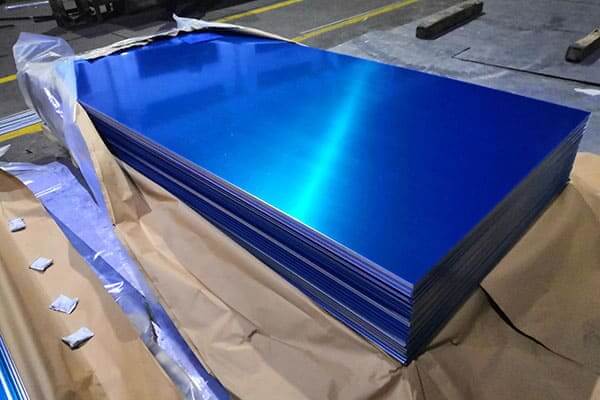

Aluminum plate for tank truck

Tank truck is a transport vehicle with a tank-shaped body, used to carry various liquids, liquefied gases, powdery goods, etc. The body of the aluminum alloy tank truck is composed of side panels, fenders, tank mouth and other parts.

The aluminum plates commonly used for tank trucks on the market are generally less than 12.5 meters in length and less than 2.2 meters in width. Common thicknesses are 5mm, 6mm, 7mm, and 8mm. A complete tank truck body usually requires 4-6 aluminum plates welded together.

| Alloy | Composition | Properties | Applications |

| 5083 | Al: 95.4%, Mg: 4.0%, Mn: 0.7%, Cr: 0.15% | Excellent corrosion resistance, weldability, and high strength-to-weight ratio. | Tank truck bodies and trailers due to its high strength and resistance to corrosion. |

| 5454 | Al: 95.3%, Mg: 2.7%, Mn: 0.7%, Cr: 0.12% | Good corrosion resistance, weldability, and high fatigue strength. | Tank truck bodies and trailers where high strength and corrosion resistance are required. |

| 5182 | Al: 95.2%, Mg: 0.9%, Mn: 0.5%, Fe: 0.35%, Si: 0.25%, Cr: 0.15% | Excellent weldability, formability, and corrosion resistance. | Tank truck bodies and trailers due to its formability and resistance to corrosion. |

| 5754 | Al: 97.6%, Mg: 2.6%, Mn: 0.3%, Cr: 0.2% | Good corrosion resistance, weldability, and high strength. | Tank truck bodies and trailers where high strength and corrosion resistance are required. |

| 6061 | Al: 97.9%, Mg: 0.6%, Si: 0.6%, Cu: 0.28%, Cr: 0.2% | Good corrosion resistance, weldability, and high strength. | Tank truck bodies and trailers where high strength and corrosion resistance are required. |

The can body is made of 5083-H111 aluminum plate, and the lids on both sides are made of 5083-O aluminum plates. The O-temper is softer, but the lid needs to be bent, and the partition part is also made of 5083-O. In addition, some manufacturers use 5454-H111 aluminum plates to produce tanks.

5083 aluminum sheet for tank truck

| Alloy | 5083 5454 5182 3003 6061 6063 |

| Welding wire | ER5183 ER5356 |

| Aluminum plate thickness | 3-10mm |

| Aluminum plate width | 1000-2650mm |

| Aluminum plate length | 2000-16000mm |

| Aluminum profile product shape | L type, T type, round tube, triangular beam etc. |

| Surface treatment | Mill finish, bright mirror finish |

| Tanker material aluminum thickness | 6mm, 5mm |

| Bulkhead and baffle thickness | 7mm |

| Tanker shell thickness | 6mm & 5mm |

| Shape of tanker Ellips | double “d” |

| Manhole 20″ aluminum alloy manhole cover | C801-560 |

Alloy selection and optimization:

Choose corrosion-resistant aluminum alloys: Choose aluminum alloys containing appropriate amounts of magnesium, manganese, chromium, silicon and other elements, such as 5000 series aluminum alloy (containing magnesium), 6XXX series (containing magnesium and silicon) or part of the 7XXX series (containing zinc). These alloys have Better natural corrosion resistance.

Alloy purity: Improving the purity of aluminum alloys and reducing the content of impurity elements, especially iron, copper and other elements that easily cause corrosion, will help improve the overall corrosion resistance.

