AL 5052 and AL 6061 have many similarities in chemical composition and performance. Both have strong corrosion resistance, good machinability, and good weldability. They are both known as marine grade aluminum.

AL 5052 and AL 6061 have many similarities in chemical composition and performance. Both have strong corrosion resistance, good machinability, and good weldability. They are both known as marine grade aluminum. In some application scenario, they can be substituted for each other;

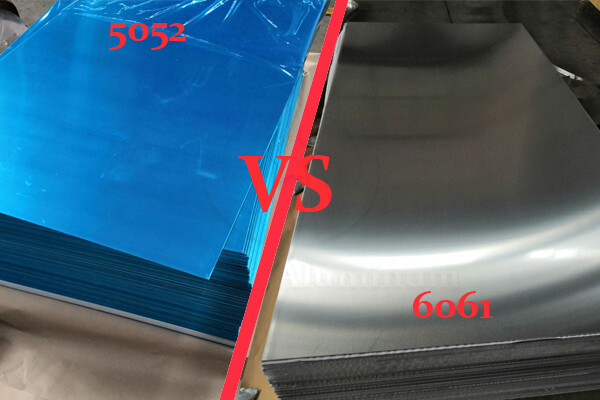

Diffirents with 5052 and 6061 alloy aluminum

I will introduce the difference between 5052 and 6061 aluminum:

5052 is a non-heat treated alloy, while AL 6061 can be strengthened by heat treatment;

The main synthetic elements of 6061 aluminum are magnesium (1.0%) and silicon (0.6%), and its strength is higher than that of AL 5052;

| Aluminum 6061 | Aluminum 5052 |

| Heat-treatable

Excellent machinability Excellent corrosion resistance Semi-smooth surface Lightweight High-tensile strength |

Non heat-treatable

Excellent weldability High corrosion resistance Smooth surface Lightweight High-tensile strength |

Many customers want to know the difference between 6061 t6 and aluminum 5052. 6061 aluminum alloy can produce T4, T5, T6, T651 and T6511 tempers. 5052 aluminum alloy is generally H112, H34, H32 and O state. Alloy 6061 is generally used in places with high strength, and alloy 5052 is generally used in places with low strength. The 5052 alloy pursues rust resistance, not strength. 552 aluminum plate and 6061 aluminum plate are both commonly used aluminum plates, but there are still very obvious differences.

5052 vs 6061 Aluminum

5052 aluminum sheet is part of the 5xxx series of aluminum. The grades in this series are alloyed with magnesium (2.5%) and have medium to high strength properties.

Aluminum 5052-h32 aluminium sheet can’t be hardened through heat treatment. However, it can be substantially hardened via coldworking strategies, inclusive of cold rolling.

Because of its low weight, high energy and attractive ends, corrosion-resistant 5052 aluminum sheets are ideal for a variety of marine packaging, including delivery construction, tank assembly, and oil line production.

Application of 5052 aluminum

5052 Aluminum For Pressure Vessel

6061 aluminum sheet is the most widely used heat-treatable aluminum sheet, the most common annealing state is T6, The T6 refers to the temper or degree of hardness, which is achieved by precipitation hardening. This grade has a good strength-to-weight ratio and is also heat-treatable.

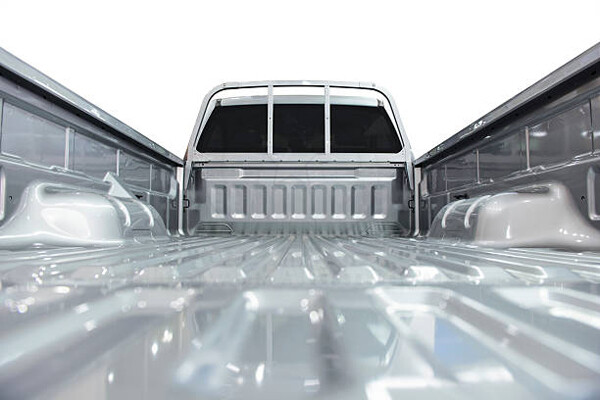

6061 aluminum sheet is used in tooling panels, construction applications, transportation equipment, bridge railing components, and can be used in welded structural applications., etc.

