5052 aluminum alloy surface passivation process and corrosion resistance of passivation film. Effects of Cr2(SO4)3 concentration, K2ZrF6 active agent concentration and passivation time on passivation quality in passivation solution.

As a non-ferrous metal material with excellent comprehensive properties, aluminum alloy is widely used in aerospace, construction, automobile, mechanical equipment and other industries.

5052 aluminum alloy is light in weight and has good weldability, so it is often used in the preparation of aluminum alloy automotive fuel tanks, gas storage tanks, operating platforms and other parts in the automobile manufacturing industry. However, the standard electrode potential of aluminum alloy is low, and it is easy to cause micro-battery corrosion in a humid environment (especially in a chlorine-containing humid environment), which seriously affects the corrosion resistance of aluminum alloy materials, and has a negative impact on its service life and engineering applications. have a huge negative impact.

5052 aluminum alloy sheet with blue film

Surface electrochemical treatment and chemical treatment are common methods for aluminum alloy anticorrosion. Among them, electrochemical surface treatment of aluminum alloy has the disadvantages of complex equipment and high cost, and chemical passivation treatment has been widely used in recent years because of its low cost and high efficiency. application.

For 5052 aluminum alloy, an automotive exterior engineering material, it is still of great significance to seek a simple, low-cost and environmentally friendly corrosion passivation method.

Hexavalent chromium passivation is the most effective and most widely used chemical passivation. However, hexavalent chromium is toxic and carcinogenic, and has been gradually banned by more and more countries. In order to replace hexavalent chromium, researchers have successively developed technologies such as rare earth metal salt passivation, molybdate passivation, silicate passivation, and trivalent chromium salt passivation, among which the film-forming mechanism of hexavalent chromium is the same and non-toxic The trivalent chromium salt passivation performance is excellent, and it is most likely to replace the hexavalent salt passivation.

Although previous studies on the passivation of trivalent chromium are more, but less applied to aluminum alloys, and the key exterior parts of aluminum alloy automobiles have higher requirements for corrosion resistance, and trivalent chromium is suitable for adding organic complexing agents color passivation scheme. For this reason, on the basis of the previous research, this work selects the chemical passivation method of chromium sulfate salt with research potential, uses the addition of activator to improve the film quality, optimizes the passivation process parameters, and finally successfully develops an application Based on the trivalent chromium passivation process of 5052 aluminum alloy, the passivation film formed is continuous and uniform in silver white, uniform in color, good in gloss, excellent in corrosion resistance, non-polluting to the environment, and has a good application prospect .

| ρ[Cr2( SO4 ) 3]/ Test grade |

ρ( K2 ZrF6 ) / t / min |

||

| ( g·L-1 ) | ( g·L-1 ) | ||

| 1 | 1.0 | 2.5 | 4 |

| 2 | 3.0 | 2.5 | 4 |

| 3 | 5.0 | 2.5 | 4 |

| 4 5 |

7.0 5.0 |

2.5 1.0 |

4 4 |

| 6 | 5.0 | 4.0 | 4 |

| 7 | 5.0 | 5.5 | 4 |

| 8 | 5.0 | 2.5 | 1 |

| 9 | 5.0 | 2.5 | 2 |

| 10 | 5.0 | 2.5 | 3 |

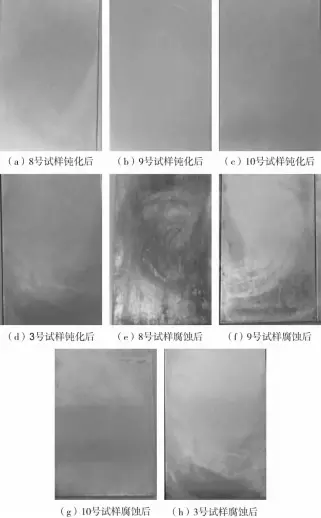

Based on the appearance requirements of automotive exterior parts, visually observe the passivation film formation, such as appearance color changes, film continuity and uniformity, and comprehensively evaluate the appearance quality of the passivation film.

According to the company’s requirements for 240h salt spray corrosion resistance of automotive aluminum alloy appearance parts, the test is carried out according to the neutral salt spray test (NSS test) method in GB/T10125-2012. The concentration of NaCl solution in the reagent is 5% (mass fraction), and the pH value is 6.5-7.2. The pressure of the saturated pressure chamber is 70-170kPa, the salt mist settlement per 80cm2 area is 1-2mL/h, and the test piece is 20° to the vertical direction.

