How to polishing aluminum

Polishing aluminum can restore its shine and remove oxidation. Here’s a step-by-step guide:

Materials Needed:

- Polish aluminum or metal polish

- Soft cloths or microfiber towels

- Sandpaper (fine grit, optional for deep scratches)

- Aluminum cleaner (optional)

- Gloves (optional)

- Wheel (if using a power tool)

Steps :

- Clean the Surface:

- Start by washing the aluminum with soap and water to remove dirt and grime. You can also use an aluminum cleaner if necessary.

- Rinse and dry completely.

- Inspect the Surface:

- Check for any scratches or oxidation. If the aluminum is heavily oxidized, you might need to sand it lightly with fine-grit sandpaper (e.g., 600 grit) to smooth the surface.

- Apply Polish:

- Choose an aluminum or metal polish. Apply a small amount to a soft cloth or directly to the aluminum surface.

- Rub it in with circular motions, working in small sections.

- Buff the Surface:

- After applying the polish, buff the area with a clean cloth to remove excess polish and enhance the shine.

- Repeat this process until you achieve the desired shine.

- Final Touch:

- For extra protection, consider applying a wax or sealant designed for aluminum. This will help maintain the shine and protect against future oxidation.

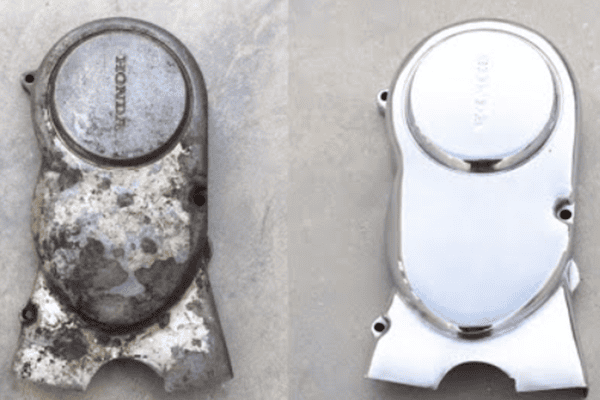

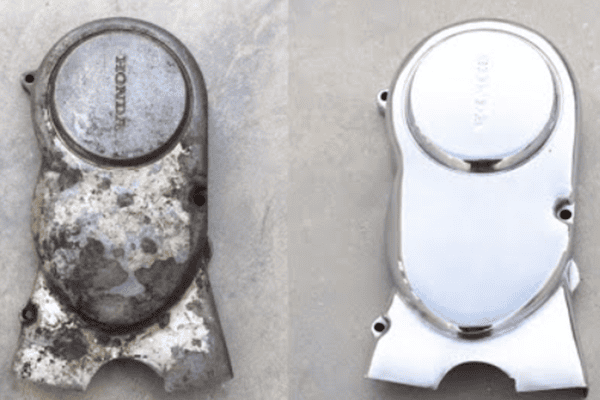

Polishing aluminum process

Tips:

- Always test the polish on a small, inconspicuous area first.

- Use gloves if you’re sensitive to chemicals in the polish.

- For larger projects or intricate designs, consider using a polishing wheel with a power tool for a more even finish.

Sure! Here’s the translation:

Benefits of Polishing Aluminum

- Aesthetic Enhancement

- Polished aluminum has a smooth, shiny surface that enhances visual appeal, suitable for decoration and product display.

- Removal of Oxidation

- The polishing process removes oxidation from the aluminum surface, preventing further corrosion and extending its lifespan.

- Ease of Cleaning

- The smooth surface is less likely to attract dirt and grease, making cleaning and maintenance simpler.

- Improved Heat Dissipation

- Polished aluminum surfaces can dissipate heat more effectively, helping to improve the performance of radiators and electronic components.

- Reduced Friction

- In mechanical applications, polished aluminum can lower friction, enhancing efficiency and prolonging equipment lifespan.

- Higher Market Value

- Polished aluminum products typically have a higher value and competitiveness in the market.

Polishing aluminum significantly improves its performance and appearance, making it advantageous in various applications.

Polished Aluminum Contrast

Common misconceptions about polishing aluminum

Here are some common misconceptions about polishing aluminum:

- Polishing Removes Metal

- Many believe that polishing significantly removes metal, but it primarily smooths and shines the surface without substantial loss of material.