Application of 6061 aluminum

6061 Aluminum For Car

| Element | 5052 Aluminum | 6061 Aluminum |

| Aluminum | 95.85 – 97.70 % | 95.80 – 97.90 % |

| Silicon | 0.00 – 0.25 % | 0.40 – 0.80 % |

| Zinc | 0.00 – 0.10 % | 0.00 – 0.25 % |

| Magnesium | 2.20 – 2.80 % | 0.80 – 1.20 % |

| Manganese (Mn) | 0.00 – 0.10 % | 0.00 – 0.15 % |

| Chromium | 0.15 – 0.35 % | 0.04 – 0.35 % |

| Copper | 0.00 – 0.00 % | 0.15 – 0.40 % |

| Iron (Fe) | 0.00 – 0.40 % | 0.00 – 0.70 % |

| Titanium (Ti) | – | 0.00 – 0.15 % |

| Zirconium | – | – |

| Residuals | 0.00 – 0.15 % | 0.00 – 0.15 % |

| Properties | 5052 Aluminum | 6061 Aluminum | ||

| Units | English | Metric | English | Metric |

| Shear Modulus | 3760 ksi | 25.9 Gpa | 3770 ksi | 26.0 Gpa |

| Modulus of Elasticty | 10200 ksi | 70.3 Gpa | 10000 ksi | 68.9 Gpa |

| Fatigue Strength | 17000 psi | 117 Mpa | 14000 psi | 96.5 Mpa |

| Shear Strength | 20000 psi | 138 Mpa | 30000 psi | 207 Mpa |

| Electrical Resistivity | 3.99 x 10-6 ohm-cm | 5.15 x 10-6 ohm-cm | ||

| Machinability | Good | Fair | ||

| Hardness (Brinell) | 95 | 150 | ||

5052 and 6061 are two different grades of aluminum alloys with distinct properties and uses.

5052 aluminum alloy is a non-heat treatable alloy with good corrosion resistance and excellent welding characteristics. It is commonly used in marine and transportation applications, as well as in appliances and architectural applications.

6061 aluminum alloy, on the other hand, is a heat-treatable alloy with good machinability, weldability, and corrosion resistance. It is commonly used in structural and industrial applications such as aircraft components, bike frames, and heavy-duty structures.

In terms of strength, 6061 is stronger than 5052, but 5052 has better formability, surface appearance, and corrosion resistance. Additionally, 6061 has a higher percentage of silicon and magnesium, which makes it more difficult to weld compared to 5052.

1100 Aluminum Coil is the alloy with the highest commercial purity of all aluminum grades, with an aluminum content (mass fraction) of 99.00%. Its strength is relatively low, and it has excellent ductility, formability, weldability, and corrosion resistance.

3005 aluminum plate belongs to Al-Mn alloy. The strength of 3005 aluminum plate is about 20% higher than that of 3003 aluminum plate, and its corrosion resistance is also better.

3003 aluminum sheet is an alloy with very good corrosion resistance and moderate strength, the reason this metal is widely used is because it is affordable and strong.

Same as 1050 aluminum sheet, 1060 aluminum sheet also belongs to 1 series pure aluminum sheet,Commonly used in lithium battery soft connection, bus bar, road sign, charging pile, aluminum gasket, billboard building exterior wall decoration,and so on.

Our embossed aluminum foil products are exported to more than 60 countries and regions in the European Union, the Middle East, Southeast Asia, and South America, and enjoy a good reputation in the international market with the best service and high-quality products.

Upgrade your roof with high-quality aluminum roofing sheets. Experience long-lasting protection and enhance your home's aesthetics with our stylish and durable roofing solution

No.52, Dongming Road, Zhengzhou, Henan, China

Henan Huawei Aluminum Co., Ltd, One Of The Biggest Aluminum Supplier In China Henan,We Are Established In 2001,And We Have rich experience in import and export and high quality aluminum products

Mon – Sat, 8AM – 5PM

Sunday: Closed

© Copyright © 2023 Henan Huawei Aluminium Co., Ltd

Latest Comments

Dear Sir, Please offer your best FOB Prices specs are as under ALUMINIUM STRIP (AL=99.50% MIN) SIZE:450 X32 X6 MM. DIN EN 570 EN-AW 1050 A, QUANTITY=3400KG

Hello, Would you be so kind to offer item as follows: Coil 0,6х1250 (1000)mm EN AW-3105 5tons

Hello, Can you offer me Aluminium plates? Actally I need: 110mm x 1700mm x 1700mm 5083 H111 - 21 pcs Next year planed is 177 pcs

Świetny artykuł. Byłem zachwycony, że wyszukałem ten artykuł. Wielu osobom wydaje się, że mają rzetelną wiedzę na ten temat, ale często tak nie jest. Stąd też moje miłe zaskoczenie. Jestem pod wrażeniem. Zdecydowanie będę rekomendował to miejsce i częściej wpadał, aby zobaczyć nowe rzeczy.

requirement of aluminium strip