Aluminum alloys are widely used in a variety of industries due to their high strength-to-weight ratio, excellent corrosion resistance, and good thermal and electrical conductivity. These alloys are composed of a combination of aluminum and other metals, such as copper, zinc, magnesium, and silicon, to achieve specific properties and characteristics. In this article, we will compare two popular aluminum alloys: 3003 aluminum and 6061 aluminum.

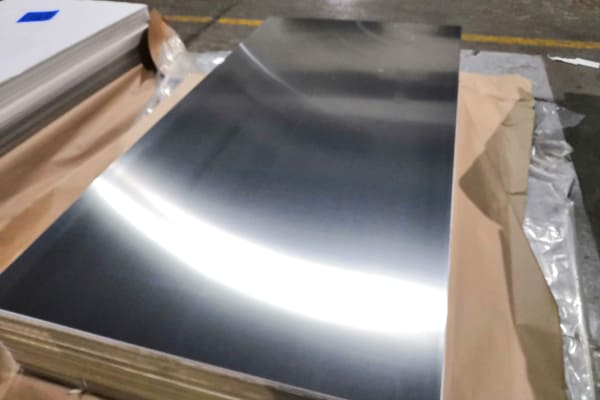

3003-h24-aluminum-sheet

3003 aluminum is a non-heat-treatable alloy that contains manganese as its primary alloying element. This alloy has excellent workability, high resistance to corrosion, and good weldability. 3003 aluminum is commonly used in the construction of heat exchangers, storage tanks, and pressure vessels. It is also used for roofing and cladding in the building and construction industry.

Composition and Properties of 3003 Aluminum

3003 aluminum is composed of 97.5% aluminum, 0.1% copper, 1.2% manganese, and 1.2% zinc. This alloy has a density of 2.73 g/cm3, a melting point of 655°C, and a thermal conductivity of 204 W/m-K. 3003 aluminum has an ultimate tensile strength of 125-185 MPa and a yield strength of 55-110 MPa.

6061 aluminum is a heat-treatable alloy that contains magnesium and silicon as its primary alloying elements. This alloy has good machinability, excellent corrosion resistance, and high strength. 6061 aluminum is commonly used in the manufacture of aircraft structures, automotive parts, and bicycle frames.

Composition and Properties of 6061 Aluminum

6061 aluminum is composed of 97.9% aluminum, 0.6% silicon, 1.0% magnesium, and 0.28% copper. Density of 6061 aluminum is 2.7 g/cm3, a melting point of 582-651°C, and a thermal conductivity of 151-202 W/m-K. 6061 aluminum has an ultimate tensile strength of 290-320 MPa and a yield strength of 240-260 MPa.

6061 aluminum

3003 aluminum has a lower density than 6061 aluminum, which makes it lighter and more suitable for applications that require a low weight-to-volume ratio. However, 6061 aluminum has a higher strength-to-weight ratio, which makes it more suitable for applications that require a high load-bearing capacity.

3003 aluminum has a lower ultimate tensile strength and yield strength than 6061 aluminum, which makes it less suitable for applications that require high strength and durability. However, 3003 aluminum has better formability and ductility than 6061 aluminum, which makes it more suitable for applications that require complex shapes and bending.

Both 3003 aluminum and 6061 aluminum have excellent corrosion resistance, with 3003 aluminum being more resistant to corrosion than 6061 aluminum in certain environments. However, 6061 aluminum has better resistance to stress corrosion cracking and pitting corrosion than 3003 aluminum.

More detials abou 6061 aluminium alloy

The advantages of 3003 aluminum include its excellent formability, high resistance to corrosion, and good weldability. Its disadvantages include its lower strength and load-bearing capacity compared to 6061 aluminum.

The advantages of 6061 aluminum include its high strength-to-weight ratio, excellent corrosion resistance, and good machinability. Its disadvantages include its lower formability and ductility compared to 3003 aluminum.

3003 aluminum is commonly used in the construction of heat exchangers, storage tanks, and pressure vessels due to its high resistance to corrosion. It is also used for roofing and cladding in the building and construction industry, as well as for cooking utensils and food processing equipment due to its non-toxic and non-reactive properties.

6061 aluminum is commonly used in the manufacture of aircraft structures, automotive parts, and bicycle frames due to its high strength-to-weight ratio. It is also used for marine and transportation applications, as well as for structural and architectural components in the building and construction industry.

When choosing between 3003 aluminum and 6061 aluminum, it is important to consider the specific requirements of your application. Factors to consider include the desired strength, weight, corrosion resistance, formability, and cost of the alloy.

For applications that require a high load-bearing capacity, such as aircraft structures and automotive parts, 6061 aluminum is a better choice due to its high strength-to-weight ratio. For applications that require excellent formability and ductility, such as cooking utensils and food processing equipment, 3003 aluminum is a better choice.

The cost of each alloy will depend on factors such as the specific grade of the alloy, the quantity ordered, and the current market prices. In general, 3003 aluminum is less expensive than 6061 aluminum due to its lower alloying content.

In conclusion, both 3003 aluminum and 6061 aluminum have their advantages and disadvantages, and the choice between the two will depend on the specific requirements of your application. By considering factors such as strength, weight, corrosion resistance, formability, and cost, you can make an informed decision about which alloy is best suited for your needs.

5454-O aluminium circle represents 5454 aluminum alloy O temper aluminum circle, belongs to 5000 series aluminum alloy.

In general, aluminum sheet that is thicker than 6mm (0.25 inches) is considered to be thick.

Anodized aluminum sheet is an aluminum sheet placed in the corresponding electrolyte (such as sulfuric acid, chromic acid, oxalic acid, etc.) as an anode, and electrolysis is performed under specific conditions and the action of external current.

As one of the main aluminium circle manufacturers in the Chinese market, our aluminium circle are made with the best raw materials and machinery, the main products include 1000 series, 3000 series, 5000 series and 8000 series, with an output of more than 5000 tons/month

5052 aluminum sheet is part of the 5000 series of aluminum. The grades in this series are alloyed with magnesium (2.5%) and have medium to high strength properties.

The properties of 3003 aluminum circle make it ideal for use in multiple markets including the cookware, automotive and lighting industries

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

Dear Sir, Please offer your best FOB Prices specs are as under ALUMINIUM STRIP (AL=99.50% MIN) SIZE:450 X32 X6 MM. DIN EN 570 EN-AW 1050 A, QUANTITY=3400KG

Hello, Would you be so kind to offer item as follows: Coil 0,6х1250 (1000)mm EN AW-3105 5tons

Hello, Can you offer me Aluminium plates? Actally I need: 110mm x 1700mm x 1700mm 5083 H111 - 21 pcs Next year planed is 177 pcs

Świetny artykuł. Byłem zachwycony, że wyszukałem ten artykuł. Wielu osobom wydaje się, że mają rzetelną wiedzę na ten temat, ale często tak nie jest. Stąd też moje miłe zaskoczenie. Jestem pod wrażeniem. Zdecydowanie będę rekomendował to miejsce i częściej wpadał, aby zobaczyć nowe rzeczy.

requirement of aluminium strip