The temperature of the test chamber is kept at (35±2)°C, and the spraying is continued for 10 days. At the end of the test, wash the surface of the finished product with water and a soft brush, dry it, take pictures with a digital camera, observe the corrosion of the test piece, and according to GB/T12335-1990 “The metal coating is anodic to the substrate after the coating corrosion test”. Specimen Rating”, by calculating the corrosion area to rate the degree of corrosion defects on the surface appearance of the specimen.

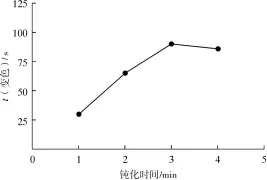

The corrosion resistance of aluminum alloy passivation film was tested by copper sulfate drop test. The composition of copper sulfate corrosion solution is 41g/L copper sulfate, 35g/LNaCl, 13mL/LHCl. In the test, use a dropper to drop a drop of copper sulfate corrosion solution on the surface of the sample at room temperature, observe the color change of the droplet, that is, the color changes from sky blue to black, and record the time of color change. The spot test of each sample takes the average value of the data of 5 different areas. The length of time can reflect the pros and cons of the corrosion resistance of the passivation film.

In the passivation test, chromium sulfate, as a film-forming substance, affects the surface corrosion resistance by affecting the composition and structure of the conversion film.

Macroscopic morphology of aluminum alloy sample

Good film-forming quality depends on the matching between chromium sulfate and surfactant. Due to the increase of chromium sulfate concentration and insufficient amount of surfactant K2ZrF6, the surface activity is weakened, so the bonding between film-forming molecules and the matrix is weakened, making passivation The film forming is not complete, and the film quality becomes poor, which in turn makes the film durable Corrosion decline.

K2ZrF6 is used as the surface active component in the passivation solution, and its concentration also has an important influence on the film quality. In the passivation test, the main function of potassium fluorozirconate is to reduce the surface tension of aluminum alloy, activate the surface of the alloy, promote the full reaction of chromium sulfate and the substrate to form a uniform and dense film, and improve its corrosion resistance.

The passivation time mainly affects the thickness of the conversion film, and as an industrial application, an appropriate passivation time can reduce costs and save resources.

Drip time of aluminium alloy sample plate at different time

1050 aluminum sheet is a kind of non-heat-treated aluminum plate, which has good plasticity, corrosion resistance, electrical conductivity and thermal conductivity after cold working;

The 6063 aluminum sheet is a 6000-series aluminum alloy with magnesium and silicon as the main alloying elements. The strength of the 6063 alloy is lower than that of the 6061 alloy, and it has good extrudability, corrosion resistance, and good surface treatment performance.

Anodized aluminum sheet is an aluminum sheet placed in the corresponding electrolyte (such as sulfuric acid, chromic acid, oxalic acid, etc.) as an anode, and electrolysis is performed under specific conditions and the action of external current.

Among the various aluminum alloys available, the 2014 aluminum plate has carved a niche for itself, particularly in applications demanding high strength, excellent machinability, and resistance to fatigue.

Heavy duty aluminum foil provides extra strength and tear resistance. Many cooks use it for baking, grilling, and storage. Most foil rolls marked "heavy duty" are between 0.0008" and 0.001" thick, which is roughly 0.02032-0.0254mm in national units

5086 aluminum sheet is a high-strength, corrosion-resistant al-mg alloy, widely used in aerospace, transportation, architectural decoration and other fields.

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

Dear Sir, Please offer your best FOB Prices specs are as under ALUMINIUM STRIP (AL=99.50% MIN) SIZE:450 X32 X6 MM. DIN EN 570 EN-AW 1050 A, QUANTITY=3400KG

Hello, Would you be so kind to offer item as follows: Coil 0,6х1250 (1000)mm EN AW-3105 5tons

Hello, Can you offer me Aluminium plates? Actally I need: 110mm x 1700mm x 1700mm 5083 H111 - 21 pcs Next year planed is 177 pcs

Świetny artykuł. Byłem zachwycony, że wyszukałem ten artykuł. Wielu osobom wydaje się, że mają rzetelną wiedzę na ten temat, ale często tak nie jest. Stąd też moje miłe zaskoczenie. Jestem pod wrażeniem. Zdecydowanie będę rekomendował to miejsce i częściej wpadał, aby zobaczyć nowe rzeczy.

requirement of aluminium strip