- Any Polish Will Work

- Some think all metal polishes are interchangeable; however, specific products designed for aluminum yield the best results.

- Polishing Prevents Oxidation

- While polishing improves appearance, it doesn’t permanently prevent oxidation; regular maintenance is still required.

- Polished Aluminum Doesn’t Need Maintenance

- There’s a belief that polished aluminum is maintenance-free, but it requires periodic cleaning and re-polishing to maintain its shine.

- Polishing is Only for Aesthetics

- Many assume polishing is purely cosmetic, but it also enhances performance by improving heat dissipation and reducing friction.

- Once Polished, It Stays Shiny Forever

- People often think that a polished surface will remain shiny indefinitely, but environmental factors can dull it over time.

- You Can’t Polish Aluminum with Power Tools

- Some believe that polishing must be done by hand; however, power tools can be effectively used for larger or more intricate pieces when done correctly.

Understanding these misconceptions can help in achieving better results and maintaining aluminum surfaces effectively.

There are several ways to polishing aluminum

There are six main methods of aluminum polishing: mechanical polishing, chemical polishing, electrolytic polishing, ultrasonic polishing, fluid polishing and magnetic grinding polishing.

- 1. Mechanical polishing: Mechanical polishing is to grind and polish the surface of aluminum parts by using grinding equipment, such as grinding machines, polishing machines, etc., with sandpaper, grinding wheels and polishing pastes of different particle sizes. This method is suitable for aluminum parts with larger areas and rougher surfaces. Ultra-fine grinding and polishing can be used for those with high surface quality requirements.

- 2. Chemical polishing: Chemical polishing is to dissolve and corrode the surface of aluminum parts with chemical solutions to achieve a smooth and bright effect. Commonly used chemical polishing solutions contain phosphoric acid, sulfuric acid, nitric acid and other components. This method does not require complex equipment, can polish aluminum alloy parts with complex shapes, and has high efficiency.

- 3. Electrolytic polishing: Electrolytic polishing is to dissolve the microscopic raised parts on the surface of aluminum parts preferentially through electrolysis, thereby obtaining a smooth and flat surface. This method can obtain higher gloss and better corrosion resistance. The electrolytic polishing process is divided into two steps: macroscopic leveling dissolution and micro-leveling anode polarization.

- 4. Ultrasonic polishing: Ultrasonic polishing is to immerse the aluminum alloy parts in abrasive suspension and place them in an ultrasonic field, using the oscillation of ultrasonic waves for grinding and polishing. This method has little effect on the deformation of aluminum alloy parts, but it is difficult to make and install tooling.

- 5. Fluid polishing: Fluid polishing relies on high-speed flowing liquid and the abrasive particles it carries to flush the surface of aluminum alloy parts to achieve a polishing effect. Common methods include abrasive jet processing, liquid jet processing and fluid dynamic grinding.

- 6. Magnetic grinding and polishing: Magnetic grinding and polishing uses magnetic abrasives to form abrasive brushes under the action of a magnetic field to grind and polish aluminum alloy parts. This method has high processing efficiency, high-quality processing quality and easy-to-control process conditions.

Latest Comments

Dear Sir, Please offer your best FOB Prices specs are as under ALUMINIUM STRIP (AL=99.50% MIN) SIZE:450 X32 X6 MM. DIN EN 570 EN-AW 1050 A, QUANTITY=3400KG

Hello, Would you be so kind to offer item as follows: Coil 0,6х1250 (1000)mm EN AW-3105 5tons

Hello, Can you offer me Aluminium plates? Actally I need: 110mm x 1700mm x 1700mm 5083 H111 - 21 pcs Next year planed is 177 pcs

Świetny artykuł. Byłem zachwycony, że wyszukałem ten artykuł. Wielu osobom wydaje się, że mają rzetelną wiedzę na ten temat, ale często tak nie jest. Stąd też moje miłe zaskoczenie. Jestem pod wrażeniem. Zdecydowanie będę rekomendował to miejsce i częściej wpadał, aby zobaczyć nowe rzeczy.

requirement of aluminium strip