The hardness of 1000-8000 series alloy aluminum sheets is closely related to the alloy composition, processing technology and heat treatment. However, the hardness of different series of aluminum alloys is different.

The hardness of aluminum alloys is closely related to the alloy composition, processing technology and heat treatment. However, the hardness of different series of aluminum alloys is different. The following is the difference between aluminum alloy series that we have summarized through our long-term research on aluminum alloy series. Analysis of hardness.

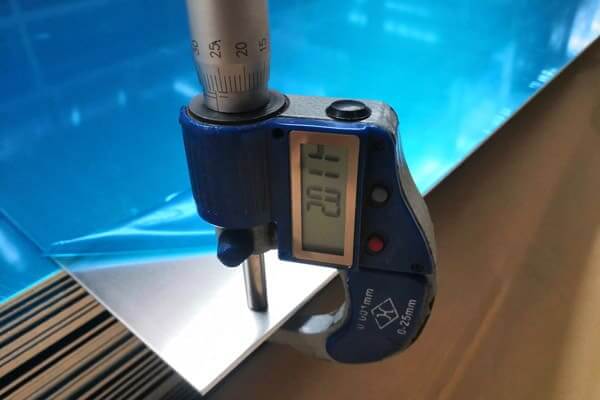

Hardness Of 1000-8000 Series Alloy Aluminum Sheets

The 1000 series aluminum plate belongs to the series of products containing the most aluminum among the entire aluminum plate series. The basic aluminum content is maintained above 99.00%, which is usually called 1000 series pure aluminum;

The 1000 series aluminum plate has a relatively simple production technology, and its price is basically the lowest among the entire aluminum alloy series. The hardness of the 1 series alloy aluminum plate is the lowest among the entire series, and the ordinary plate is more suitable for stamping or decoration purposes.

1000 series aluminum sheets are suitable for applications where strength is not required, and their softness makes them ideal for forming, welding and applications requiring high corrosion resistance, such as food packaging.

The 2000 series alloy aluminum plate is the product with the highest hardness in the all series. The advantage of the 2000 series is its high hardness, especially for stamping parts and parts. 2000 series aluminum alloys will be preferred, such as 2A16/2A06, which are the leading products of the 2000 series, this brand of aluminum alloy is also used in automobile wheels.

The 3000 series aluminum plate is basically a rust-proof aluminum plate, and its hardness is harder than 1000 series aluminum plate. Because the manganese element in 3000 series aluminum plates is high, the basic proportion is about 1-1.5%, and the price is slightly higher than that of 1000 series aluminum alloys;

Therefore, 3000 series aluminum alloys are widely used and are generally used in fields where the hardness requirements are slightly higher than those of 1000 series aluminum alloys.

The 4000 series is generally a series with a high proportion of silicon element. It is often called Al-Si alloy. Basically, the silicon content can reach 4.5% to 6.0%. However, the 4000 series products are used less, and most of them are used more for products that require low melting point and good corrosion resistance. Because the advantages of 4000 series alloy aluminum plates are heat resistance, wear resistance and corrosion resistance.

The 5000 series aluminum plate is a hot-rolled aluminum plate and has similar uses to the conventional 1000 series and 3000 series aluminum plates. It is generally based on aluminum-magnesium alloy, with a magnesium content of 3-5%. As a common aluminum plate in our lives, 5000 series is widely used in various fields due to its advantages of low density, high elongation and high tensile strength. Moreover, the 5000 series alloy aluminum plate has moderate hardness and mature technology.

4×8 5052-H32 Aluminum Sheet With 2Mm

5000 series aluminum alloy is a medium-strength aluminum alloy material.

The 6000 series aluminum plate is an all-in-one aluminum plate and strip. It basically combines the product advantages of the 4000 series and the 5000 series. The 6000 series alloy aluminum plate has high hardness, corrosion resistance, and forging resistance. In particular, it has good oxidation effect and high aesthetics.

The 6000 series aluminum alloy can be strengthened through heat treatment. The processed state is T4, T6, T651. The 6000 series aluminum alloy strengthened by heat treatment has higher strength.

7000 series aluminum plate is an aviation series aluminum plate, and the main alloy element is zinc. Among the products after the 2000 series, the alloy aluminum plate has the highest hardness. At the same time, the 7000 series aluminum plate contains aluminum, magnesium, zinc, and copper alloys and does not deform after processing. It has high hardness and high strength.

8000 series alloy aluminum plates belong to other series, so the hardness of 8000 series alloy aluminum plates generally does not fall into this comparison category. Because 8000 series alloy aluminum plates are mainly used for bottle cap materials or aluminum foil, there are not many customers who have separate needs in the field of civilian processing.

In summary, as the series number increases, the hardness of aluminum alloys does not strictly increase or decrease, but has its own characteristics according to different alloy compositions and processing techniques. Among them, the 2000 and 7000 series tend to have the highest hardness, while the 1000 series is the softest. Although the hardness of the 5000 and 6000 series is not as good as these two series, they are widely used in practical applications due to their excellent overall performance.

The 3000 series aluminum alloy6063 aluminum sheet is a medium-strength aluminum alloy with excellent price and excellent performance. It is also an extremely widely used aluminum alloy material.

Hardness is not the only factor that determines the suitability of alloy plates. When choosing the best series, consider your specific requirements for strength, weight, corrosion resistance and formability.

The temper designation has a significant impact on the hardness of each series. Be sure to consult a reference sheet or material data sheet for the precise hardness value for a specific temper condition.

Welcome to Huawei Aluminum, your trusted source for high-quality aluminum coils designed specifically for aluminium roofing sheets.

Huawei Aluminum is your reliable partner for 1070 Aluminum Coil products. With our commitment to quality, customization, and competitive pricing, we aim to meet and exceed your expectations.

5005 aluminum coil refers to the 5005 aluminum plate after being cast and rolled and then processed into a coil shape by drawing and bending,

5×10 aluminum sheet is a common specification of aluminum sheet produced by aluminum sheet manufacturers,it is 5 feet wide and 10 feet long.

3005 aluminum plate belongs to Al-Mn alloy. The strength of 3005 aluminum plate is about 20% higher than that of 3003 aluminum plate, and its corrosion resistance is also better.

Perforated aluminum sheets are made by aluminum sheets that have been machined with round holes (or other designs). The holes can be in line or staggered to increase the number of openings.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

Dear Sir, Please offer your best FOB Prices specs are as under ALUMINIUM STRIP (AL=99.50% MIN) SIZE:450 X32 X6 MM. DIN EN 570 EN-AW 1050 A, QUANTITY=3400KG

Hello, Would you be so kind to offer item as follows: Coil 0,6х1250 (1000)mm EN AW-3105 5tons

Hello, Can you offer me Aluminium plates? Actally I need: 110mm x 1700mm x 1700mm 5083 H111 - 21 pcs Next year planed is 177 pcs

Świetny artykuł. Byłem zachwycony, że wyszukałem ten artykuł. Wielu osobom wydaje się, że mają rzetelną wiedzę na ten temat, ale często tak nie jest. Stąd też moje miłe zaskoczenie. Jestem pod wrażeniem. Zdecydowanie będę rekomendował to miejsce i częściej wpadał, aby zobaczyć nowe rzeczy.

requirement of aluminium strip