Tank truck aluminum plate

Surface treatment:

Anodizing: Anodize the surface of aluminum alloy to form a dense aluminum oxide film (Al₂O₃) to improve its corrosion resistance and wear resistance. The color of the anodized film can be controlled by adjusting process parameters, and has a good decorative effect.

Special coating: Select special coating suitable for aluminum alloy, such as epoxy resin, polyurethane, fluorocarbon coating, etc., to ensure good adhesion and anti-corrosion performance between the coating and the aluminum alloy substrate. Coatings should have good chemical resistance, weather resistance and mechanical properties.

maintenance:

Regular inspection: Establish a regular inspection system to conduct visual inspection, thickness measurement, corrosion monitoring, etc. on the surface of the tank to promptly detect and repair coating damage and corrosion signs.

Cleaning and protection: After transporting special media, thoroughly clean the inside of the tank to remove residues, and take appropriate methods (such as drying, nitrogen filling, etc.) to prevent moisture retention and corrosion.

Repair and recoating: Once corrosion or coating damage is found, anti-corrosion treatments such as rust removal, repair, and recoating should be carried out in a timely manner.

Due to the particularity of transporting goods, tank trucks must avoid problems such as tank cracks. This requires the aluminum plate to have strong resistance to stress cracking. Chinalco’s cold rolling project uses a German Simark six-roller cold rolling mill to eliminate internal stress, prevent deformation during cutting, and effectively avoid cracking problems.

The price of aluminum plate for tank cars will vary based on several factors, including the alloy type, thickness, size, surface treatment and market supply and demand of the aluminum plate.

Generally speaking, the price of aluminum plates will vary according to the type of alloy. The price of alloys with high strength and better corrosion resistance may be higher.

In addition, the thickness and size of the aluminum plate will also affect the price. Aluminum plates with thicker thickness and larger size will usually be more expensive. Surface treatment will also affect the price, such as anodizing, mirror treatment, painting treatment, etc., which will increase the cost.

For specific tank truck aluminum plate prices, please contact us

Whatsapp: https://api.whatsapp.com/send?phone=8618137782032

Email: [email protected]

040 Aluminum Sheet is a type of aluminum sheet that has a thickness of 0.04 inches, which is equivalent to 1.016 millimeters. It is a thin and lightweight material

Aluminum Foil For Hair Salon The most common 8011 alloy O Temper, because of excellent strength, flexibility, and heat resistance, Henan Huawei provides you with the best quality 8011-0 aluminum foil for hair salon.

5005 aluminum coil refers to the 5005 aluminum plate after being cast and rolled and then processed into a coil shape by drawing and bending,

5000 series aluminum alloy is an Al-Mg alloy series with high strength and excellent corrosion resistance. It is commonly used in the manufacturing of marine, oil tanks, ships, automobile, building materials and other fields.

Cigarette aluminum foil has properties such as moisture-proof, anti-oxidation, and heat insulation. It is mainly used to protect the quality of cigarettes and maintain the humidity of cigarettes.

Electronic aluminum foil is a kind of aluminum foil processed by a series of rolling, cleaning and cutting processes of high-purity aluminum ingots. It is a key raw material for the production of aluminum electrolytic capacitors.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

Dear Sir, Please offer your best FOB Prices specs are as under ALUMINIUM STRIP (AL=99.50% MIN) SIZE:450 X32 X6 MM. DIN EN 570 EN-AW 1050 A, QUANTITY=3400KG

Hello, Would you be so kind to offer item as follows: Coil 0,6х1250 (1000)mm EN AW-3105 5tons

Hello, Can you offer me Aluminium plates? Actally I need: 110mm x 1700mm x 1700mm 5083 H111 - 21 pcs Next year planed is 177 pcs

Świetny artykuł. Byłem zachwycony, że wyszukałem ten artykuł. Wielu osobom wydaje się, że mają rzetelną wiedzę na ten temat, ale często tak nie jest. Stąd też moje miłe zaskoczenie. Jestem pod wrażeniem. Zdecydowanie będę rekomendował to miejsce i częściej wpadał, aby zobaczyć nowe rzeczy.

requirement of aluminium strip